Heat-released welding die

An exothermic welding and mold technology, which is applied in the field of workpiece welding auxiliary devices, can solve problems such as the inability to remove the upper mold of the mold, and achieve the effect of avoiding safety accidents and accurate dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

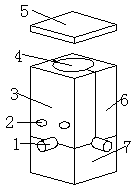

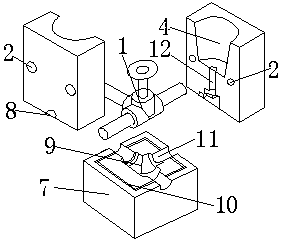

[0021] An exothermic welding mold comprises a left upper mold 3 and a lower mold 7; the inside of the upper mold 3 is provided with a reaction chamber 4 and a flow channel 12 for welding, and the contact surfaces of the upper mold 3 and the lower mold 7 are provided with There are welding cavities 9 matching each other, the reaction chamber 4 communicates with the welding cavities 9 through flow passages 12, and the periphery of the welding cavities 9 on the upper surface of the lower mold 7 is provided with strip grooves 10, The periphery of the welding cavity 9 on the lower surface of the upper mold 3 is provided with strip-shaped protrusions corresponding to the positions of the strip grooves 10, and the upper mold 3 is at least spliced by two components 6 that match each other, and The interfitting components 6 are detachably and fixedly connected to each other. The upper mold 3 is spliced by mutually matching components 6. During the welding process, when the solder i...

Embodiment 2

[0023] On the basis of Example 1, arc-shaped grooves 8 matching each other are provided on the contact surfaces of each component 6 of the upper mold 3 and the lower mold 7, and the arc-shaped grooves 8 are used for welding The cavities 9 are connected, and the arc-shaped groove 8 is also used to communicate with the sides of the upper mold 3 and the lower mold 7 . Each component 6 of the upper mold 3 and the arc-shaped groove 8 on the contact surface of the lower mold 7 form a circular through hole 11 on the side of the welding auxiliary device. This structure facilitates the welding of the workpiece 1 from the circular through hole 11 in or out.

Embodiment 3

[0025] On the basis of Examples 1-2, the longitudinal cross-sectional dimension of the strip-shaped protrusion is smaller than the longitudinal cross-sectional dimension of the strip-shaped groove 10 . The strip-shaped protrusions are used to fit in the strip-shaped grooves 10, and are used to ensure that each component 6 of the upper mold 3 does not shift with the lower mold 7, and ensure that the size of the welding cavity 9 is accurate, which is beneficial to welding without multiple times Only by adjusting the contact positions of each component 6 of the upper mold 3 and the lower mold 7 can the clamping of the upper mold 3 be carried out, which avoids the need to loosen and adjust the position of the welding cavity 9 after the upper mold 3 is clamped The trouble caused by re-clamping the upper mold 3, because the longitudinal cross-sectional dimension of the strip-shaped protrusion is smaller than the longitudinal cross-sectional dimension of the strip-shaped groove 10, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com