3D printing personalized plunger type puncture treatment template with fixing device

A 3D printing and fixing device technology, applied in the field of medical devices, can solve the problems of inability to achieve personalized and precise treatment, inability to use bone drills, and inconsistencies in the design of needle paths, so as to reduce the learning cycle of minimally invasive treatment and the number of CT scan verifications. , The effect of reducing the cost of design and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

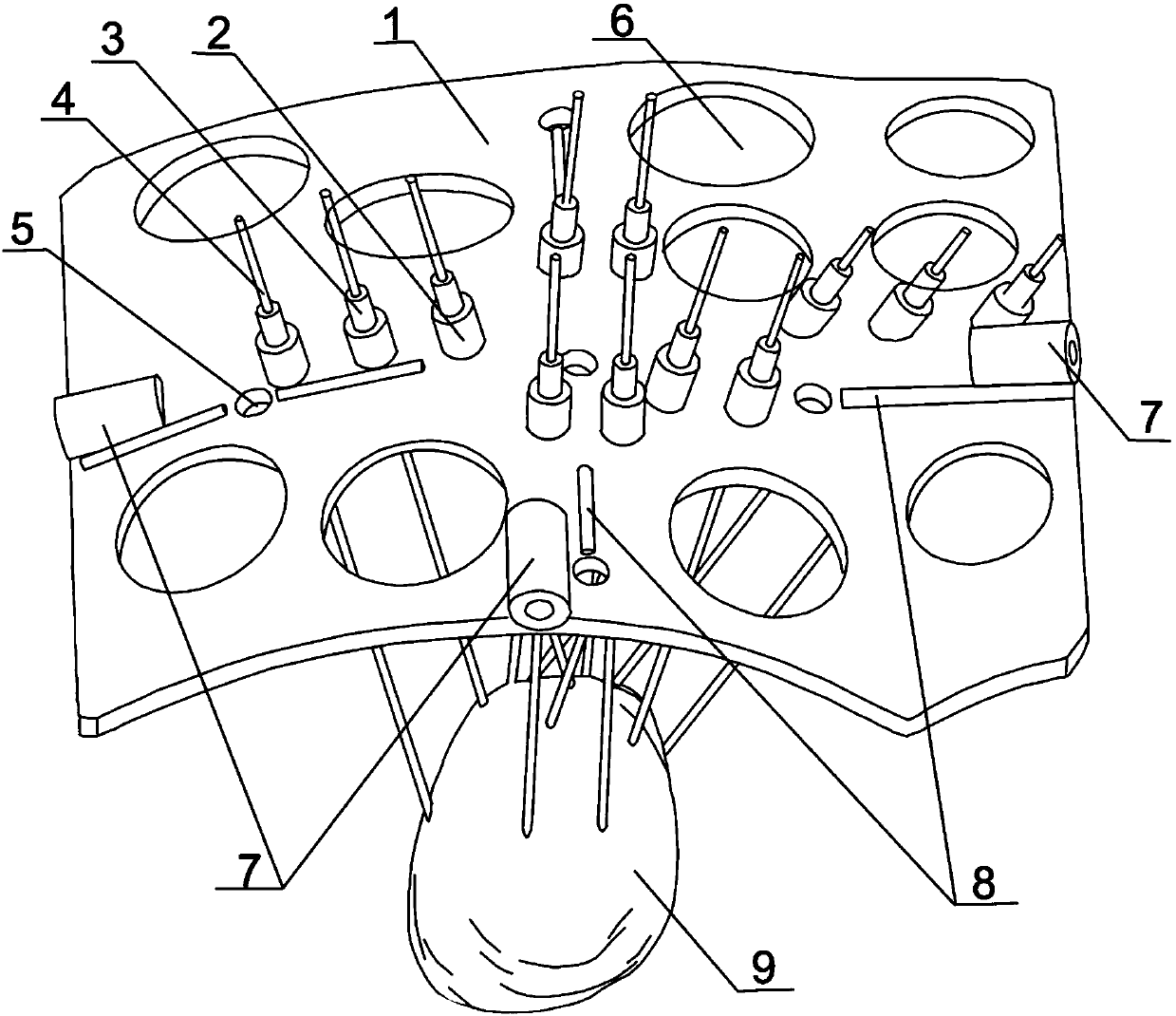

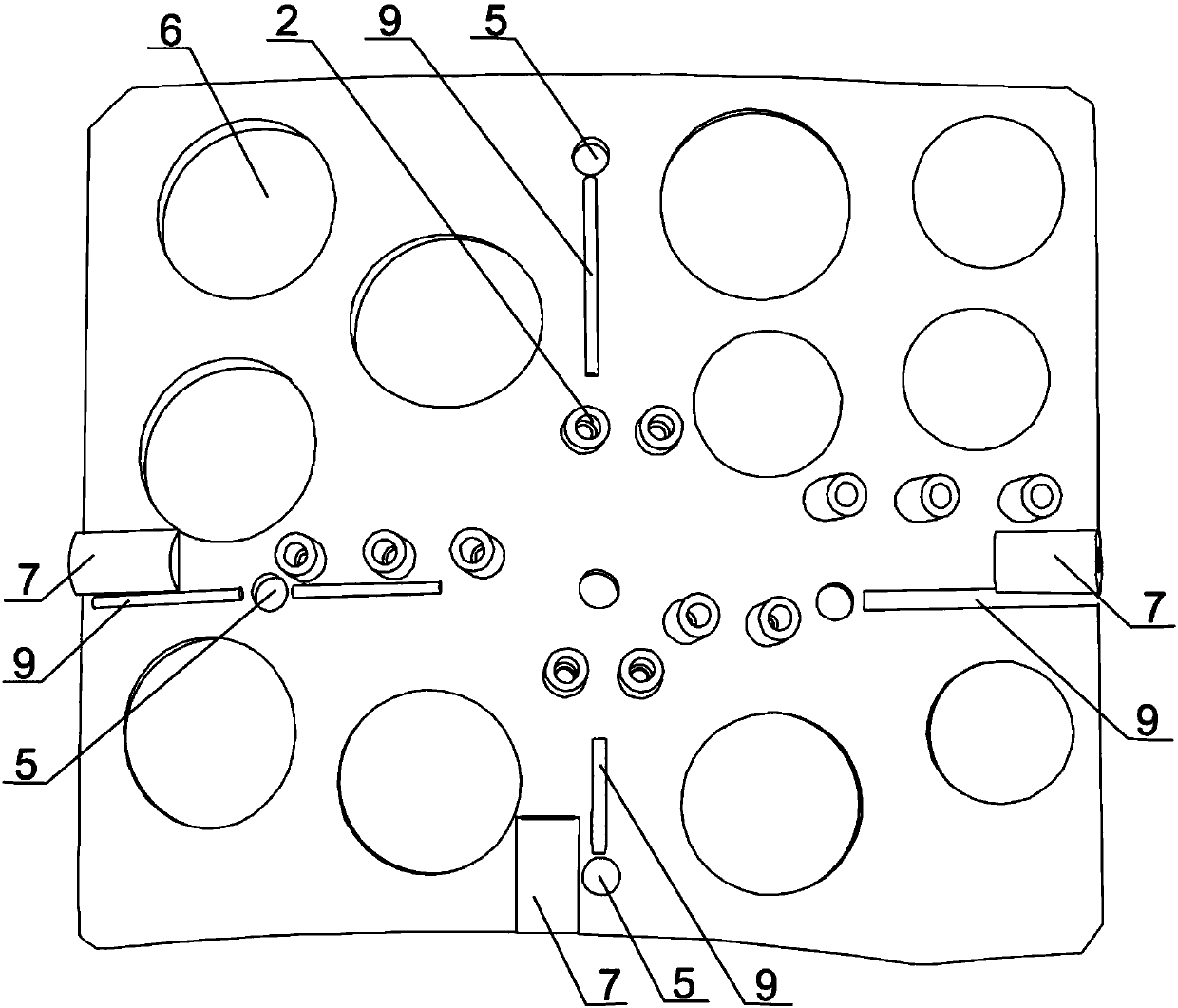

[0045] Example 1: A 3D printed personalized plunger puncture treatment (dispersed guide hole) template with a fixing device

[0046] Follow the steps below to prepare the puncture needle dispersion guide hole template:

[0047] (1) Collecting data: Scan enhanced CT of the preoperative postoperative position to obtain thin-layer CT data of the lesion area, input the CT scan data into the preoperative planning software, and formulate the puncture needle path according to the tumor size, position and the relationship between peripheral blood vessels and nerves. The number of puncture needles required is calculated and numbered, and the spatial coordinates of each puncture needle are recorded according to the number.

[0048] (2) 3D design modeling: Import CT data into 3D modeling software, reconstruct the contour of the human body surface and expand it by 3-5mm to form a template substrate. Enter the puncture needle space coordinates into the 3D modeling software according to the number...

