Efficient and safe gravel crushing device

A crushing device and safe technology, applied in the fields of removing smoke and dust, cleaning methods and utensils, grain processing, etc., can solve problems such as difficulty in adjusting the size of crushed products, unfavorable screening of sand and gravel, accelerated aging of components, etc., so as to improve service life and reduce Concentration, the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

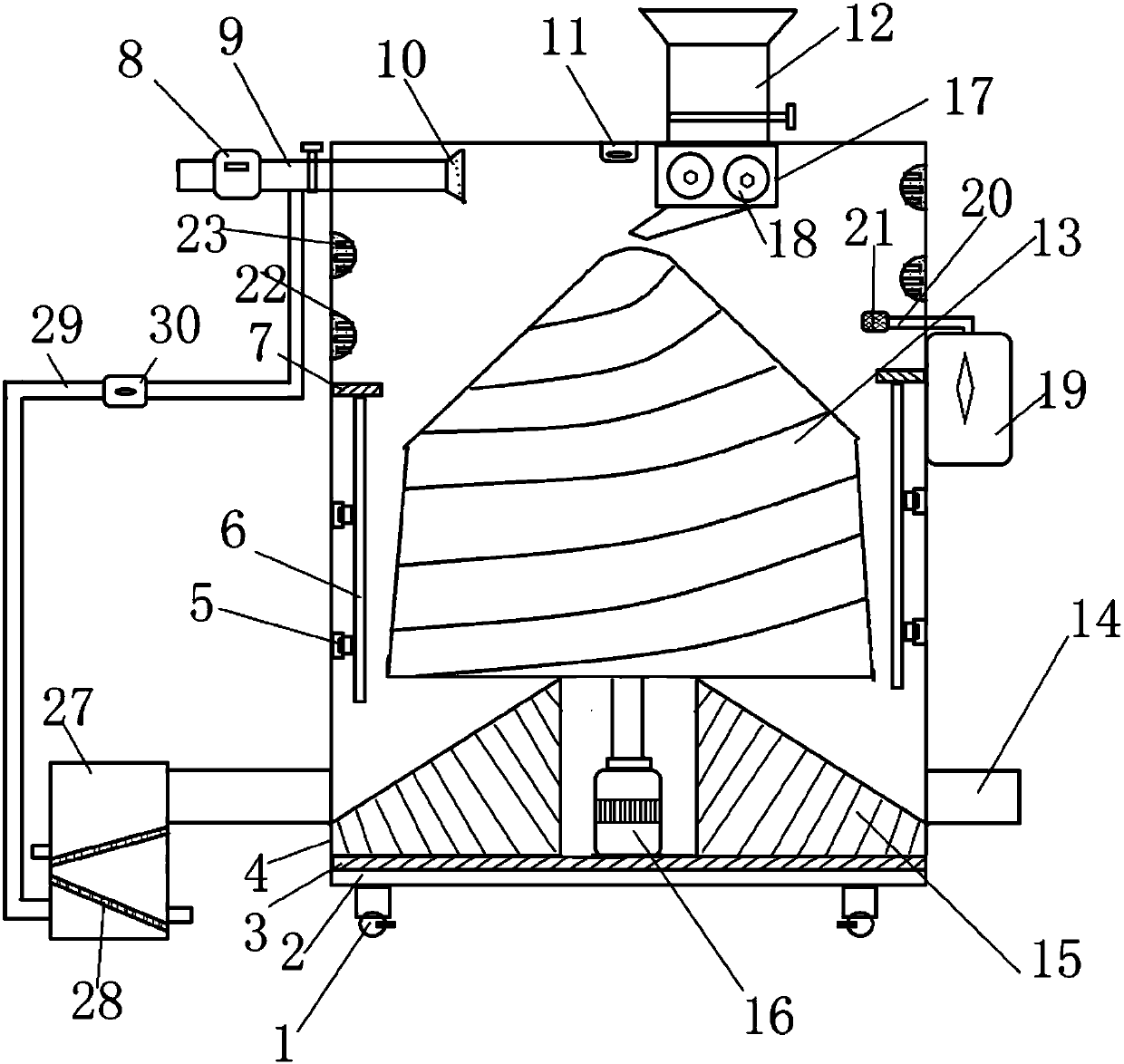

