Asynchronous motor winding with five-phase power sources

A technology for asynchronous motors and windings, applied to asynchronous induction motors, the shape/style/structure of winding conductors, electrical components, etc., can solve the problems of increasing system switching losses, etc., to reduce harmonic times, reduce noise, and improve utilization The effect of torque density with

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

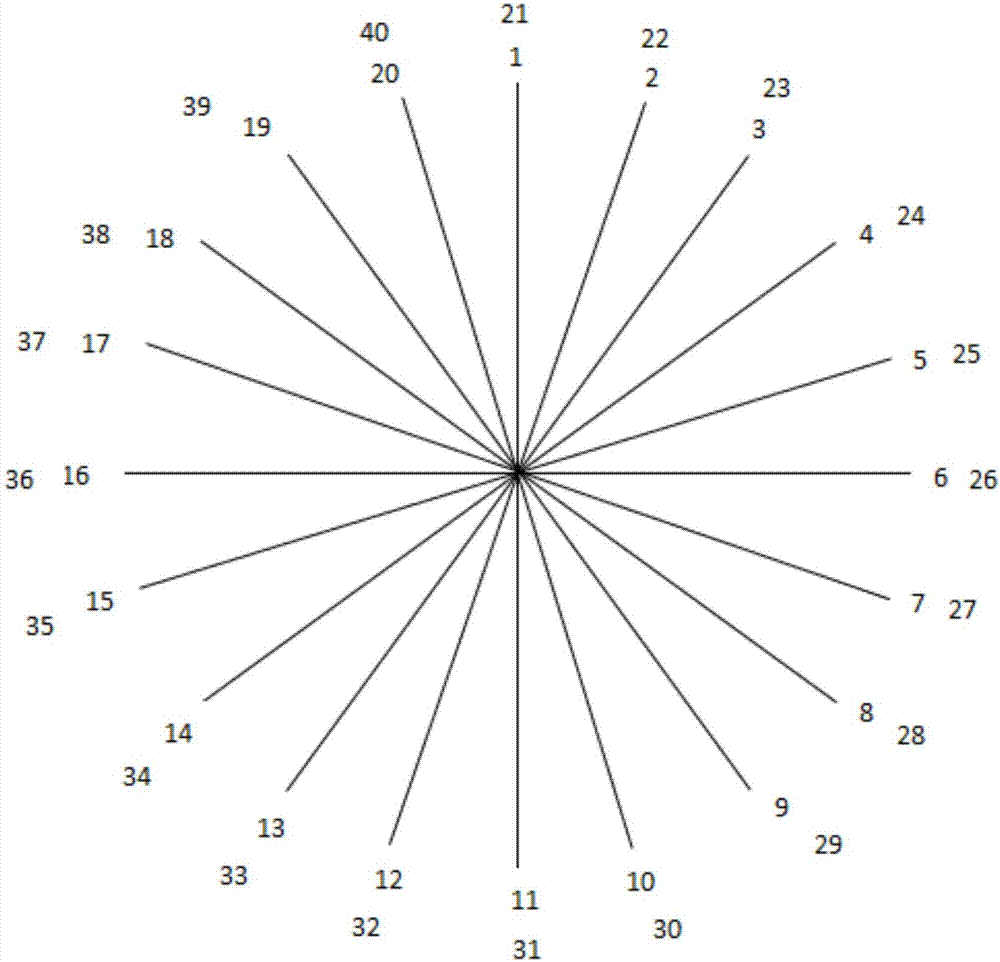

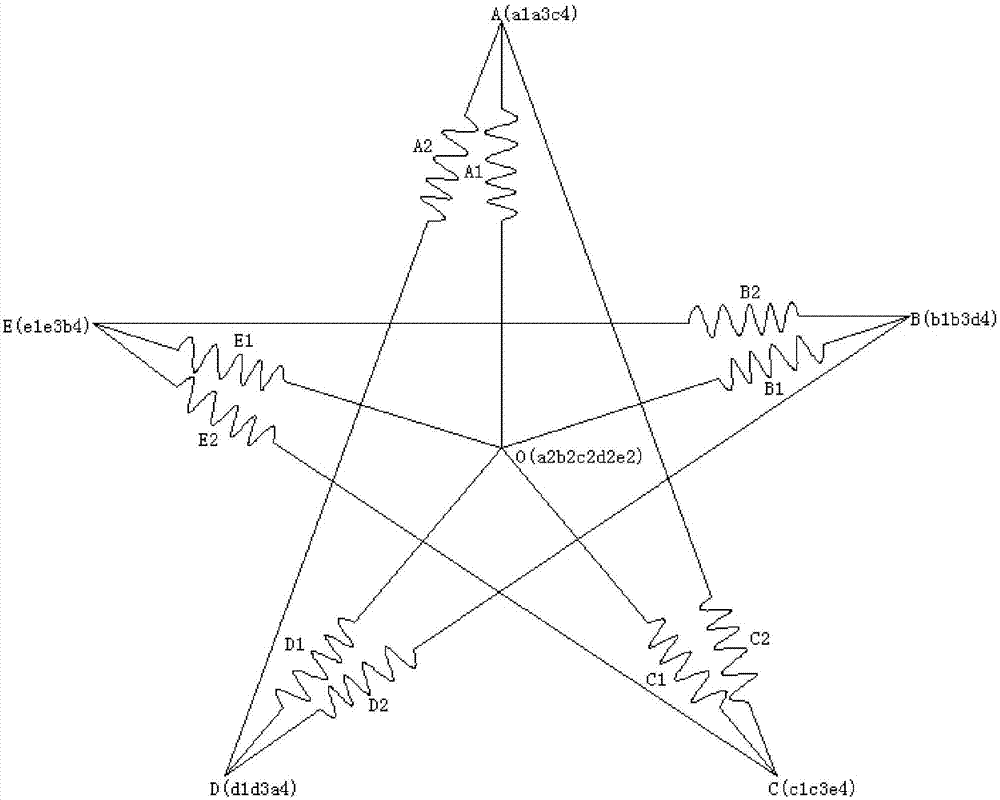

[0029] Specific implementation mode one: combine Figure 1-Figure 3 To illustrate this embodiment, a power supply of this embodiment is a five-phase asynchronous motor winding, the number of stator slots is 40, the number of poles is 4 poles, and a single-layer winding. From the inside of the motor, there are 10 branches in total, which are respectively A1, A2, B1, B2, C1, C2, D1, D2, E1, E2; each branch is composed of two coils, and the pitch of each coil is an integral pitch, and the head end of A1 branch is marked as a1, The tail end is marked as a2; the head end of the A2 branch is marked as a3 and the tail end is marked as a4; the head end of the B1 branch is marked as b1 and the tail end is marked as b2; the head end of the B2 branch is marked as b3 and the tail end It