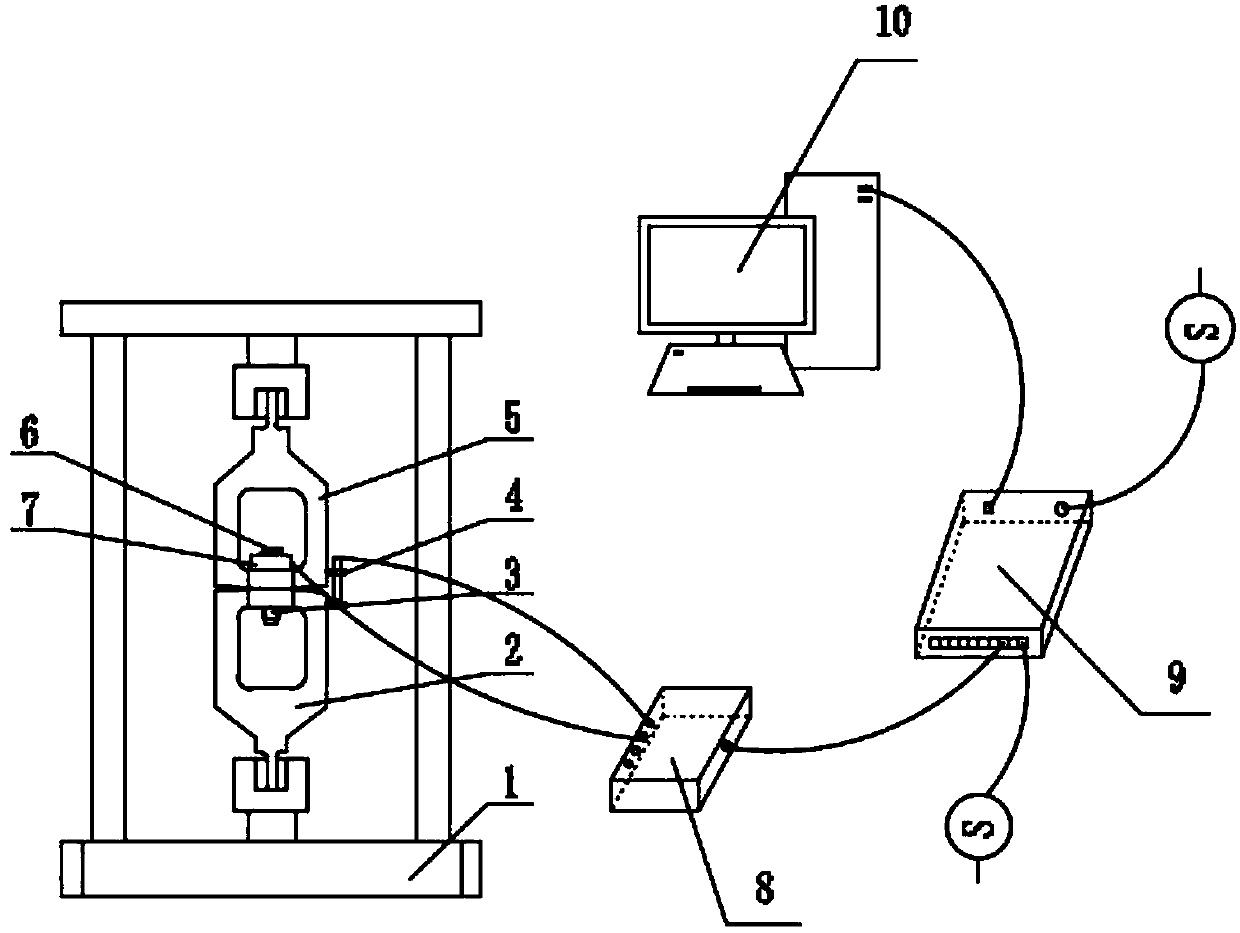

Measurement method for influence of residual stress on bolt connection structure clamping force attenuation

A technology of residual stress and connection structure, applied in force/torque/work measuring instruments, using stable tension/pressure to test material strength, measuring devices, etc., can solve complex operations, low measurement accuracy, and inability to quantitatively analyze residual Problems such as the relationship between stress and bolt clamping force, to achieve accurate experimental results, accurate data, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

