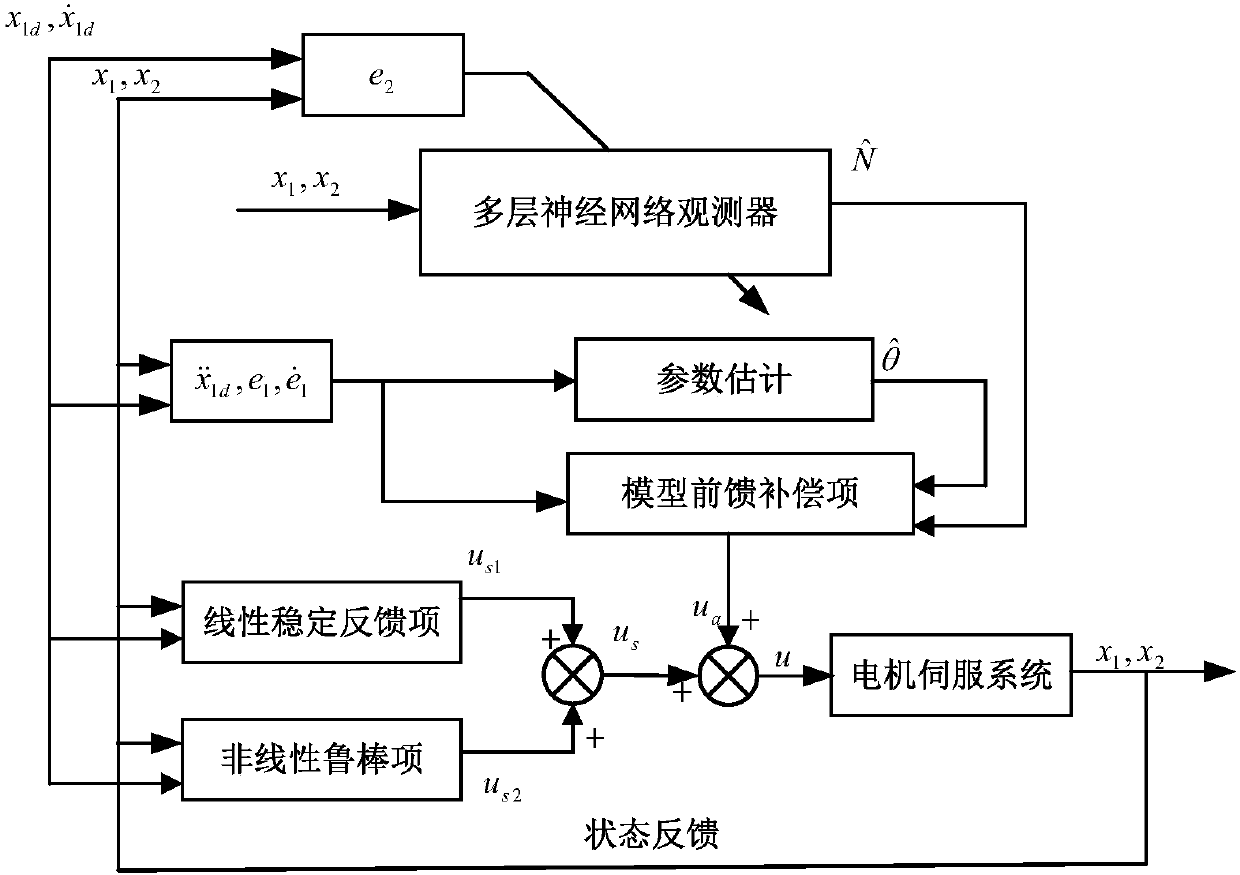

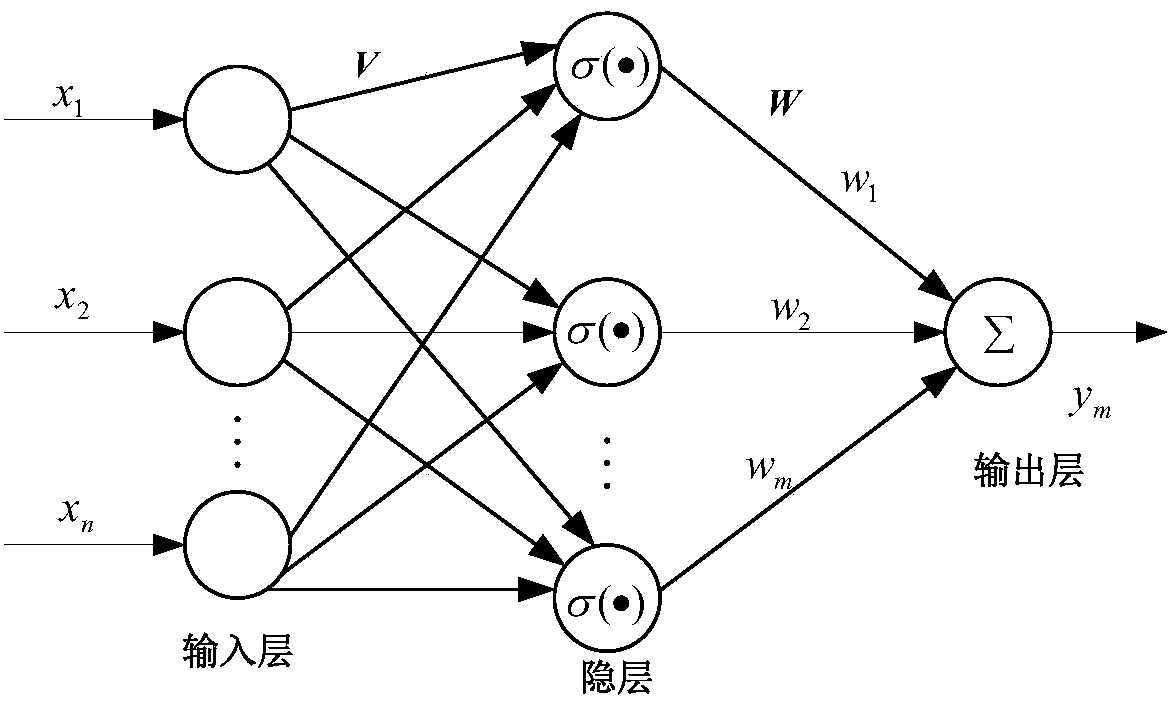

Multilayer neural network-based motor position servo system friction compensation control method

A multi-layer neural network and servo system technology, applied in the field of friction compensation control of motor position servo system based on multi-layer neural network, can solve the problems of self-excited limit cycle oscillation, inaccurate compensation, and many friction model parameters, and achieve smooth Effects of motion, high tracking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

