Rubber composition for hose, and hose

A technology for rubber compositions and hoses, applied in the directions of hoses, pipes/pipe joints/pipes, pipes, etc., can solve problems such as not yet obtained, and achieve the effect of ensuring flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

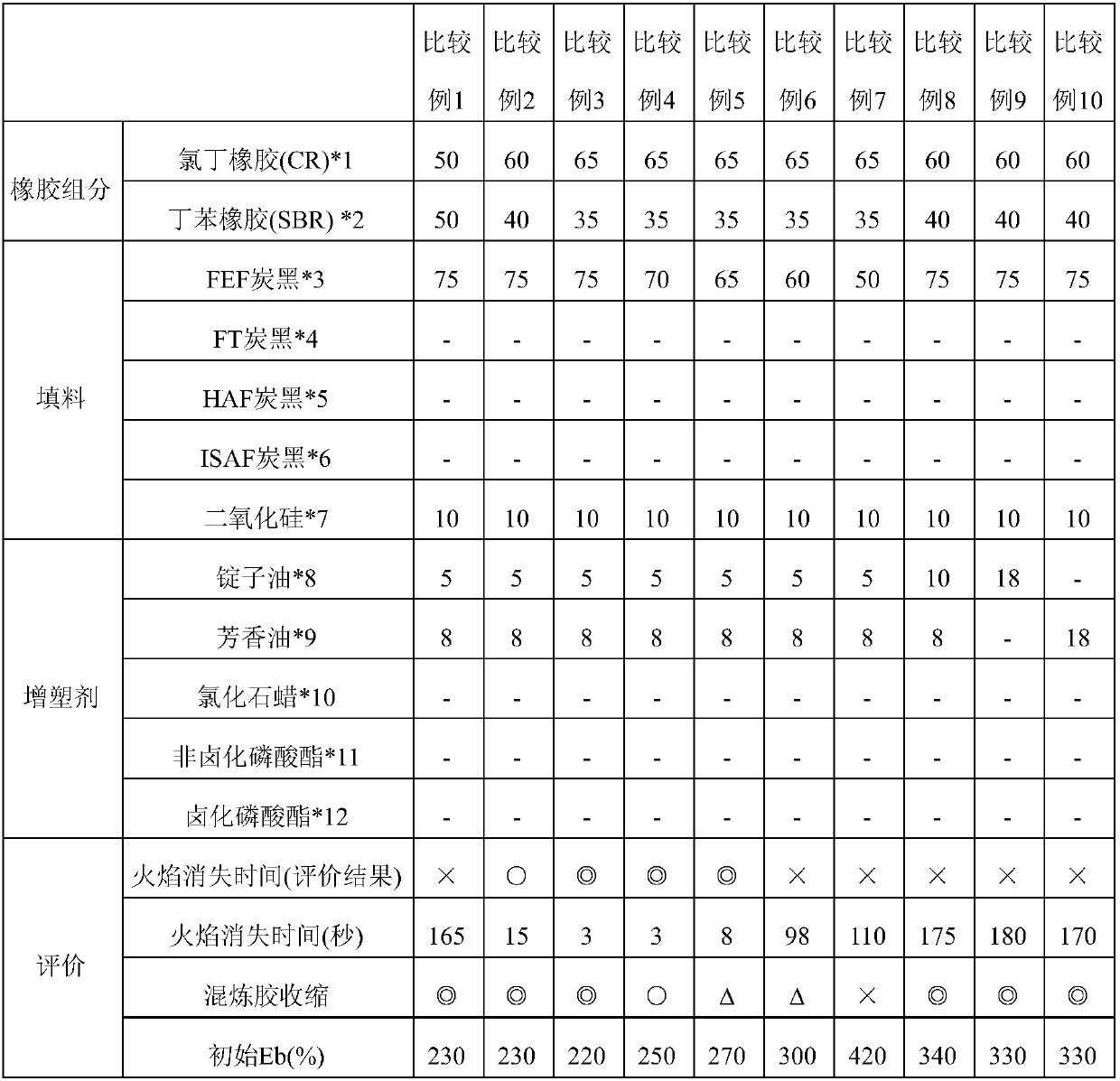

[0122] The present invention is described in more detail below by way of examples. However, the present invention is by no means limited to the following examples and appropriate changes can be made without changing the essence thereof.

[0123] The polymer and rubber compositions described below were prepared. The evaluation method of the rubber composition is as follows. The units of the values shown as compounding amounts in Tables 1 to 6 are parts by mass. In Tables 1 to 6, the rubber compositions of the respective examples and comparative examples further include (i) 5 parts by mass of zinc white (zinc oxide), (ii) 4 parts by mass of magnesium oxide, relative to 100 parts by mass of the rubber composition , (iii) 2 parts by mass of wax (OZOACE-0017, manufactured by Nippon Seiro Co., Ltd.), (iv) 3 parts by mass of antioxidant (ANTIGENE6C, manufactured by Sumitomo Chemical Co., Ltd.), (v) 2 parts by mass of cobalt stearate, (vi) 1 part by mass of sulfur, and (vii) 2 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com