Engine spray simulation calibration method and system

A calibration method and engine technology, applied in the direction of engine testing, engine components, machines/engines, etc., can solve problems such as errors, reduce the number of calibrations, and improve calculation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

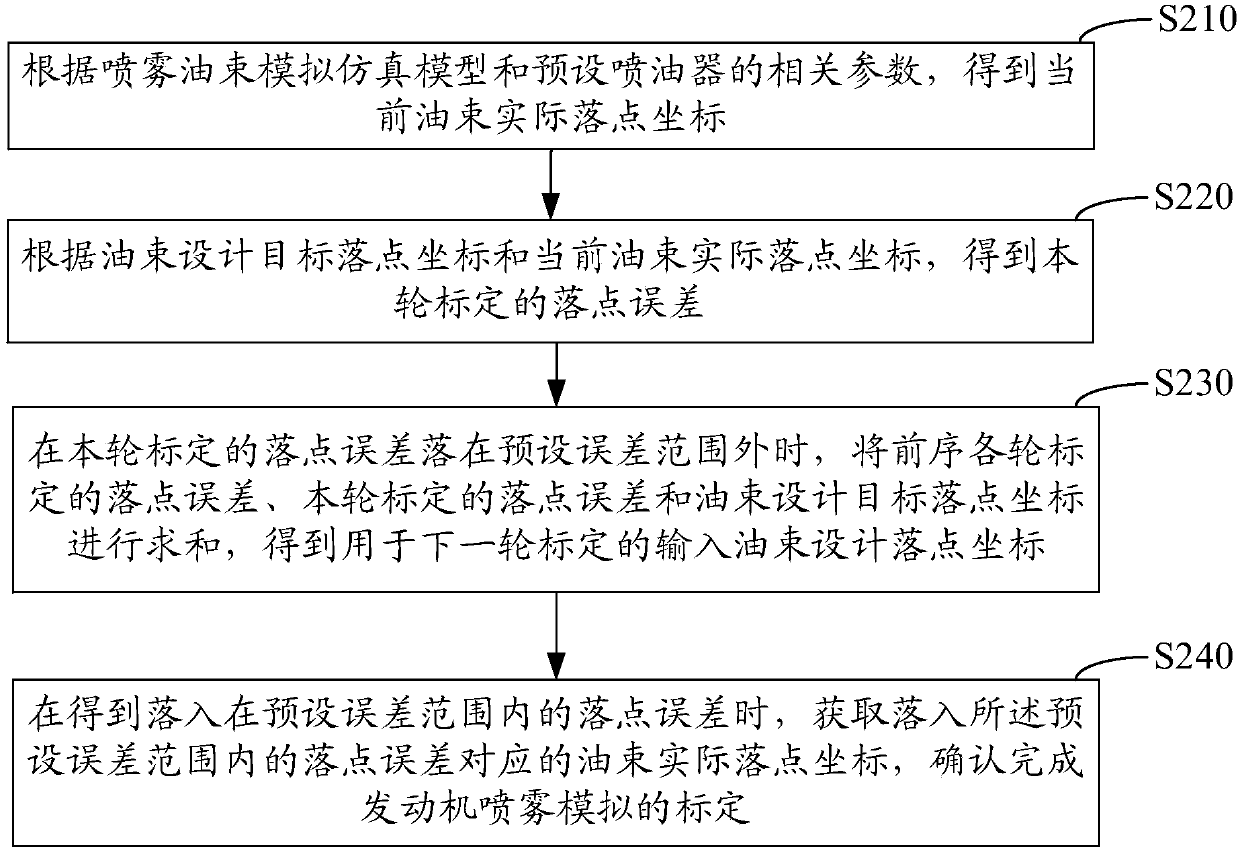

[0114] see Figure 8 As shown, it is a schematic structural diagram of the calibration system embodiment 1 of the engine spray simulation of the present invention, which may include:

[0115] The parameter input unit 810 is used to obtain the actual landing point coordinates of the current oil jet according to the spray oil jet simulation model and the relevant parameters of the preset fuel injector; the relevant parameters of the preset fuel injector include the coordinates of the current input oil jet landing point;

[0116] The landing point error acquisition unit 820 is used to obtain the landing point error of the current wheel according to the oil jet design target landing point coordinates and the current oil jet actual landing point coordinates; the oil jet design target landing point coordinates are the input oil jet landing point coordinates Coordinate initial value;

[0117] The iterative unit 830 is used to sum the landing point errors of the previous rounds, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com