Paper aligning positioning bookbinding stapler base

A technology for alignment and positioning and stapler, which is applied in the direction of binding, can solve the problems of staple deviation, inconsistent binding position, uneven paper, etc., and achieve the effect of simplifying the binding process and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

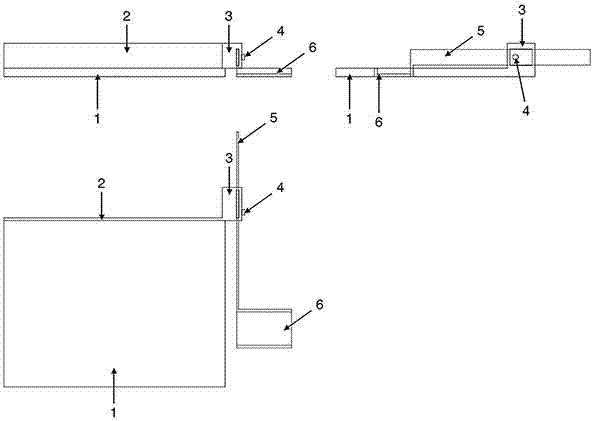

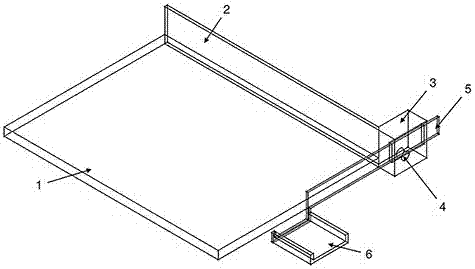

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0011] When in use, put the paper on the cardboard 1, align the adjacent two sides of the paper with the top baffle 2 and the side baffle 5, and place the stapler on the stapler base 6 to clamp it tightly. The seat 6 can be dragged up and down in parallel to change the position under the action of the guide hole 3 of the side baffle and the side baffle 5. When the stapler is dragged to the desired position, tighten the side baffle positioning screw 4. At this time, the side baffle Plate 5 is inactive, and the position of stapler base 6 cannot be changed, and just can implement appointed position binding at this moment.

[0012] An embodiment of the present invention has been described in detail above, but the content is only a preferred embodiment of the present invention, and is not intended to limit the present invention. Any minor modifications, equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com