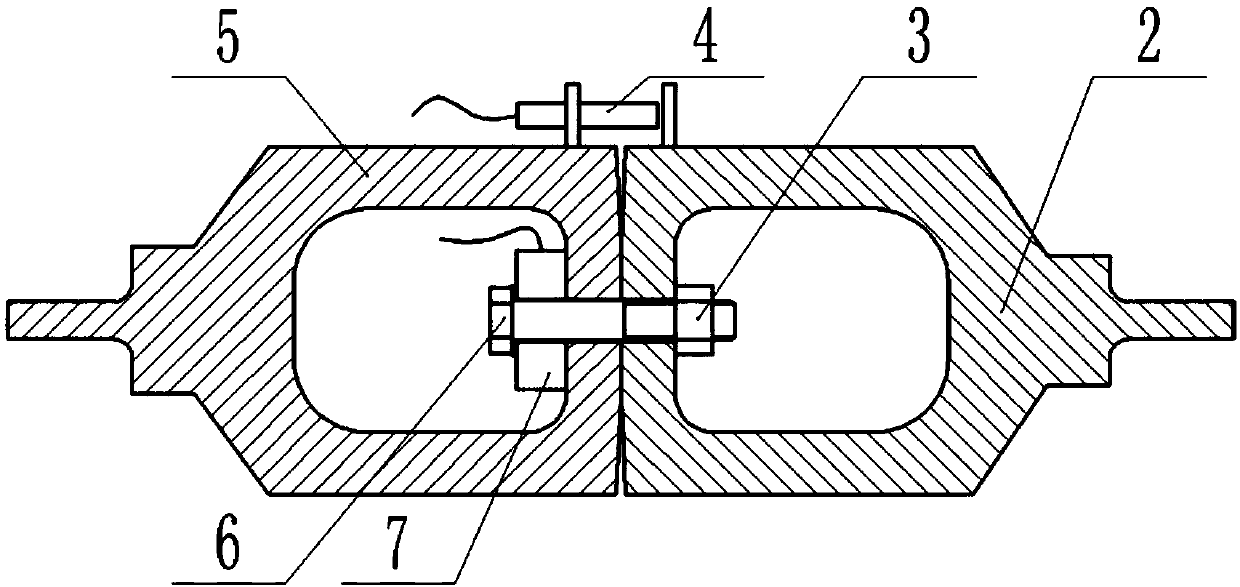

[0022] Step 1: Divide N bolt fasteners of the same batch and the same material into M groups, with n pieces in each group, numbered Ⅰ, Ⅱ, Ⅲ, ..., and the corresponding axial connectors are numbered 1, 2 in sequence , ..., and ultrasonically cleaned them before the experiment.

[0023] Step 2: Apply a certain amplitude of exciting force and continuous vibration of frequency to the M group of bolts fixed on the vibrating table. At the same time interval, remove a group of bolts in sequence until all the bolts are removed.

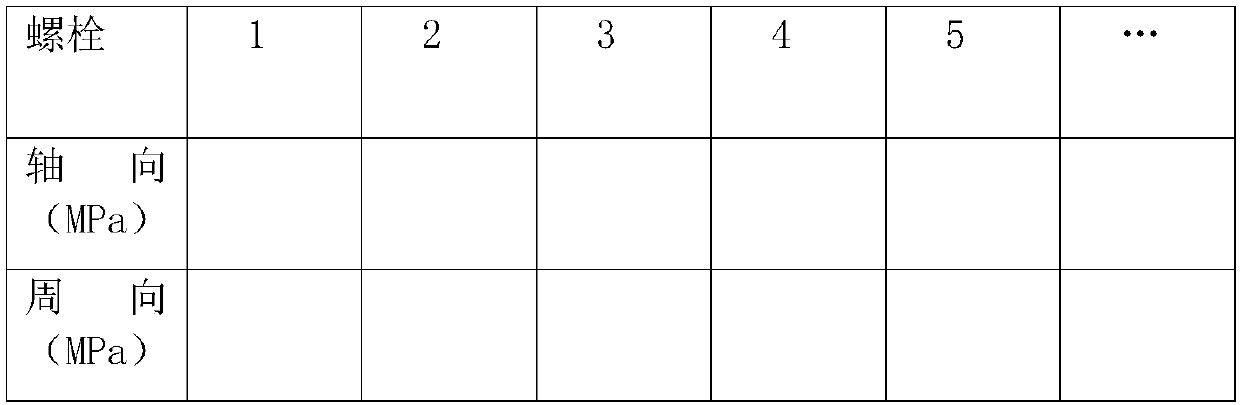

[0024] Step 3: Set aside the experimental bolts of group M after vibration to release the residual stress in the experimental bolts. Then select 3 to 5 test points on the polished rod of each bolt in each group of experimental bolts, carry out the residual stress test through the X-ray residual stress tester, measure the residual stress in the circumferential and axial directions of each measuring point, and record, such as figure 2 shown.

[0025] Step 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com