Finite element modelling method and strength assessment method of high-strength bolt connecting structure

A high-strength bolt and connection structure technology, applied in special data processing applications, instruments, electrical and digital data processing, etc. Research and development progress, ensure the effect of design optimization and iteration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

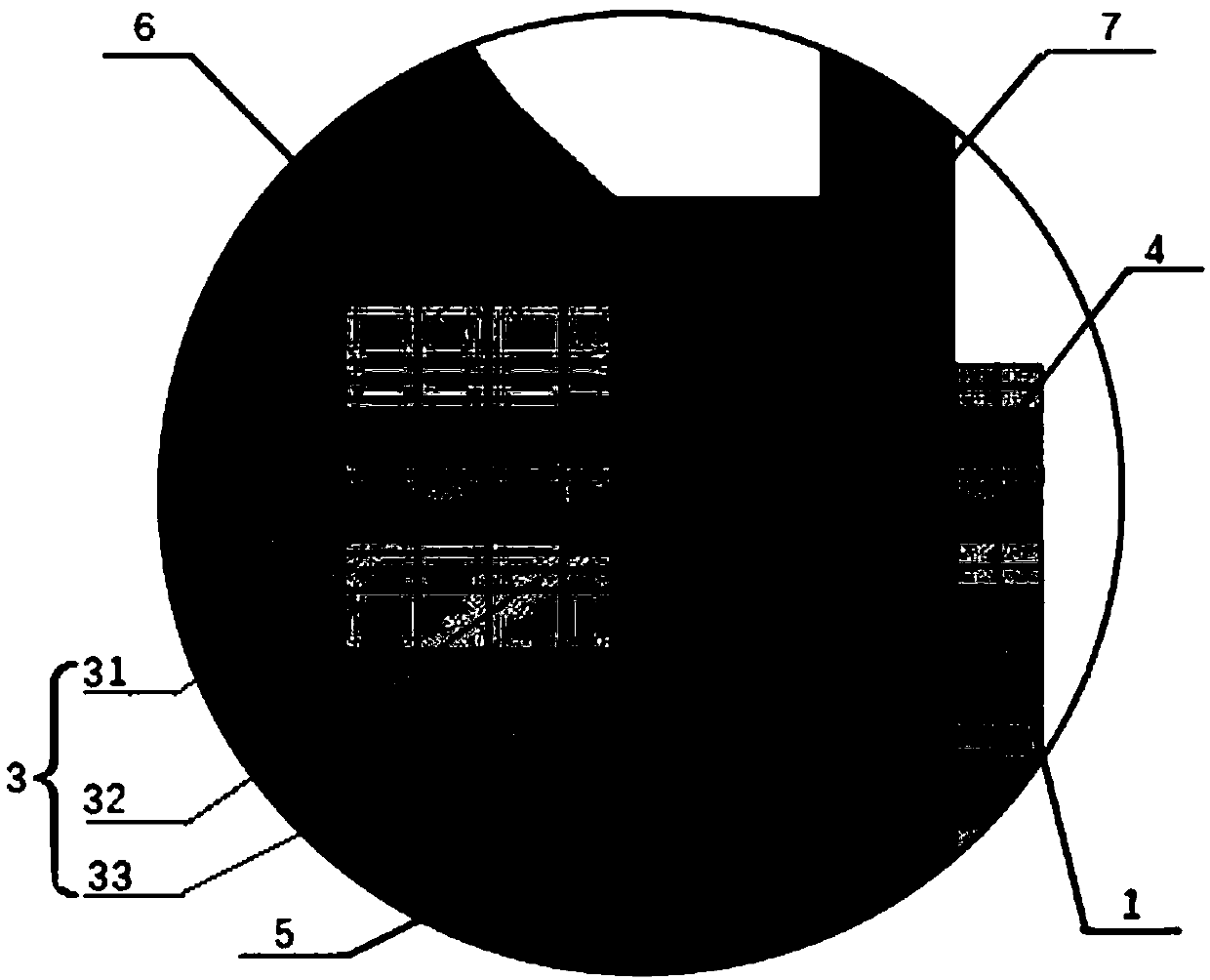

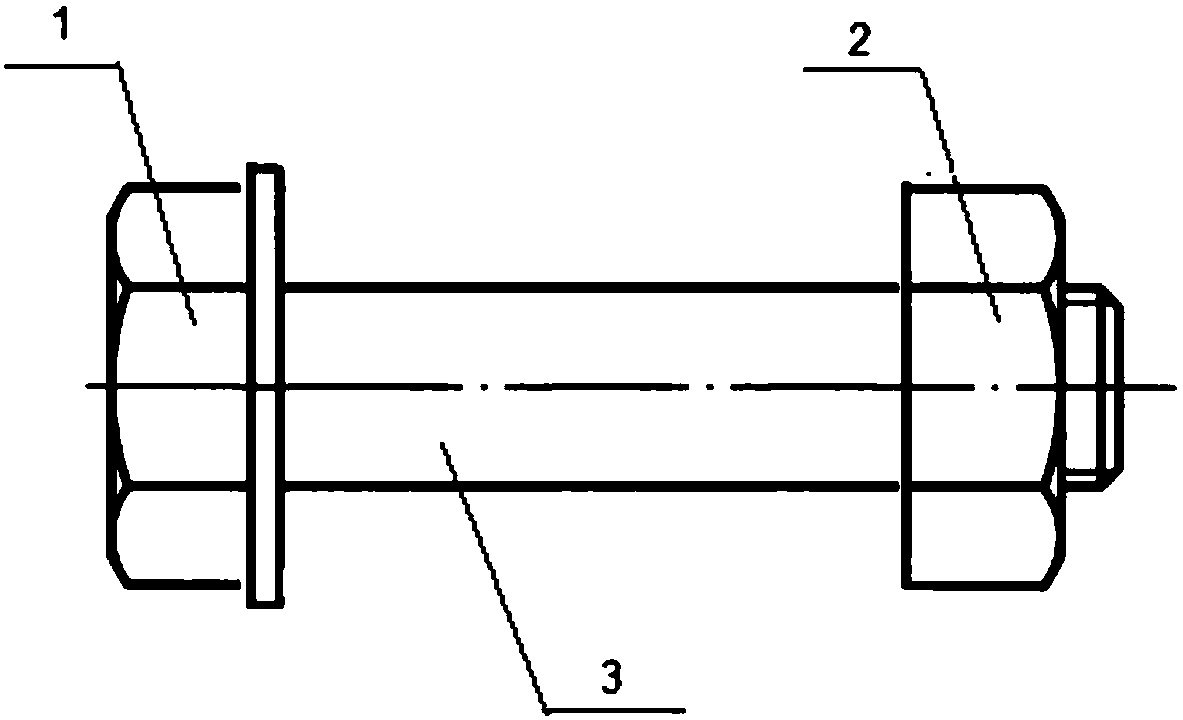

[0036] Such as Figure 1 to Figure 3 As shown, the high-strength bolt 4 connection structure includes a screw rod 3 with the same length as the high-strength bolt and a bolt head 1 located at one end of the screw rod 3, and the other end of the screw rod 3 is threaded to the clamping body. Including the following steps:

[0037] 1) Carry out three-dimensional solid modeling for the position of the threaded hole of the bolt head 1 and the clamping body: the bolt head 1 and the position of the threaded hole of the clamping body are segmented and geometrically processed to obtain several 3D geometric bodies, so that they can be scanned and generated evenly Grid conditions; sweep the 3D geometry to generate a uniform hexahedral grid;

[0038] 2) if image 3 As shown, the three-dimensional beam unit is used to simplify the simulated screw part: the screw part 3 is simplified into a straight line segment located at the axis position and equal in length to the high-strength bolt. T...