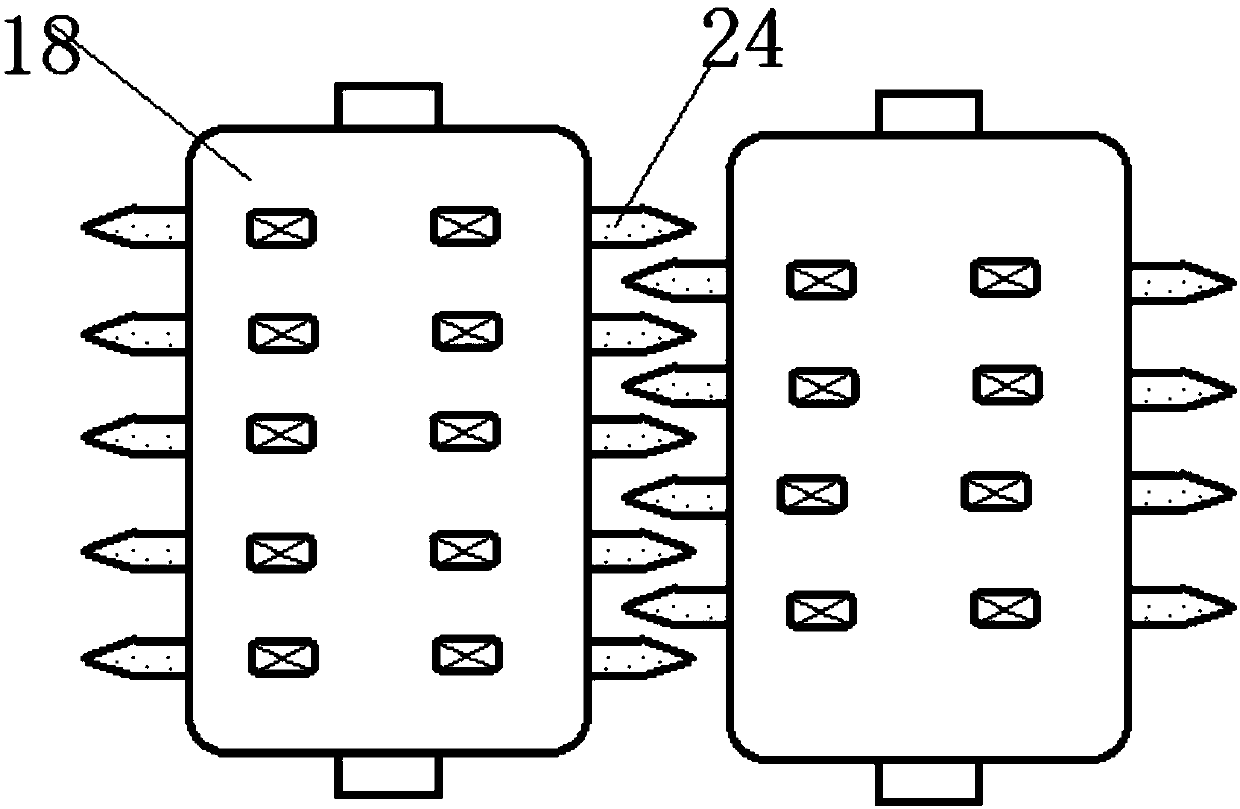

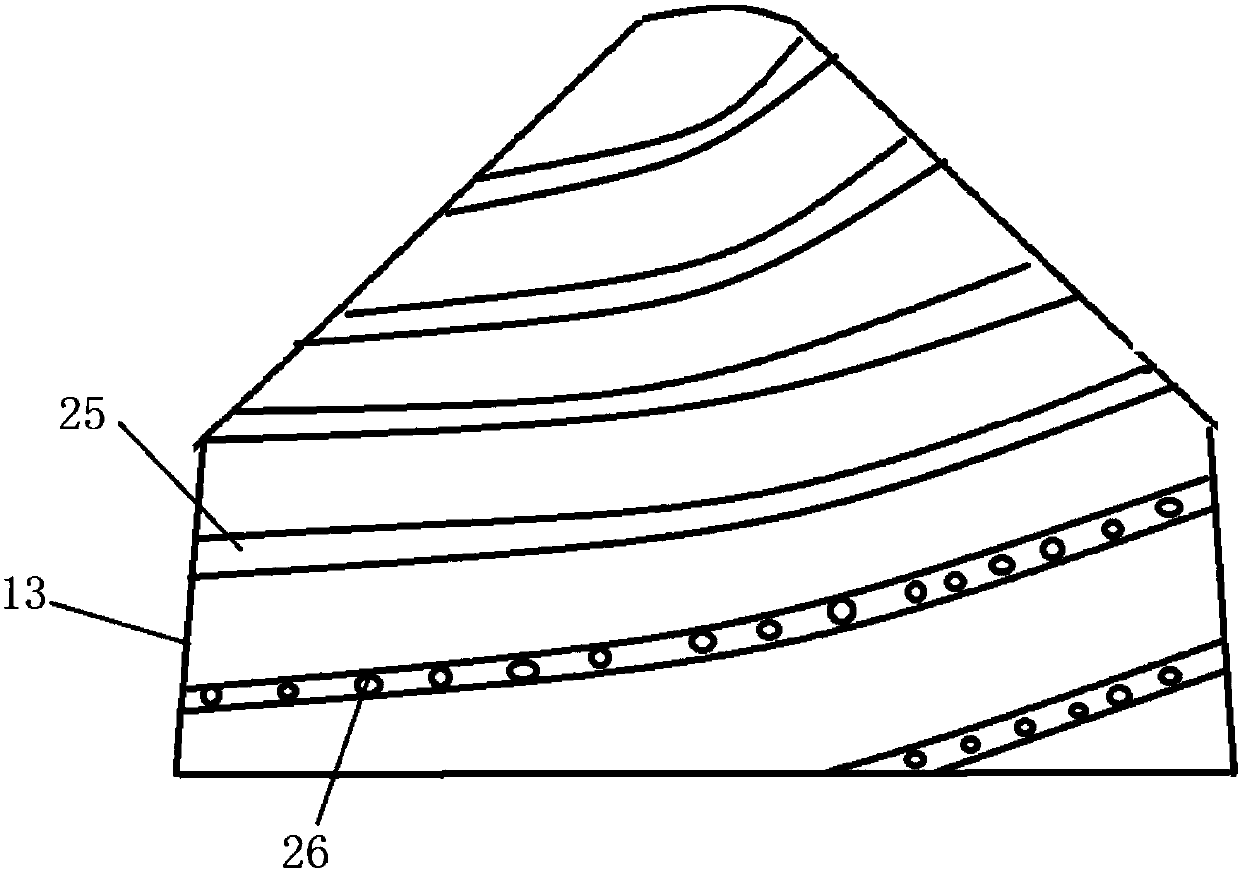

[0019] see Figure 1-4 , an efficient and safe gravel crushing device, including guide wheel 1, box body 4, telescopic rod 5, pressure bearing plate 6, baffle plate 7, flow meter 8, water inlet pipe 9, nozzle 10, camera 11, feed pipe 12 , crushing device 13, discharge pipe 14, inclined guide plate 15 and motor 16, the bottom surface of the box body 4 is provided with a guide wheel 1, the guide wheel 1 is provided with a handbrake, the guide wheel 1 is convenient for the device to move, saving time and effort, the box The bottom of the body 4 is provided with a moisture-proof plate 2 and a shock-absorbing plate 3. The moisture-proof plate 2 avoids the corrosion of the device by the accumulated water on the ground, and the shock-absorbing plate 3 reduces the damage to the device due to vibration and improves the service life. The top of the box body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com