Heat conduction tube performance tester

A detection device and heat pipe technology, which is applied in the detection field, can solve the problems of troublesome addition of materials outside the heat pipe and inability to measure, and achieve the effects of fast material combination, convenient material replacement, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

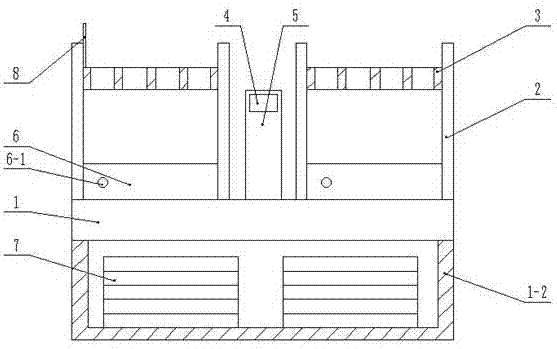

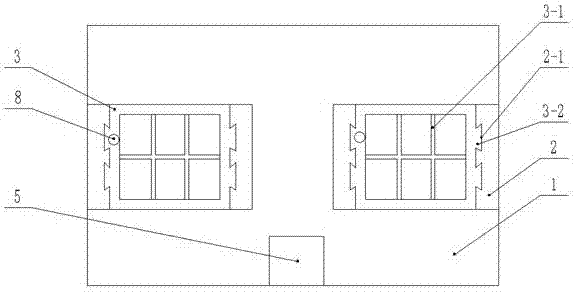

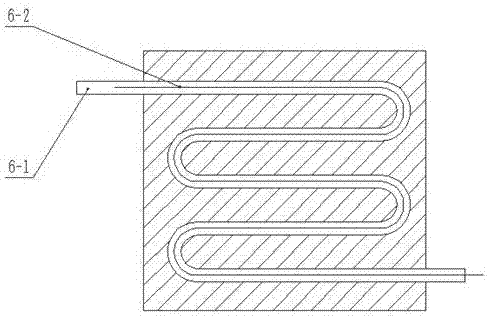

[0013] Such as figure 1 , figure 2 ,, image 3 As shown, a heat pipe performance detection device includes a device base 1, two detection devices are arranged above the device base 1, and the detection device includes two plates 2 welded on the device base 1, the plates 2 There are two vertical dovetail grooves 2-1 in the middle of the opposite surface, and a dovetail groove slider 3-2 that can slide vertically is installed in the dovetail groove 2-1, and the dovetail groove slider 3-2 is connected with the square plate 3, the middle of the square plate 3 is welded with a floor grid 3-1, a thermometer 8 is installed on the edge of the square plate 3, a cement block 6 is placed at the bottom of the detection device, and there are row cloth heat pipe 6-1, the heat pipe 6-1 is inserted with a resistance wire 6-2, the resistance wire 6-2 is conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Edge thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com