Embodiment 2

[0053] On the basis of Embodiment 1, the threaded rod 31 at the other end of the screw rod 3 adopts the nut 2 connection method to replace the threaded connection with the clamping body; correspondingly, the threaded hole position of the clamping body is replaced by the nut 2, and other suggestions Modeling method, evaluation method are identical with embodiment one step, as Figure 1 to Figure 3 shown.

Embodiment 3

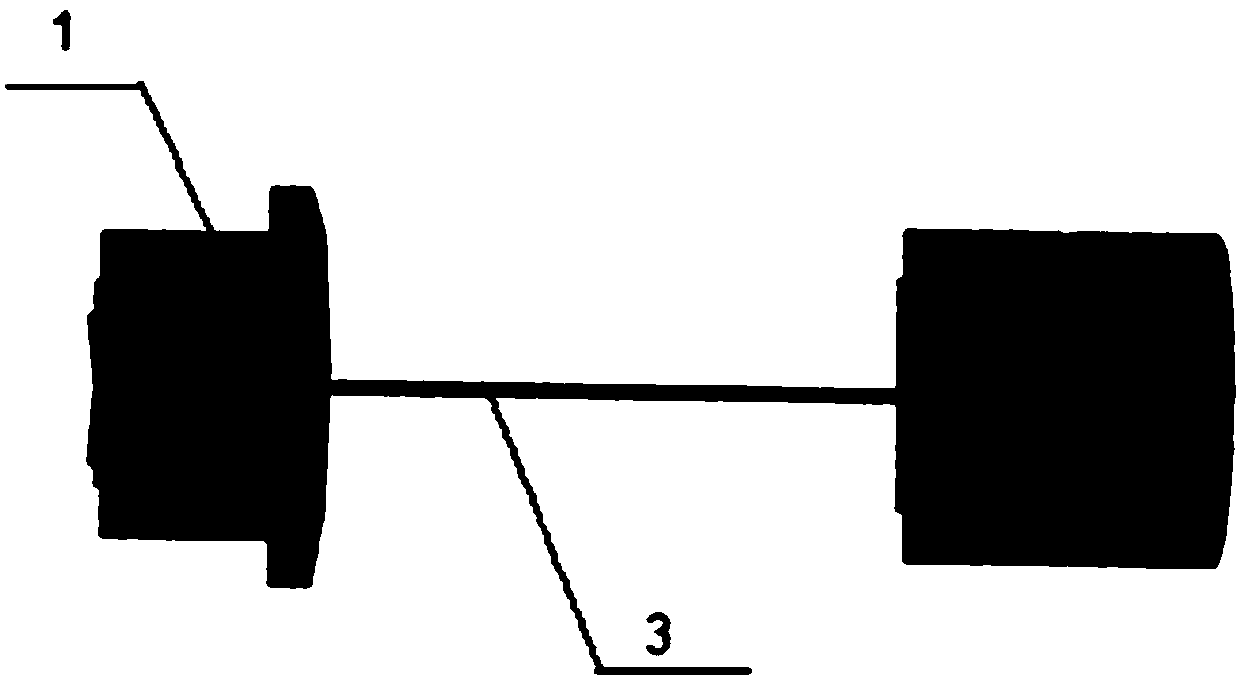

[0055] On the basis of Example 1, as Figure 4 As shown, the screw rod 3 having the same length as the high-strength bolt is replaced with a stud 4' having the same length as the high-strength bolt 4, and the bolt head 1 at one end of the screw rod 3 is replaced with the first nut 1 at one end of the stud 4' ', screw 3' is divided into threaded rod 31' and polished rod 32', the finite element modeling method of double-ended stud connection structure includes the following steps:

[0056] 1) Carry out three-dimensional solid modeling of the first nut 1' and the threaded hole position of the clamping body: segment and geometrically process the first nut 1' and the threaded hole position of the clamping body to obtain a number of three-dimensional geometry, so that it has Conditions for sweeping to generate a uniform mesh; sweeping a 3D geometry to generate a uniform hexahedral mesh;

[0057] 2) Simplify the simulated screw part with a three-dimensional beam element: Simplify th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com