A clean composite solid gas generating agent and its preparation method

A gas generating agent and technology of generating agent, which are applied to attack equipment, explosives, nitrification explosive components, etc., can solve the problems of easy hygroscopicity, high synthesis cost, non-hygroscopicity of oxidants, and achieve low cost, low gas residue content, and hygroscopicity. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

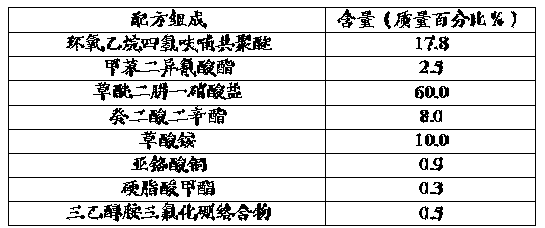

[0042] (1) Composition of gas generating agent

[0043]

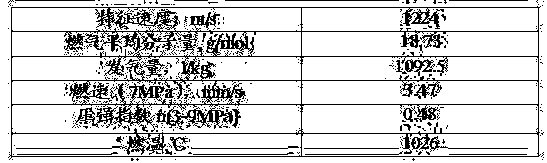

[0044] (2) Performance of gas generating agent

[0045]

[0046] The preparation process of Example 1 is as follows: weigh each component in the formula according to the proportion, and after premixing the liquid component and the small component, add the solid component and the curing agent to the vertical mixer in sequence for mixing, and the mixing temperature is 50°C ~70℃, mixing time 60min~100min. Vacuum spray pour the slurry into the mold or into the engine, and then put it in an oil bath oven at 50°C to 70°C to cure for 7 days.

Embodiment 2

[0048] (1) Composition of gas generating agent

[0049]

[0050] The preparation process of embodiment 2 is the same as embodiment 1.

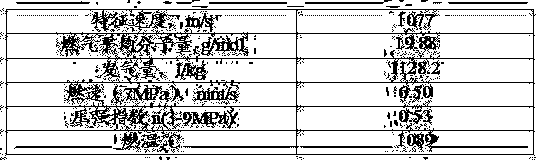

[0051] (2) Performance of gas generating agent

[0052]

Embodiment 3

[0054] (1) Composition of gas generating agent

[0055]

[0056] The preparation process of embodiment 3 is the same as embodiment 1.

[0057] (2) Performance of gas generating agent

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com