Method of obtaining pressure-sensitive feedback by achieving change in the luminous flux on single optical component

A technology of luminous flux and optical components, applied in the input/output, electrical components, computer parts and other directions of user/computer interaction, which can solve the problem of inability to obtain pressing speed and pressing position, high cost of optical receivers, and discontinuous signals, etc. problems, to achieve timely and sensitive feedback, low production costs, and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

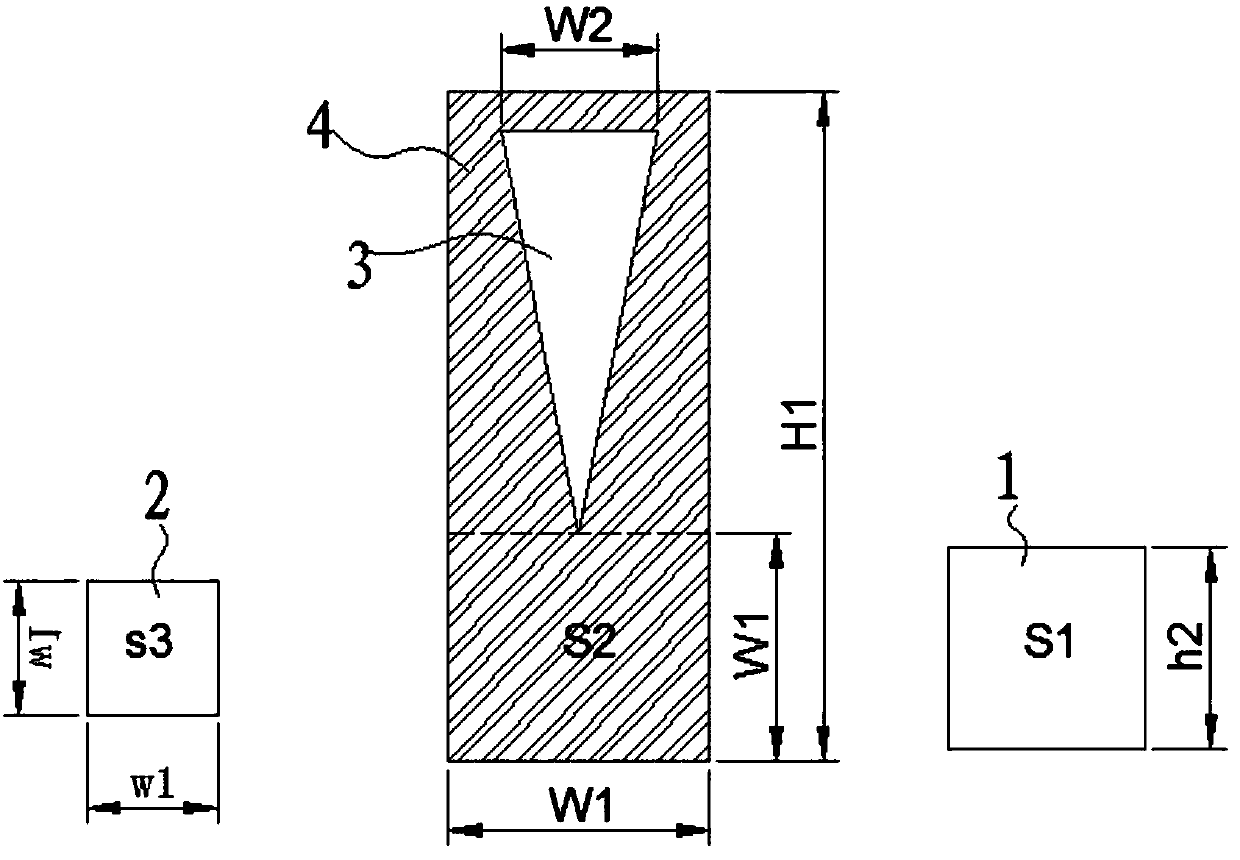

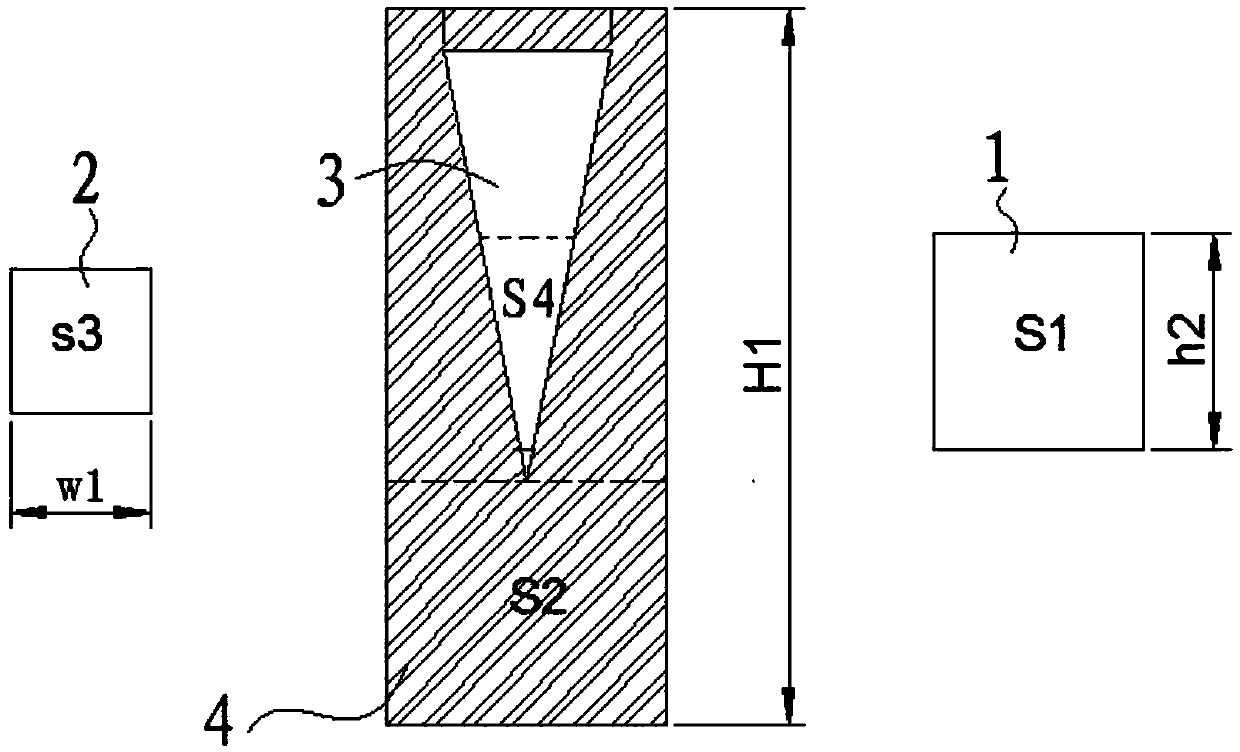

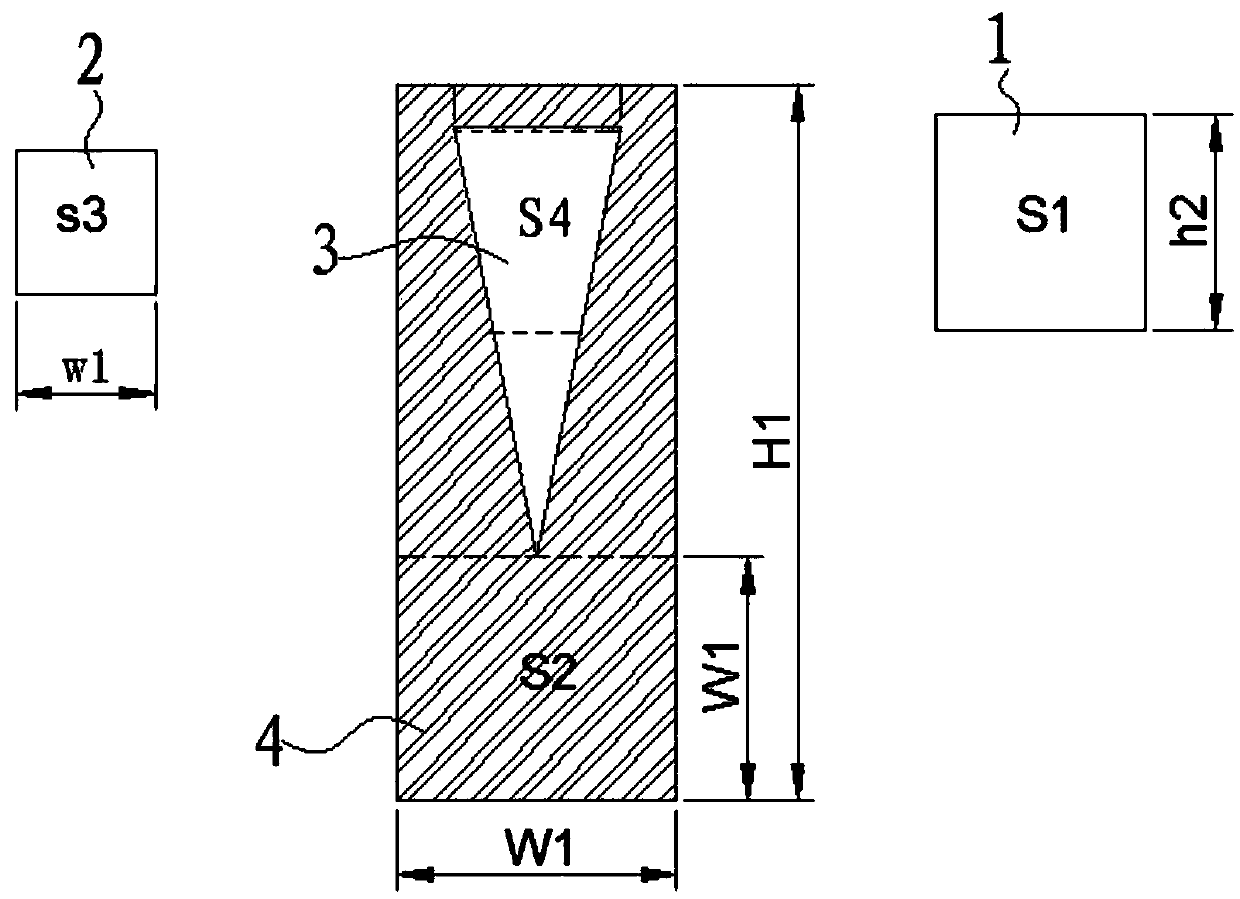

[0034] Such as Figure 1-7 As shown, the method for achieving pressure-sensitive feedback on a single light component to realize luminous flux changes includes a single light-receiving element 2 and a light-emitting element 1 that provides a light source for the light-receiving element. A switch assembly, the switch assembly includes a button part and a dimming board, the dimming board includes a base area 4 and a dimming area 3, the light transmission coefficient of the dimming area 4 is different from that of the base area 3, the dimming board Displacement occurs as the button is pressed;

[0035] Among them, the active distance of the dimmer is H1, and the height of the illuminated area of the light-emitting element is h2, where H1 is much larger than h2;

[0036] The maximum light-blocking width W1 of the dimming board, the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com