Air pressure measuring device and air pressure measuring method

An air pressure and measurement technology, which is applied in the direction of measuring device, elastic deformation gauge fluid pressure measurement, fluid pressure measurement, etc., can solve the problems of output saturation, film damage, large film deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

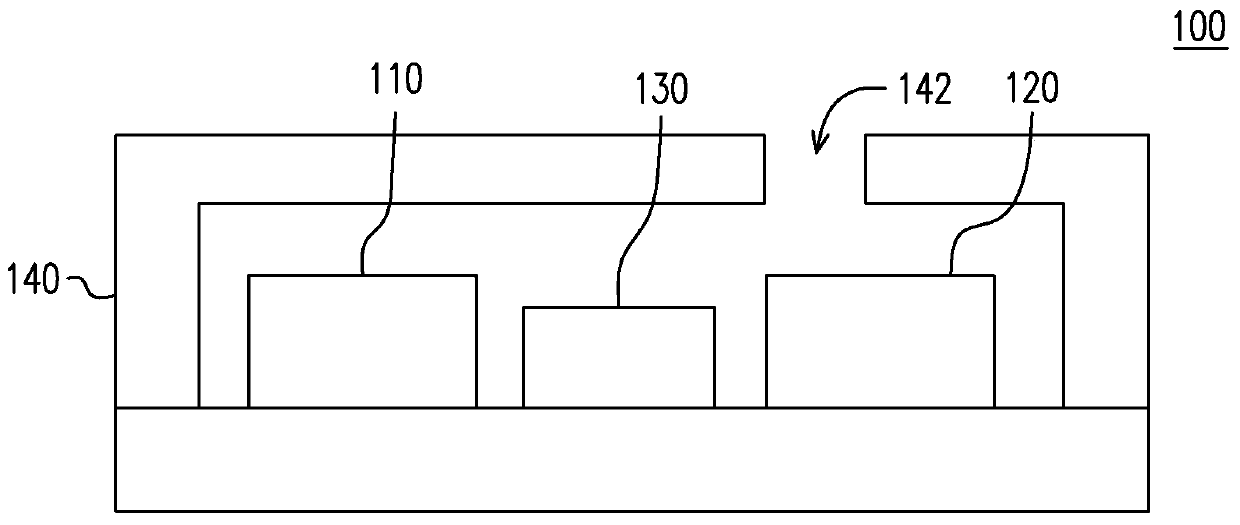

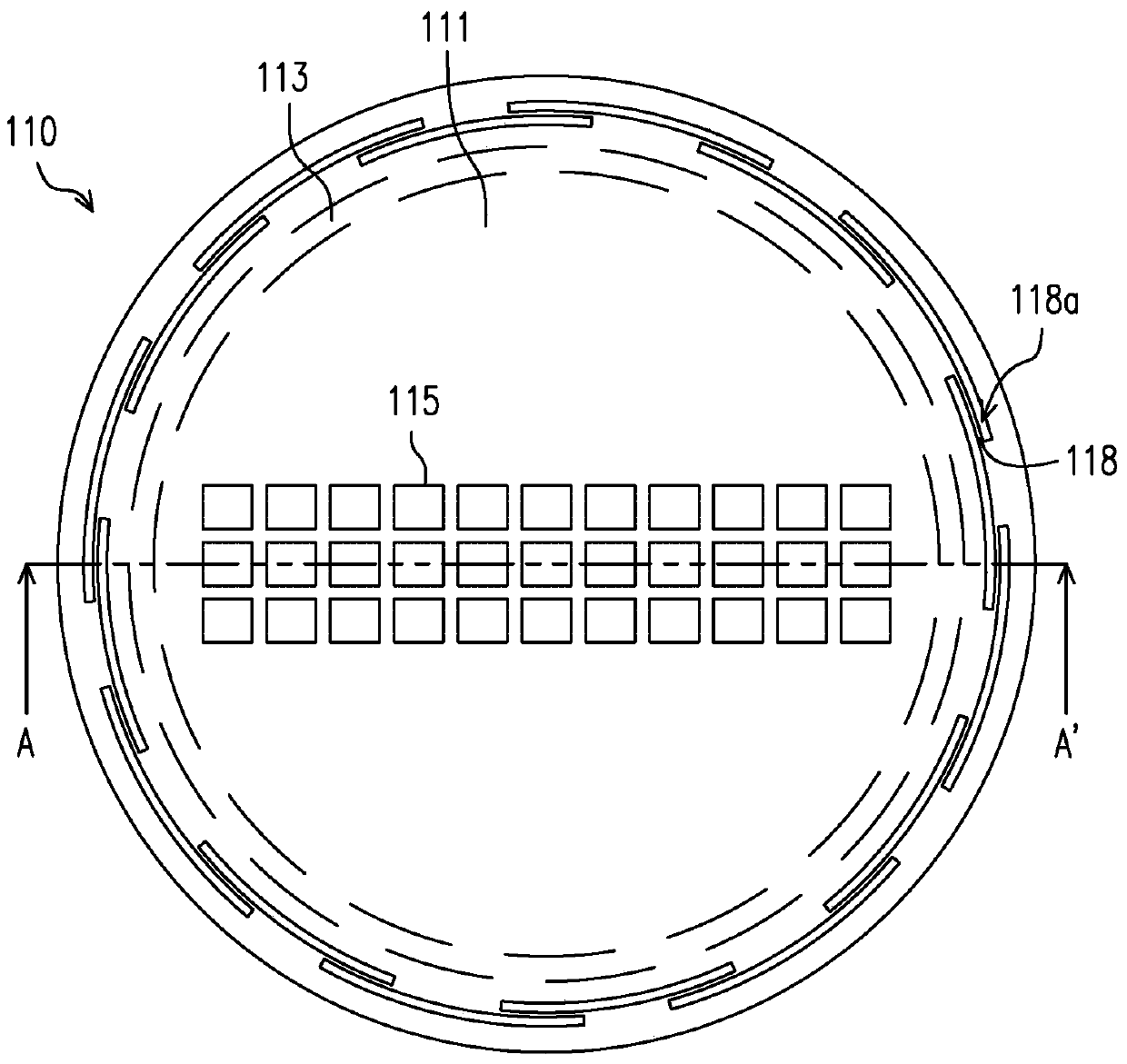

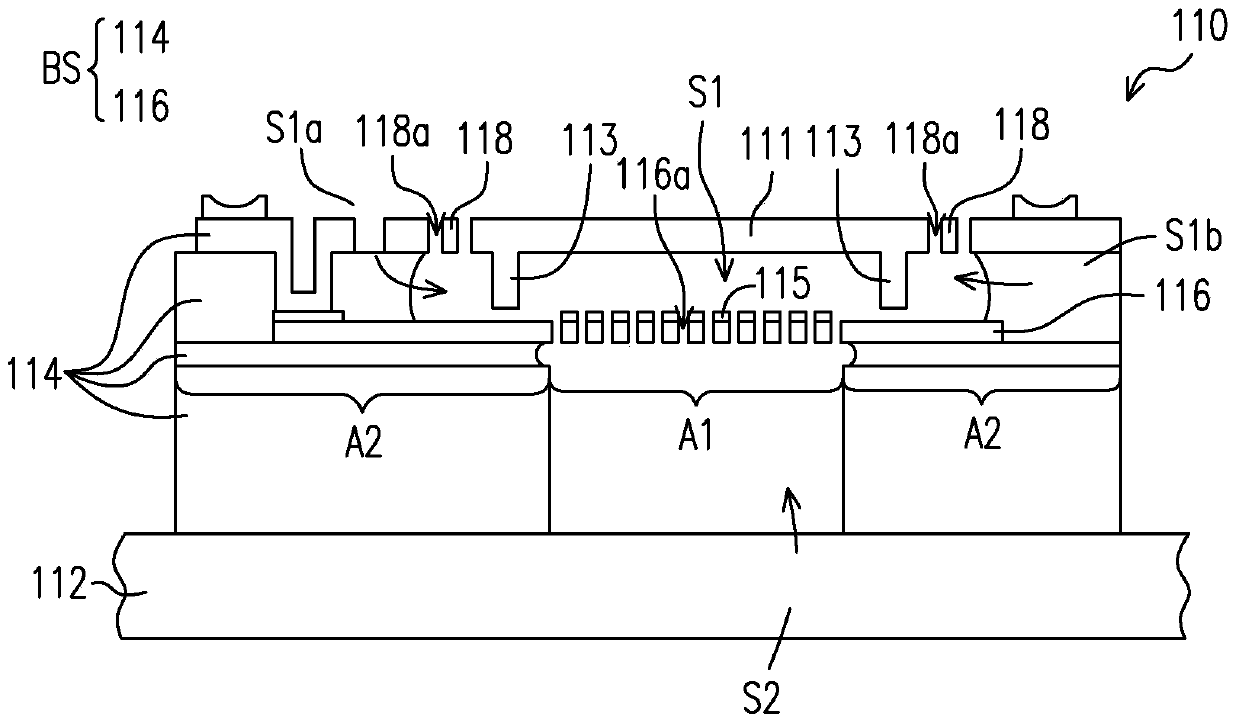

[0076] Embodiment one: see attached Figure 1-4 As shown, in this embodiment, the air pressure measurement device 100 includes a housing 140 and a first sensing unit 110, a second sensing unit 120 and a control module 130 disposed in the housing, wherein the control module 130 includes a special application A functional module composed of an integrated circuit (Application-specific integrated circuit, ASIC) or other components with similar functions is electrically connected to the first sensing unit 110 and the second sensing unit 120 . The first sensing unit 110 may be a capacitive pressure sensor made with MEMS technology, and the second sensing unit 120 may be a piezoresistive pressure sensor.

[0077] In this embodiment, the measurement accuracy of the first sensing unit 110 is greater than the measurement accuracy of the second sensing unit 120 , and the measurement range of the second sensing unit 120 is greater than the measurement range of the first sensing unit 110 ...

Embodiment 2

[0088] Embodiment two: see attached Figure 8-9 As shown, the present embodiment is basically the same as the first embodiment, except that in the first sensing unit 210 of the present embodiment, the support member 213 is integrated with the semiconductor layer 216 of the semiconductor layer structure.

[0089] Further, the first sensing unit 210 is adapted to be disposed on the circuit substrate 212 , and the first sensing unit 210 includes a semiconductor layer structure (including a plurality of semiconductor layers 214 and 216 ), a thin film 211 and an elastic member 218 . Similar to the foregoing embodiments, the semiconductor layer structure has a cavity, and the film 211 is connected to the semiconductor layer 214 via an elastic member 218 to be movably suspended in the cavity, and the semiconductor layer 216 is provided with a plurality of electrodes 215 facing the film 211, And with the control module 130 (as attached figure 1 , attached Image 6 shown, omitted in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com