Base plate assembly and digital printing apparatus

A digital printing and bottom plate technology, applied in printing, transfer materials, power transmission devices, etc., can solve the problems of reducing the quality of printed products and inconsistency in height, and achieve the effect of making up for the lack of processing accuracy and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

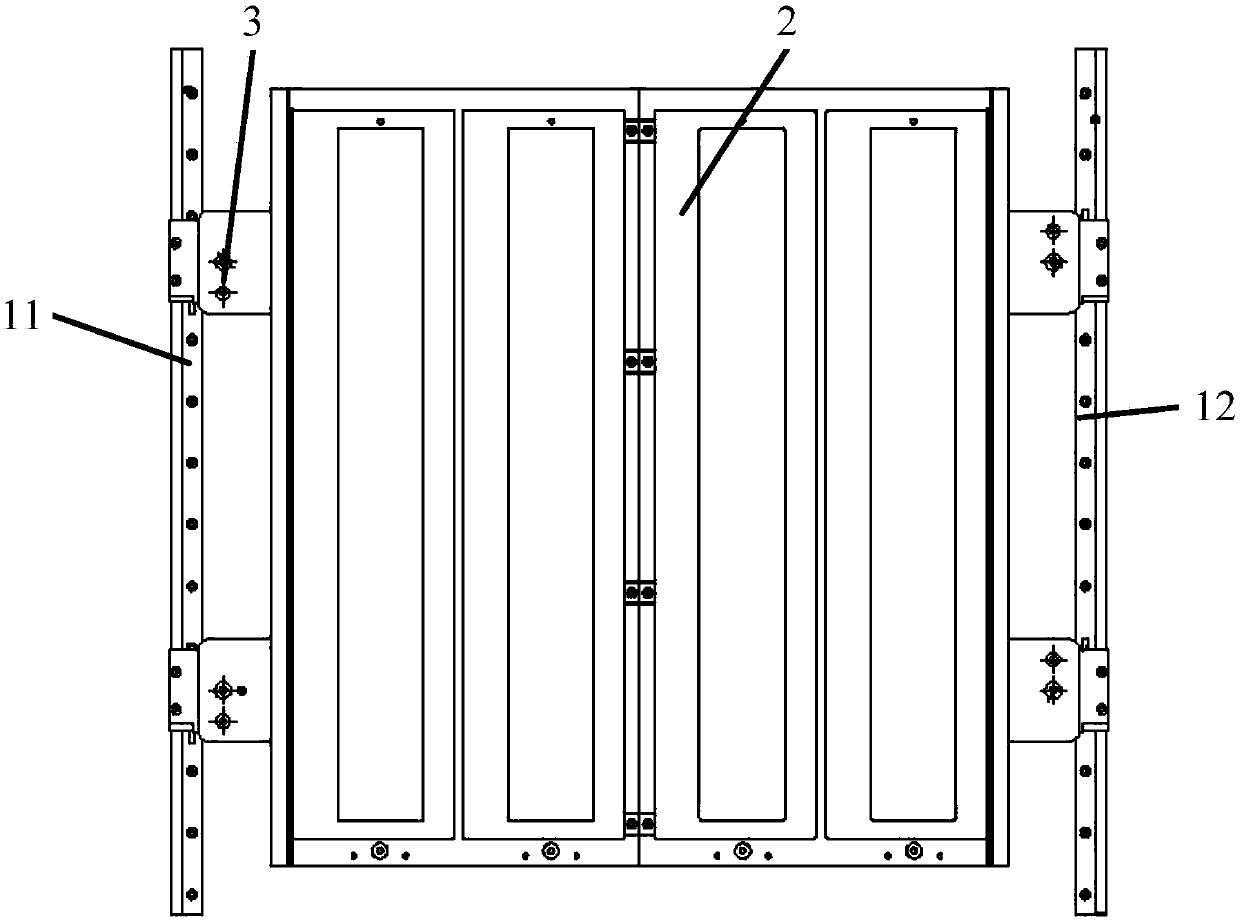

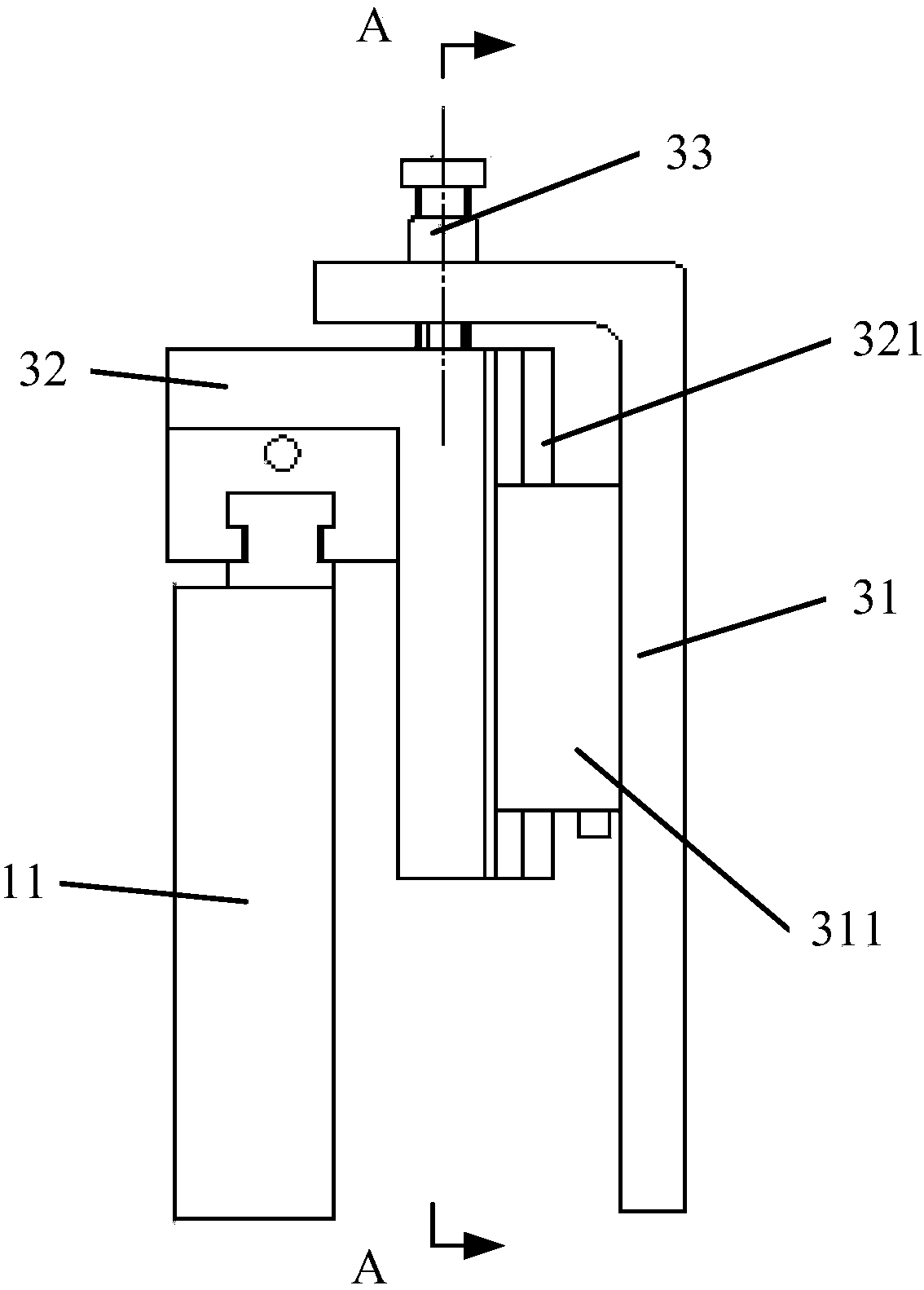

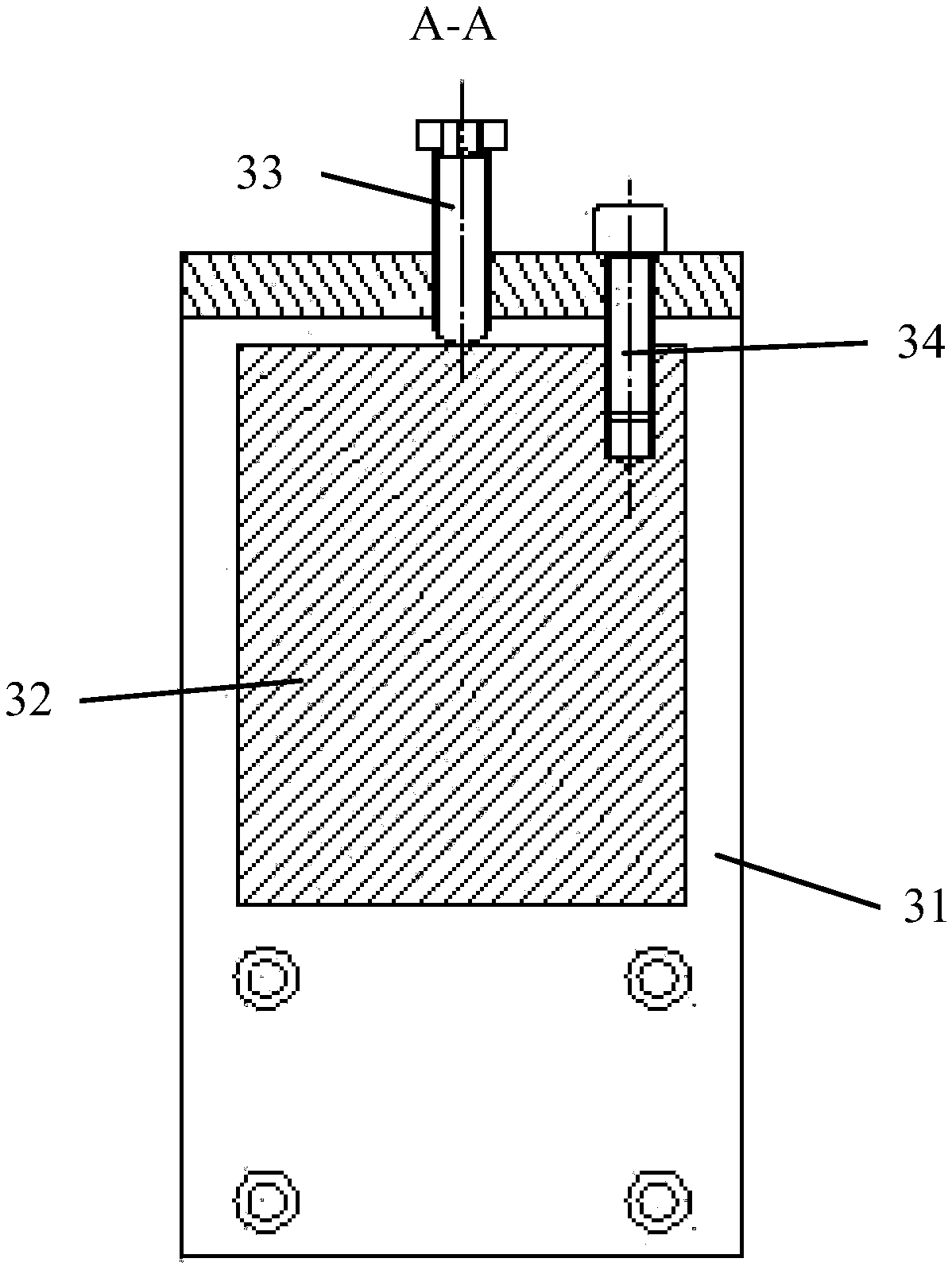

[0039] Such as figure 1 As shown, the present invention provides a bottom plate assembly for digital printing equipment, the digital printing equipment includes a substrate, wherein the bottom plate assembly includes: slide rails, the slide rails include a first slide rail 11 and a second slide rail 12; the bottom plate 2. One end of the base plate 2 is connected to the first slide rail 11, and the other end of the base plate 2 is connected to the second slide rail 12; the adjustment assembly 3 is installed on the slide rail and connected to the base plate 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com