Method for performing strain field measurement on inflatable structure by utilizing photogrammetric technology

A technology of inflatable structure and photogrammetry, which is applied in the field of strain testing, can solve the problems affecting measurement accuracy, difficult to remove, irrelevant speckle, etc., to achieve the effect of solving difficult measurement and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

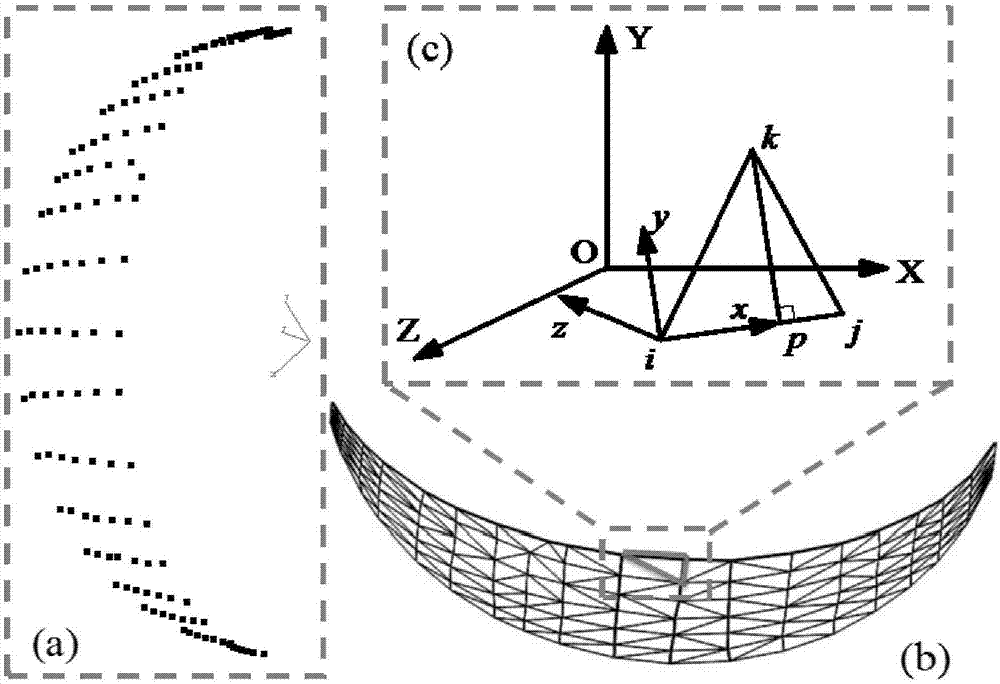

[0021] Specific implementation mode one: as figure 1 As shown, this embodiment discloses a method for measuring the strain field of an inflatable structure using photogrammetry technology, and the steps of the method are as follows:

[0022] Step 1, obtaining the surface point cloud of the inflatable structure before and after deformation by photogrammetry technology;

[0023] Step 2, matching the same points before and after deformation, so that the points before and after deformation correspond one-to-one;

[0024] Step 3, using the Delaunay (Delaunay) triangulation algorithm to discretize the point cloud into triangular sets;

[0025] Step 4, establish a unit coordinate system for each triangular unit, and convert the overall coordinates of the corner points of the triangular unit to the unit coordinate system through the coordinate transformation matrix;

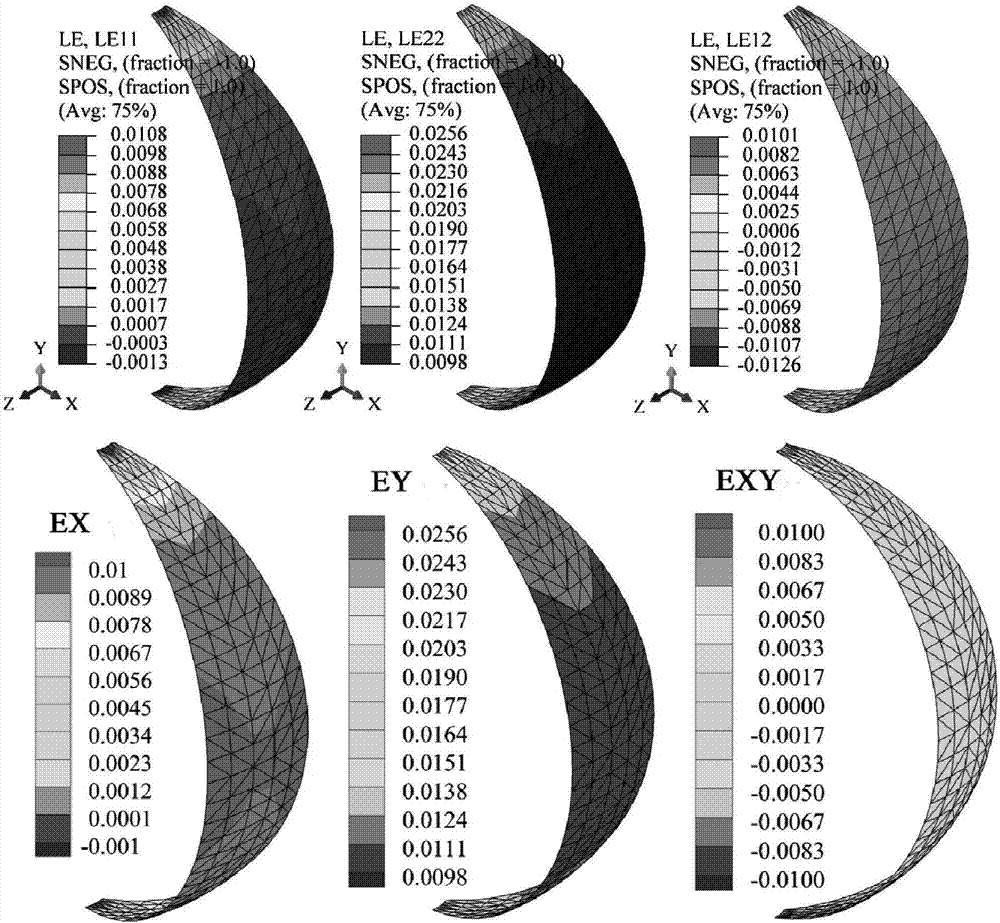

[0026] Step five, using the finite element method and the knowledge of elastic mechanics, calculate the strain of th...

specific Embodiment approach 2

[0028] Specific embodiment 2: This embodiment is a further description of specific implementation 1. The process of obtaining the surface point cloud of the inflatable structure before and after deformation through photogrammetry described in step 1 is specifically:

[0029] Paste the target points on the surface of the structure to be tested; calibrate the digital camera; take photos; import the photos into photogrammetry processing software; mark the target points in each photo; detect the coded marker points and reference rulers; identify the same points in different photos ; Calculate the three-dimensional space coordinates of the target point by beam adjustment, so as to obtain the point cloud of the target point on the surface of the structure to be measured.

specific Embodiment approach 3

[0030] Specific embodiment 3: This embodiment is a further description of specific embodiment 1. The process of matching the same points before and after deformation as described in step 2, so that the points before and after deformation correspond to each other is specifically as follows:

[0031] The coded mark points under different working conditions have the same number, and the target points are numbered by using the relative positions of the target point, the coded mark point and the reference bar, so that the same point numbers before and after deformation are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com