Cage system with detachable bottom net

A bottom net and cage technology, applied in the field of cage systems, can solve the problems of poor personal safety and high labor intensity of breeding workers, and achieve the effects of facilitating breeding operations, improving work efficiency and reducing volume loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Refer to the attached drawings (the anchoring foundation and the cage system are connected by anchor chains as the prior art, not marked in the attached drawing):

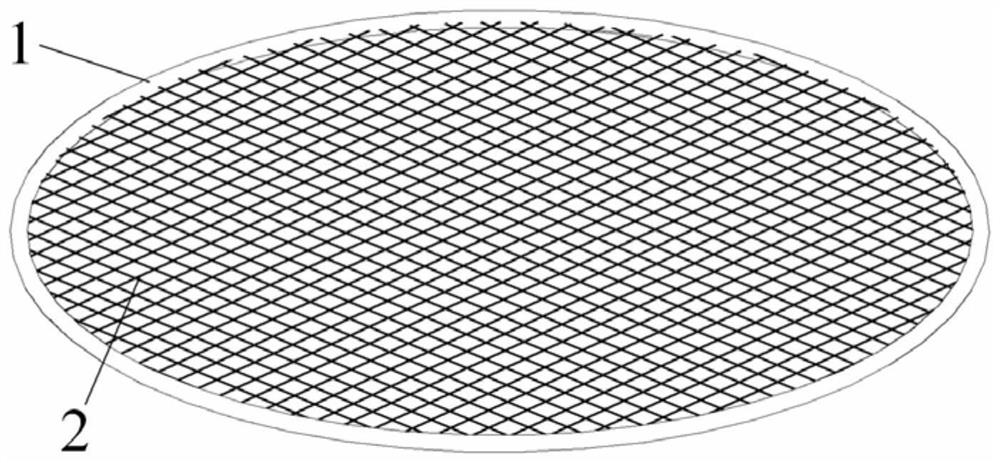

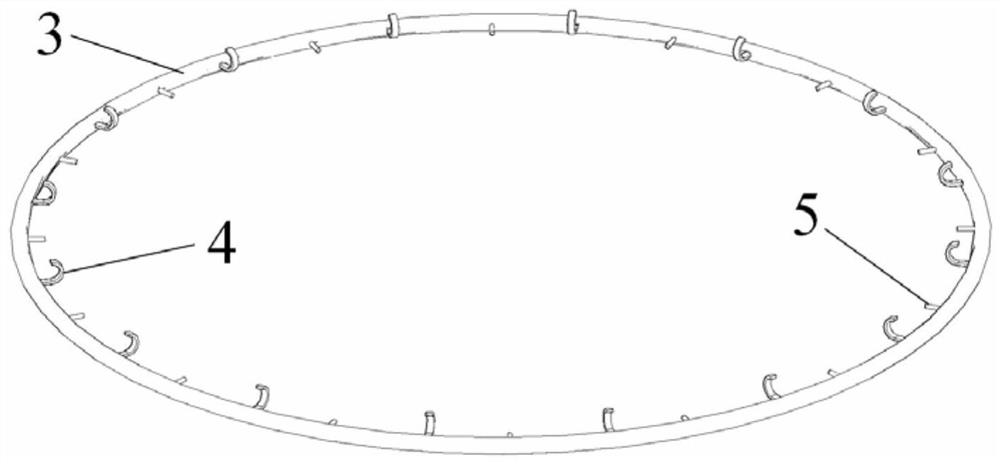

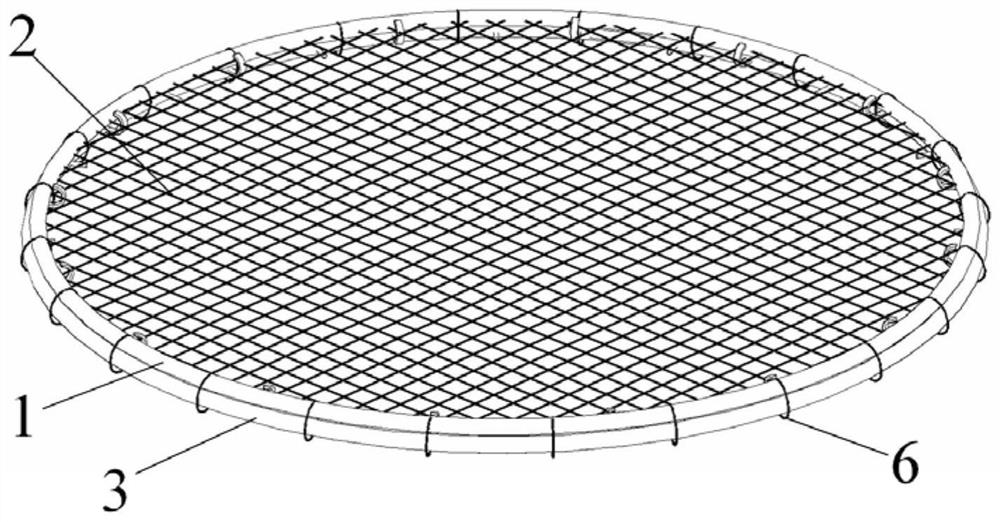

[0040] A cage system with a detachable bottom net, including an anchoring foundation, a cage frame 7, and a side net of the net. The sinker 11 is suspended at the lower end of the side net. The bottom net is composed of the inner bound net of the bottom net frame 1. A bottom net fixing frame 3 is bound to the vertical force line at the bottom of the side net, and the bottom net frame 1 of the bottom net is evenly bound to the bottom net fixing frame 3 based on the rope 6, thereby realizing the bottom net and the side net Assemble; the side nets are evenly spaced to bind a plurality of floating bags 9 with charging and exhausting pipes 10. When the net is replaced, each floating bag 9 is inflated based on the charging and exhausting pipe 10, so that the net will float up under the buoyancy of the floating bag , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com