Method and device for realizing arbitrary fixed-length of steel rail

A technology of steel rail and sizing, applied in the field of rail rolling, can solve the problems of long time required, difficult sizing work, inconvenient adjustment of sizing specifications, etc., and achieves the effect of high sizing accuracy and convenient replacement of sizing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

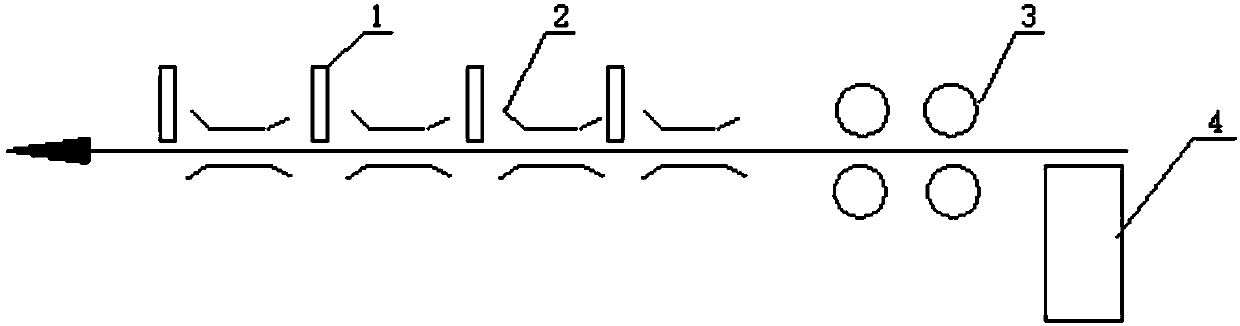

[0034] 1) Taking the sawing machine 4 as the starting point, according to the fixed-length setting value on the rear track of the sawing machine 4, 26 meters (the fixed-length setting value is 25 meters), 51 meters (the fixed-length setting value is 50 meters) and 51 meters away from the sawing machine 4 sets of liftable laser range finders 1 are installed at 76 meters (the fixed-length setting value is 75 meters) and 101 meters (the fixed-length setting value is 100 meters).

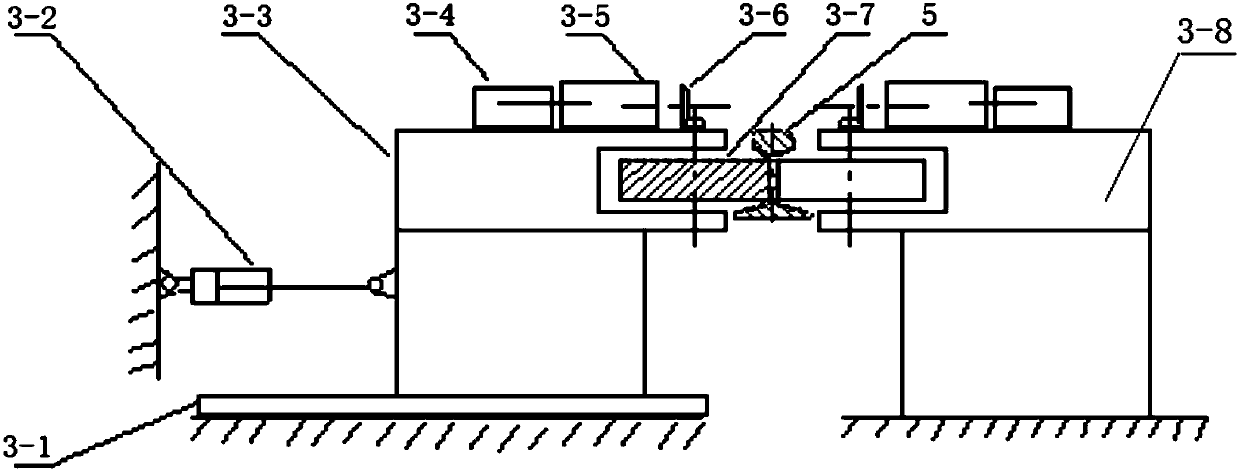

[0035] 2) Install two sets of pinch rollers 3 on both sides of the rail on the rear side of the sawing machine 4 and the front side of the laser range finder;

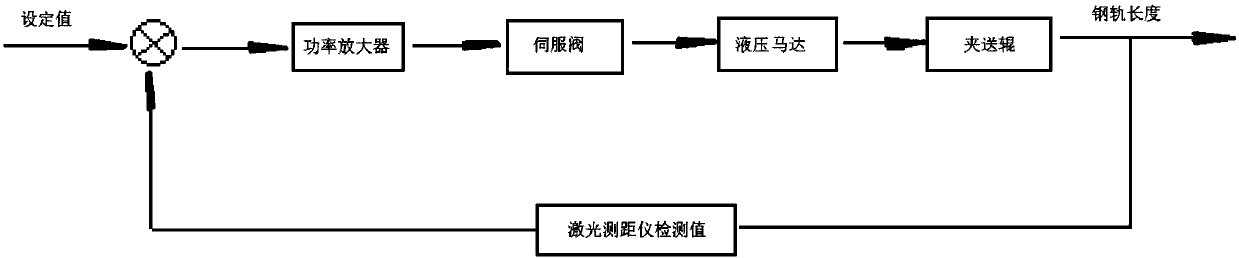

[0036] The main function of adopting two sets of pinch roller 3 devices is to facilitate the centering of the rail 5 when the two pairs of hydraulic cylinders 3-2 are clamped, and to facilitate the laser detection of the end face of the rail 5. Because the power of the hydraulic motor 3-4 of one set of pinch rollers 3 can meet the requirements o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com