Embodiment 2

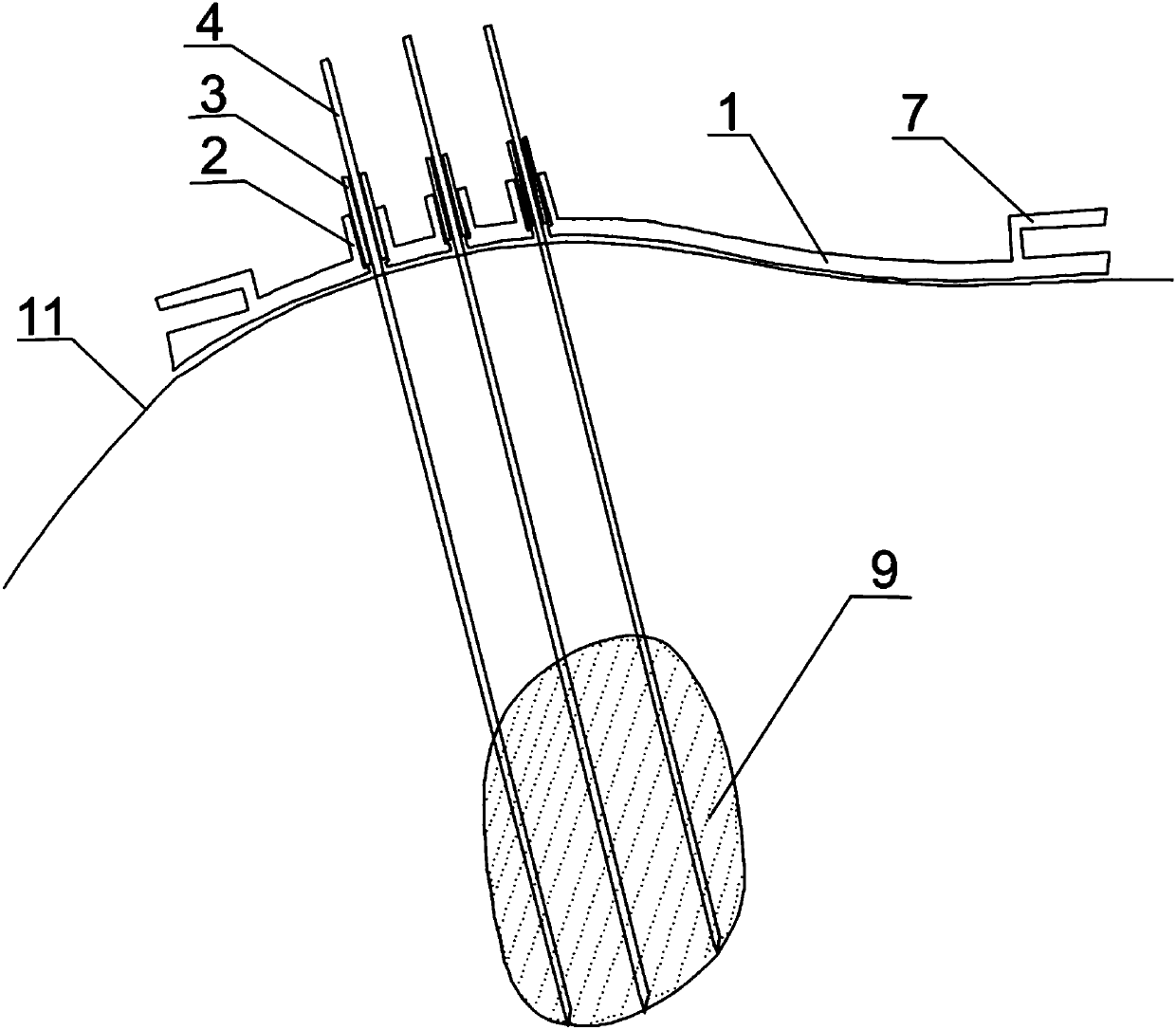

[0055] Example 2: A 3D printed personalized plunger puncture treatment (integrated guide hole) template with a fixing device.

[0056] Follow the steps below to prepare the puncture needle integrated guide hole template:

[0057] (1) Collecting data: Scan enhanced CT of the preoperative postoperative position to obtain thin-layer CT data of the lesion area, input the CT scan data into the preoperative planning software, and formulate the puncture needle path according to the tumor size, position and the relationship between peripheral blood vessels and nerves. The number of puncture needles required is calculated and numbered, and the spatial coordinates of each puncture needle are recorded according to the number.

[0058] (2) 3D design modeling: Import CT data into 3D modeling software, reconstruct the contour of the human body surface and expand it by 3-5mm to form a template substrate. Enter the puncture needle space coordinates into the 3D modeling software according to the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com