A kind of curved screen all-inclusive soft film and preparation method thereof

A technology of curved screen and soft film, which is applied in the field of curved screen all-inclusive soft film and its preparation, which can solve the problems of poor adhesion and bonding effect of curved screen film, increased cost of curved screen film, high price of TPU, etc., and achieves good adhesion. Combined effect, solve the difficulty of tearing the film, and the effect of stable dirt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

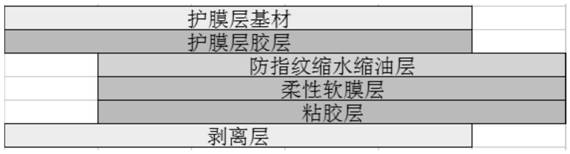

[0049] The present invention also provides a method for preparing the curved screen all-encompassing soft film described in the above technical solution, comprising the following steps:

[0050] a) coating a layer of flexible polyurethane modified silicone resin on the carrier film, and curing for the first time to obtain a flexible soft film layer;

[0051] b) compound the adhesive layer on the surface of the flexible soft film layer obtained in step a), and then compound the peeling layer on the surface of the adhesive layer, then tear off the carrier film on the flexible soft film layer, and place it on the flexible soft film The anti-fingerprint shrinkage oil layer is compounded on the surface of the layer to obtain a use layer compounded with a peeling layer;

[0052] c) composite the protective film layer adhesive layer on the protective film layer base material to obtain the protective film layer, and finally combine the protective film layer adhesive layer in the prote...

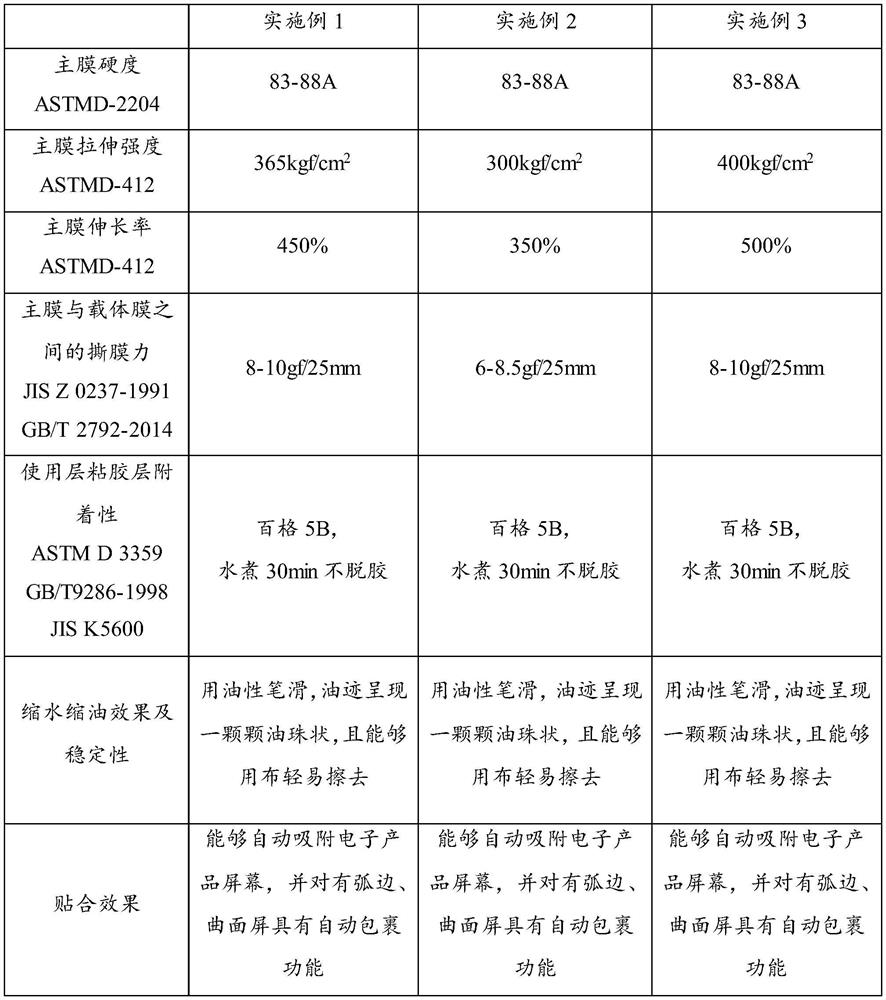

Embodiment 1

[0074] (1) Coat a layer of flexible polyurethane modified silicone resin on the carrier film, bake at 120°C for 60s, and after curing, obtain a flexible soft film layer (main film) with a dry thickness of 125 μm;

[0075] (2) Coat a layer of silicone pressure-sensitive adhesive resin on the surface of the flexible soft film layer (main film) obtained in step (1), bake at 150°C for 75s, and after curing, obtain an adhesive layer with a dry thickness of 45 μm ; Afterwards, a layer of 8gf / 25mm fluoroplastic PET release film is covered on the surface of the adhesive layer to obtain a peeling layer with a thickness of 50 μm;

[0076] (3) Tear off the carrier film on the flexible soft film layer (main film), and coat a layer of silicone oil release agent on the surface of the flexible soft film layer (main film), bake at 90°C for 45s, and cure Finally, the anti-fingerprint shrinkage shrinkage oil layer with a dry thickness of 600nm is obtained, thereby obtaining a use layer compound...

Embodiment 2

[0079] (1) Coat a layer of flexible polyurethane modified silicone resin on the carrier film, bake at 100°C for 60s, and after curing, obtain a flexible soft film layer (main film) with a dry thickness of 100 μm;

[0080] (2) Coat a layer of silicone pressure-sensitive adhesive resin on the surface of the flexible soft film layer (main film) obtained in step (1), bake at 150°C for 60s, and after curing, obtain an adhesive layer with a dry thickness of 30 μm ; Afterwards, a layer of 8gf / 25mm fluoroplastic PET release film is covered on the surface of the adhesive layer to obtain a peeling layer with a thickness of 50 μm;

[0081] (3) Tear off the carrier film on the flexible soft film layer (main film), and coat a layer of silicone oil release agent on the surface of the flexible soft film layer (main film), bake at 90°C for 45s, and cure Finally, the anti-fingerprint shrinkage shrinkage oil layer with a dry thickness of 1000nm is obtained, thereby obtaining a use layer compoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com