Distribution box heat dissipation system

A heat dissipation system and distribution box technology, applied in substation/power distribution device casing, electrical components, substation/switch layout details, etc., can solve problems affecting the operation of electrical components in the distribution box, and achieve the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail through specific embodiments below.

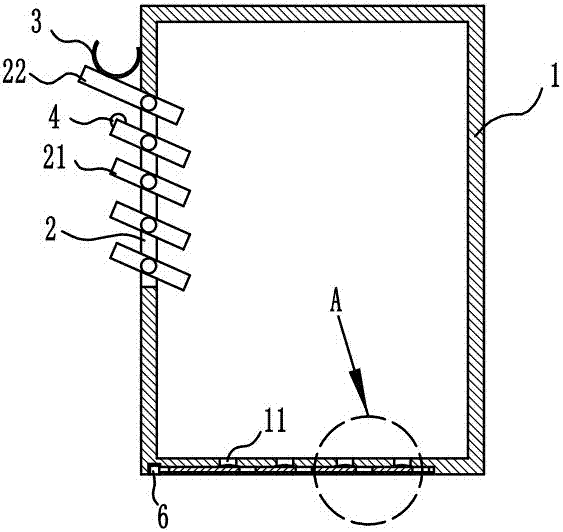

[0027] The reference signs in the accompanying drawings of the description include: box body 1, heat dissipation hole 2, water bag 3, photoresistor 4, mounting frame 5, telescopic cylinder 6, slider 7, rotating shaft 8, torsion spring 9, air vent 11, slider Groove 12, spacer 21, blocking plate 22, sealing plate 51, through hole 52.

[0028] Distribution box cooling system, such as figure 1 , figure 2 and image 3 As shown, a box body 1 is included, electrical components are installed in the box body 1, a heat dissipation hole 2 is opened on the box body 1, and a plurality of spacers 21 are arranged in the heat dissipation hole 2, and four spacers 21 are arranged in the present embodiment. Sheets 21 and spacers 21 are arranged in an inclined downward manner from the outside of the box body 1 toward the inside of the box body 1. The top of the cooling hole 2 is hinged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com