is marked as b4; the head end of C1 branch is marked as c1, and the tail end is marked as c2; the head end of C2 branch is marked as c3, and the tail end is marked as c4; the head end of D1 branch is marke...

specific Embodiment approach 2

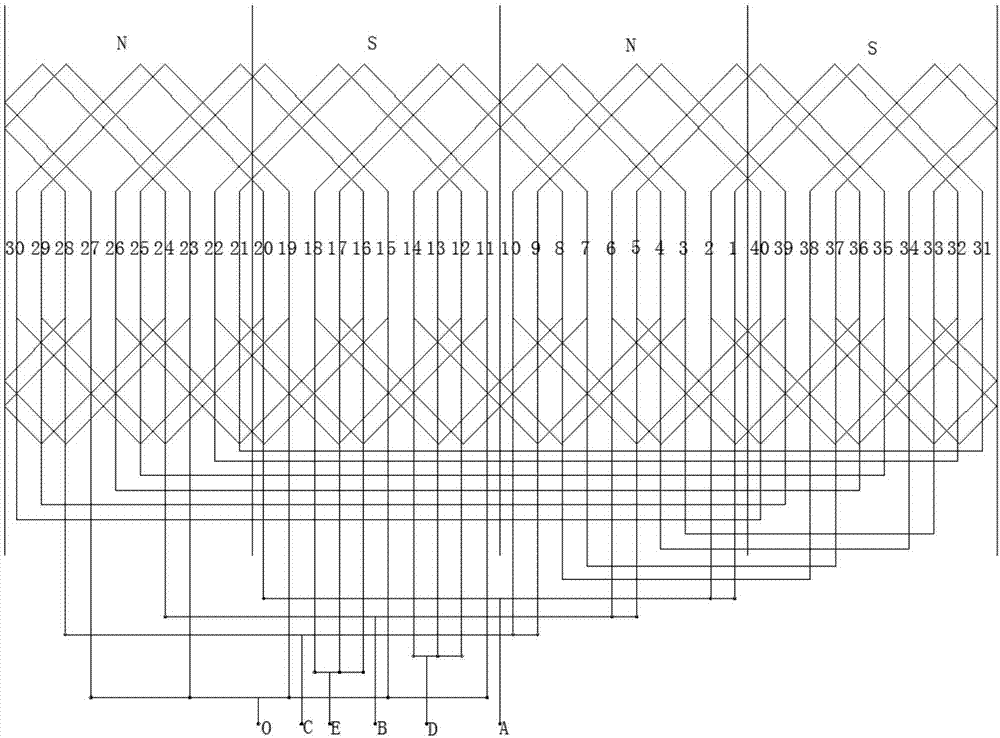

[0031] Specific implementation mode two: combination image 3 To illustrate this embodiment, a power supply of this embodiment is a five-phase asynchronous motor winding, and the A1 branch is composed of two coils, of which 1-31 are connected to form the first coil, and 21-11 are connected to form the second coil , and then connect the two coils in series, that is, connect the tail end 31 of the first coil to the head end 21 of the second coil, and lead out from the head end 1 of the first coil and the tail end 11 of the second coil. Get the head end a1 and tail end a2 of the A1 branch;

[0032] The A2 branch is composed of 2 coils, among which 2-32 are connected to form the first coil, 22-12 are connected to form the second coil, and then the two coils are connected in series, that is, the tail end 32 of the first coil is connected to the second coil. The head ends 22 of the two coils are connected, drawn from the head end 2 of the first coil and the tail end 12 of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com