Sewage treatment process with convenient automatic operation

A technology for sewage treatment and automatic operation, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc., and can solve the problem of inconvenient bottom sludge replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

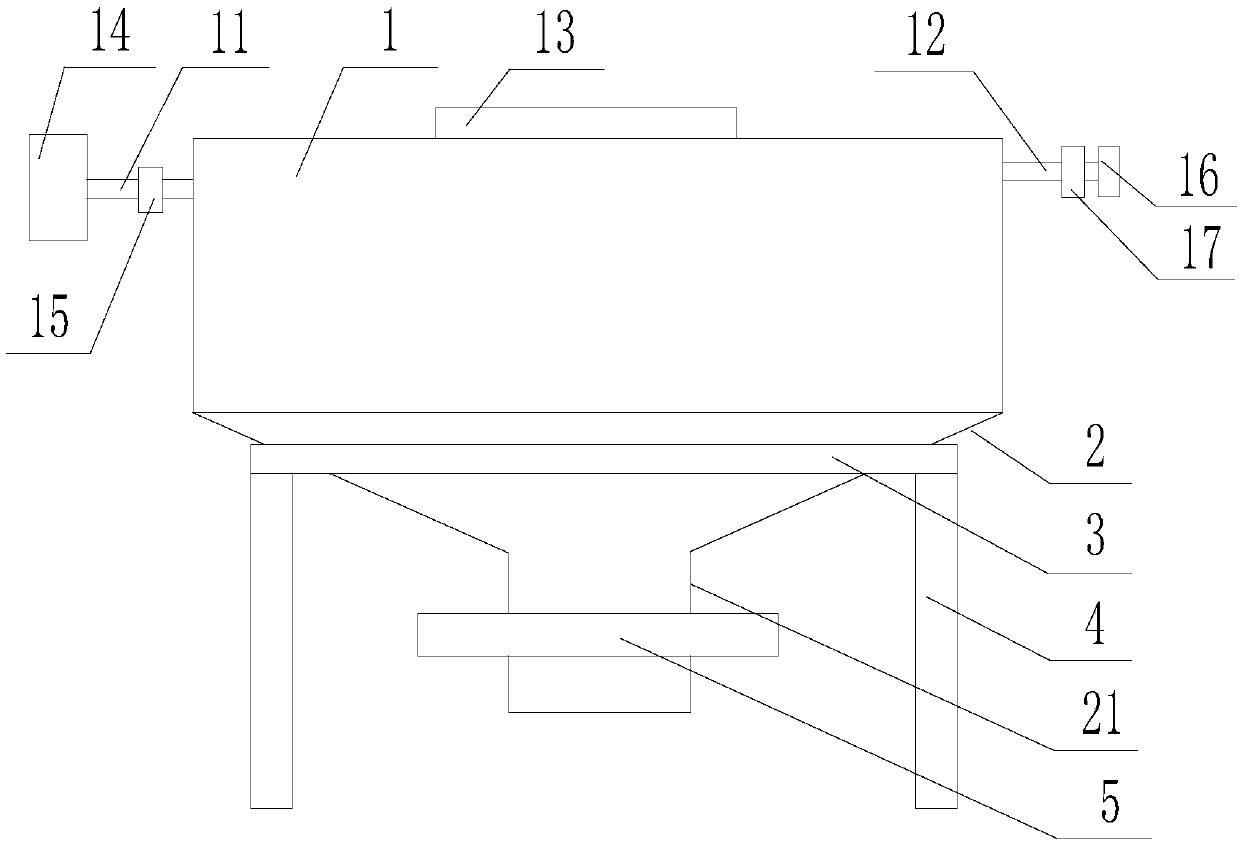

[0037] Such as figure 1 As shown, the sewage treatment process that is convenient for automatic operation includes the following steps:

[0038] 1) Centralized collection of sewage;

[0039] 2) transporting the sewage collected in step 1) to the sedimentation tank for sewage precipitation;

[0040] 3), transporting the settled sewage in step 2) to the sludge tank for organic matter treatment,

[0041] 4), transporting the sewage treated in step 3) to the membrane tank for membrane filtration treatment;

[0042] 5) Discharge after passing the water quality test;

[0043] Described settling tank comprises tank body 1, and described tank body 1 is provided with inlet pipe 11 and outlet pipe 12, and described inlet pipe 11 is provided with inlet valve 15, and described outlet pipe 12 is provided with outlet valve 16, The bottom of the tank body 1 is provided with sludge, and the bottom of the tank body 1 is sunken downward to form an arc-shaped groove 2, and the bottom of the ...

Embodiment 2

[0045] Such as figure 1 As shown, this embodiment is based on Embodiment 1, the top of the tank body 1 is provided with a dosing tube 13; the tank body 1 is arranged in an annular support body 3 supported by three legs 4 The mud discharge pipe 21 is suspended in the air; the water inlet pipe 11 is provided with a filter 14 at the front end of the water inlet valve 15; the outlet pipe 12 is provided with a sewage online detector 17 at the front end of the water outlet valve 16.

[0046] Example 2:

[0047] The present embodiment is based on embodiment 1 or embodiment 2, in step 1) adds sewage treatment agent, and described sewage treatment agent is made up of following components by weight:

[0048] 30 parts by weight of polyacrylamide, 15 parts by weight of basic aluminum chloride, 10 parts by weight of ferric oxide, 25 parts by weight of calcium oxide, and 15 parts by weight of bentonite.

[0049] In this embodiment, the polyacrylamide described in the present invention has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com