Nut end surface grinding equipment

An end face and nut technology, which is applied in the field of nut end face grinding equipment, can solve the problems of low grinding efficiency, high labor intensity, and easy injury to workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

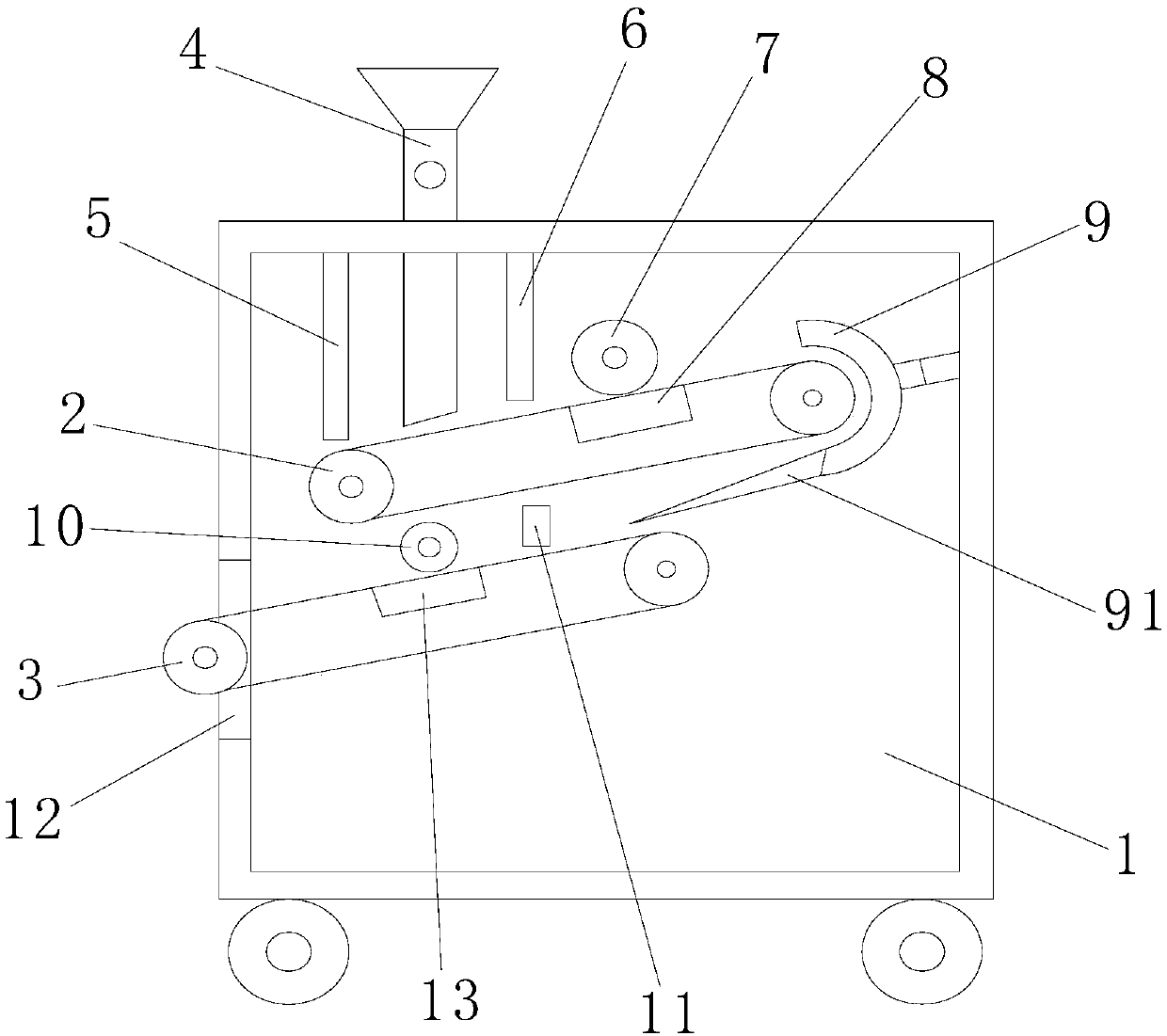

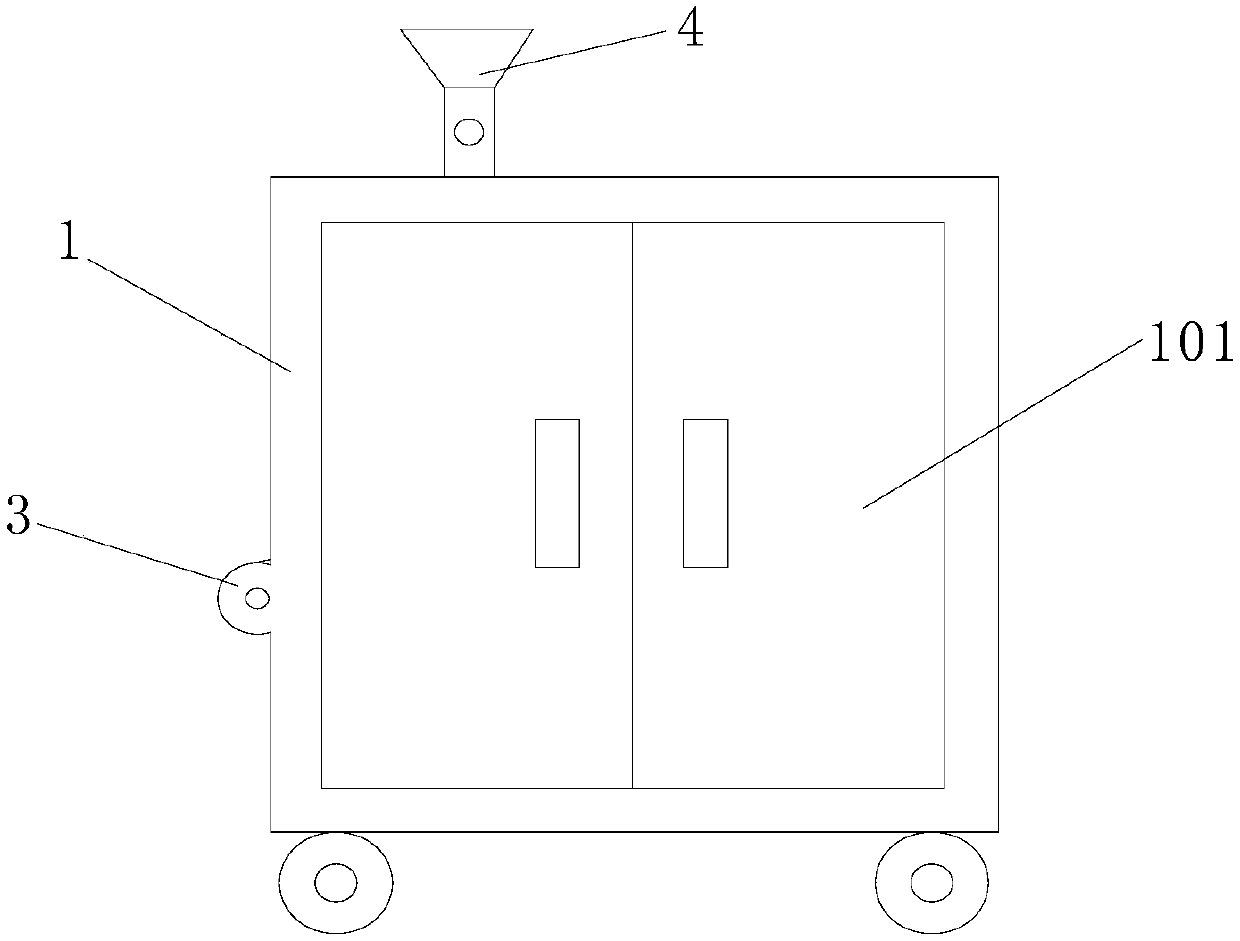

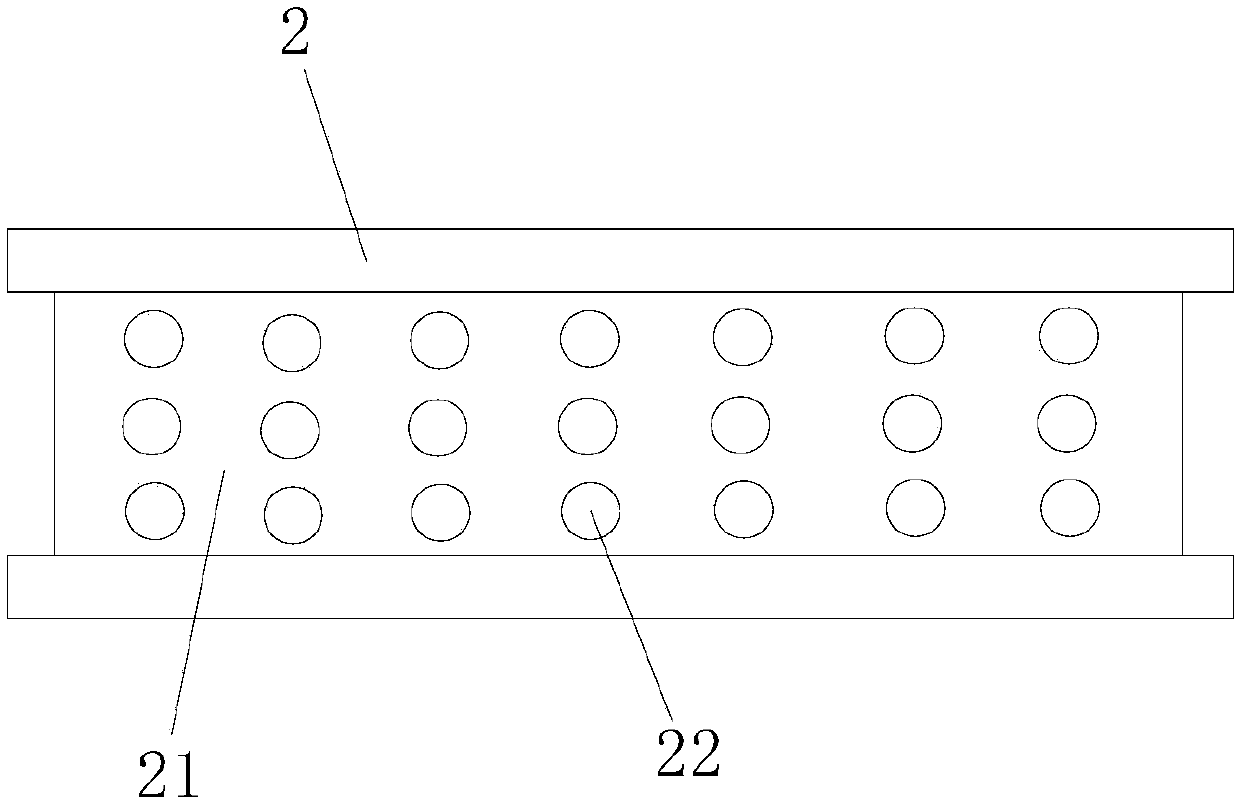

[0018] refer to figure 1 , 2 , 3, a kind of nut end face grinding equipment of the present invention, comprises chassis 1, upper conveyer belt 2, lower conveyer belt 3, lower hopper 4, baffle plate 5, first fence 6, first grinding roller 7, first magnet block 8, Turn over baffle plate 9, the second grinding roller 10, the second fence 11, the discharge port 12 and the second magnet block 13, the upper conveyor belt 2 with the output end upturned is provided in the said cabinet 1, the upper conveyor belt 2 The belt surface is provided with an annular groove 21 along the length direction, and the groove bottom of the annular groove 21 is provided with a number of evenly distributed accommodation grooves 22 for accommodating nuts, and the input box 1 is located directly below the upper conveyor belt 2 in the cabinet 1. A lower conveyor belt 3 with an upturned end, the structure of the lower conveyor belt 3 is exactly the same as that of the upper conveyor belt 2, the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com