Crystal haw jelly slicing machine

A hawthorn cake and slicer technology, applied in metal processing, etc., can solve the problems of different product sizes, unfavorable packaging, and low production efficiency, and achieve the effects of precise cutting, reduced power loss, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

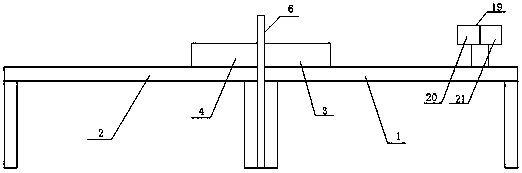

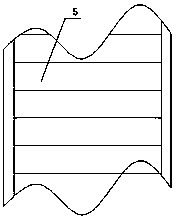

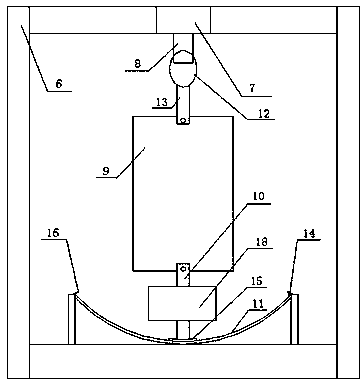

[0029] Put the hawthorn cake to be sliced on the feeding table 1, adjust the crawler belt 5 and the movement speed and the movement speed of the push rod 14 through the crawler regulator 20 and the push rod regulator 21, such as advancing 10cm each time, pausing for 1s, cutting knife 9 Complete the slicing of hawthorn jelly within 1s. The positioning box 3 and the receiving box 2 are respectively connected to the feeding platform 1 and the receiving platform 2. The positioning box 3 and the receiving box 2 can be respectively connected to the feeding platform 1 and the receiving platform through screws. Table 2 is movably connected, and the positioning box 3 and the object box 2 are adjusted according to the shape of the product. They are mainly used for positioning protection when slicing haw jelly to prevent movement. The power block 18 increases the cutting knife. Power potential energy, the lower connecting rod 10 adopts the setting of magnetic levitation to reduce the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com