Novel automatic winding machine device

A technology of a winding device and a winding machine, which is applied in the directions of winding strips, transportation and packaging, and thin material handling, etc., can solve the problems of loose fabric, misalignment of the wound fabric, and complex structure of the winding machine, and achieves good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

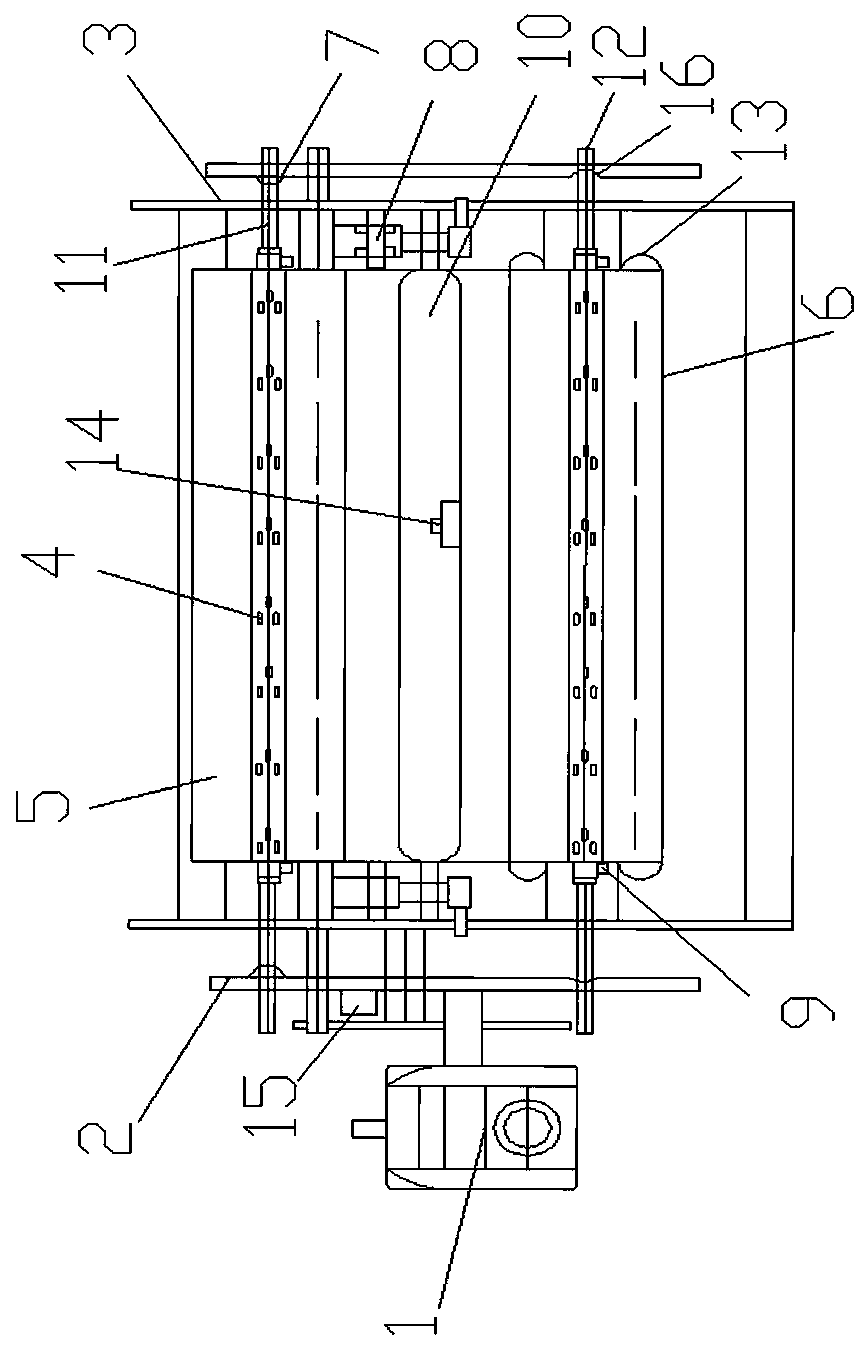

[0014] Such as figure 1 As shown, a new type of automatic winder device includes a winding device axially arranged on the winder frame 3, and also includes a side plate 2 longitudinally installed on the first bearing 11 and the second bearing 12, and also includes Including the drive gear reduction motor 1;

[0015] The winding device includes a first roller 5, a second roller 6 and a heating roller 10 arranged horizontally, the first roller 5 is fixed on the side plate 2 through the bayonet 7, and a group of symmetrical pressure sensors are arranged on the outer sides of the first roller 5 9. The second roller 6 is movably worn on the side plate 2 and a group of symmetrical pressure sensors 9 are arranged at both ends thereof; the heating roller 10 is a hollow structure, and a temperature sensor 14 for real-time temperature collection and data transmission is placed inside it ;

[0016] A displacement sensor 8 is arranged between the side plate 2 and the winding device, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com