Heat dissipation and noise reduction structure of dry-wet dual-purpose motor

A wet and dry dual-purpose, noise reduction technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of motor temperature rise, dry and wet dual-purpose motor cover can not take into account noise reduction and cooling, etc., to reduce noise , Improve suction efficiency and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

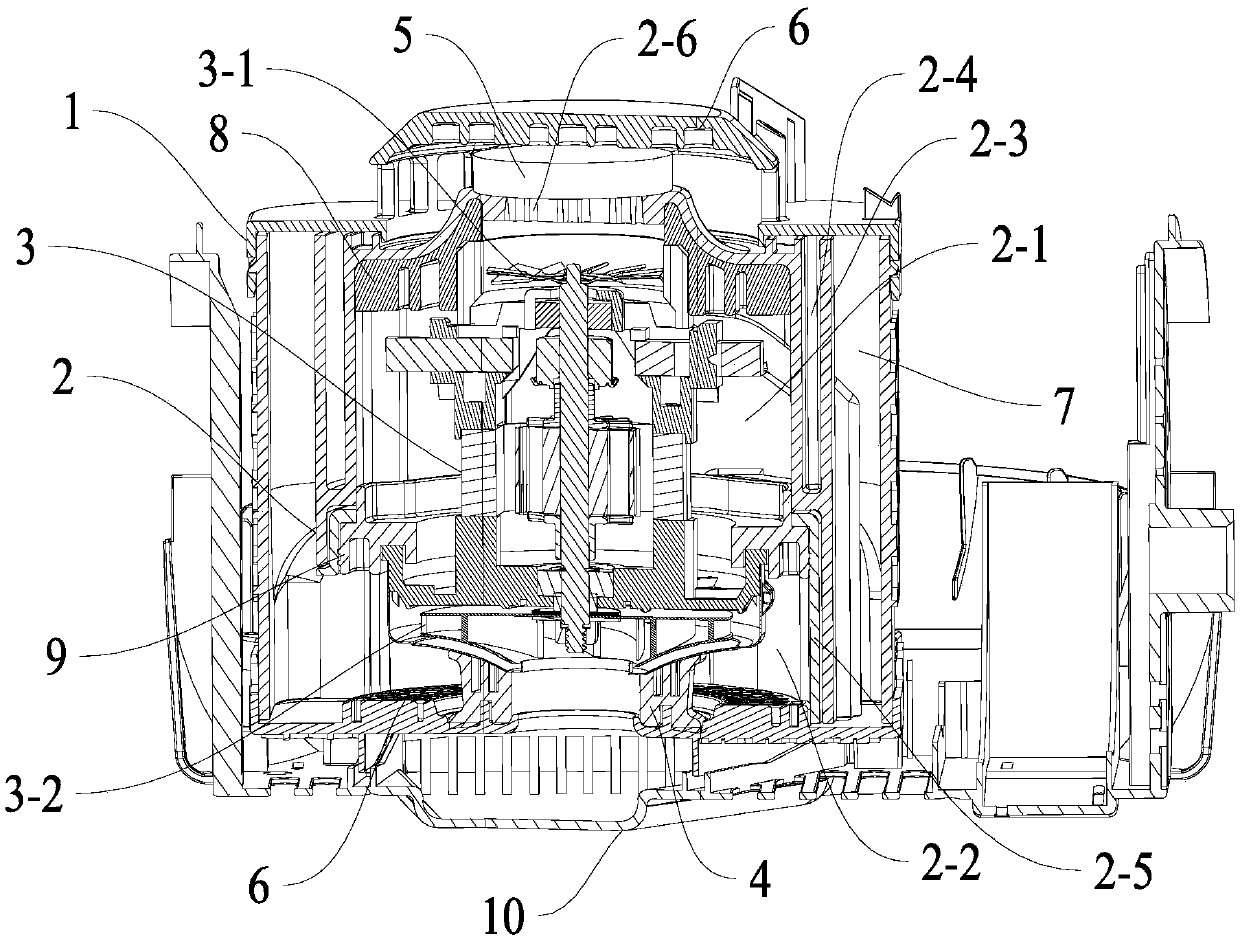

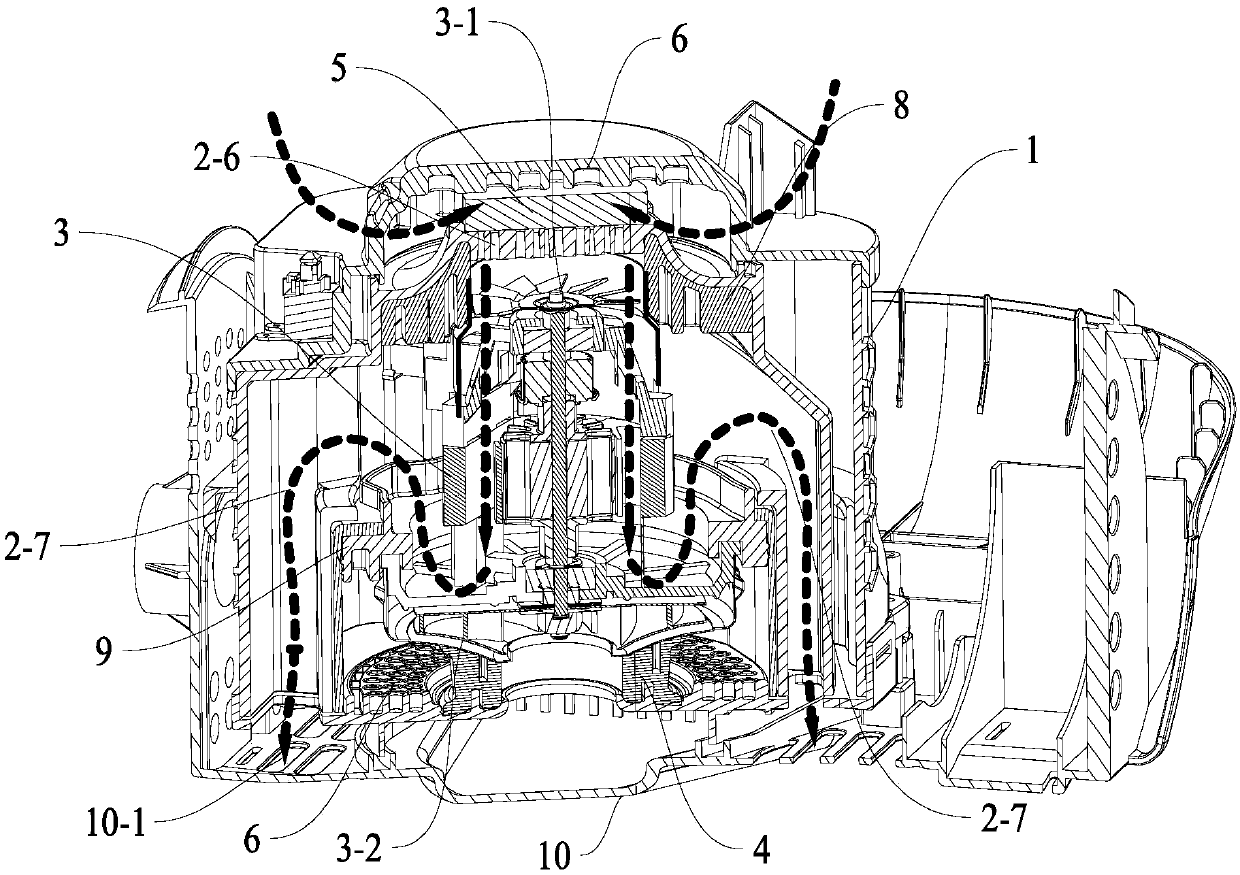

[0042] see Figure 1-2 , is a structural schematic diagram of an embodiment of the present invention, providing a heat dissipation and noise reduction structure for a wet and dry motor. The upper end of the motor 3 is provided with a heat dissipation blade 3-1, and the lower end of the motor 3 is provided with a suction blade 3-2.

[0043] The heat dissipation and noise reduction structure includes a motor cover 1, the upper end of which is provided with a cooling air inlet, the lower end is provided with a suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com