Flange workpiece clamping device

A clamping device and workpiece technology, which is applied to used abrasive processing devices, manufacturing tools, metal processing equipment, etc., can solve the problems of inconvenient replacement of workpieces, damage to workpieces, and low processing efficiency of workpieces, and saves the cost of loading and unloading workpieces. Time and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

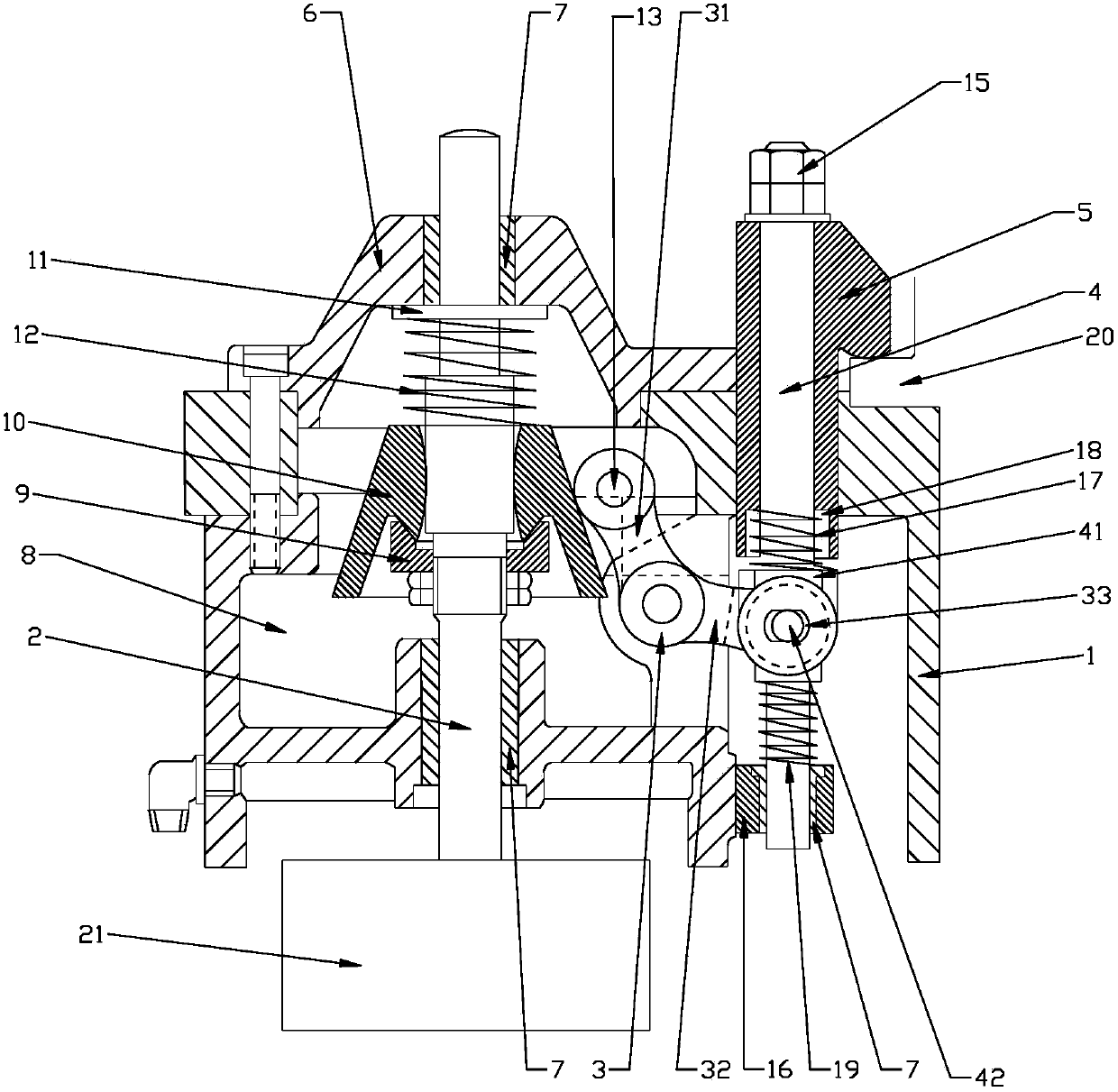

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] like figure 1 As shown, the present invention provides a flange workpiece clamping device, including a base 1, a driving rod 2, a linkage rod 3, and a pressure rod 4, wherein the base 1 is provided with a cover 6, and the cover 6 is connected to the base The seat 1 is provided with a through hole, the axes of the two through holes are consistent, the through hole is provided with a shaft sleeve 7, the driving rod 2 is slidingly fitted with the shaft sleeve 7, the lower end of the driving rod 2 is connected with a cylinder 21, and the base 1 Combined with the cover body 6 to form a structure with a cavity 8, a fixed expansion block 9 is fixedly sleeved on the drive rod 2 located in the cavity 8, and a movable expansion block 10 is provided above the fixed expansion block 9, and the movable expansion block 10 There are end faces that abut against each other with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com