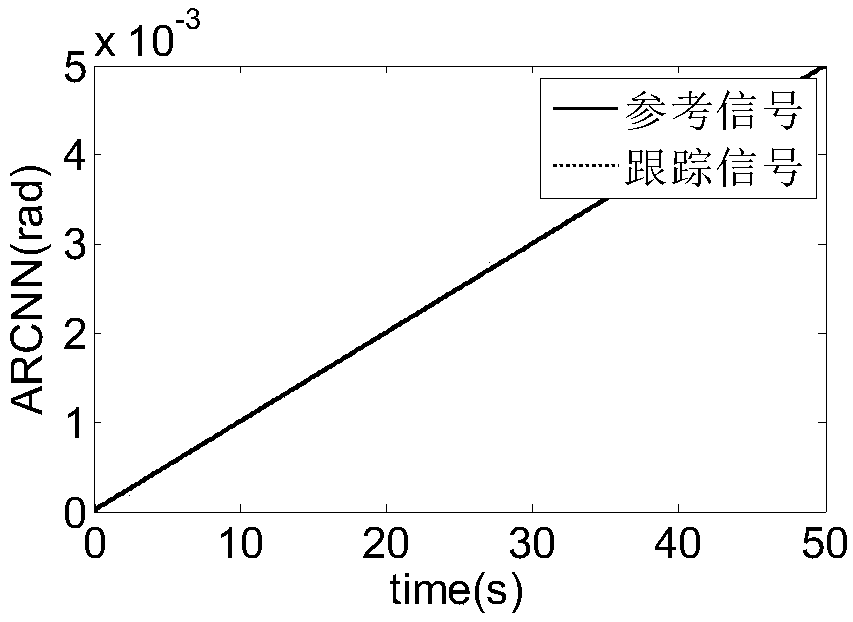

[0100] The simulation parameters are: J=0.9kgm 2 , T L =2Nm, f=0.002x 1 x 2 ,σ 0 =12Nm / rad,σ 1 =2.5Nms / rad,σ 2 =0.2Nms / rad,F s =0.34Nm,F c =0.28Nm,

[0101] The value of the motor position servo system friction compensation control method (ARCNN) based on the multilayer neural network proposed by the present embodiment is as follows: k 1 =150,k 2 =50,k=10,ε s =0.05,Γ 1 =diag{120,120,120,120,120},Γ 2 =diag{80,80},Γ 3 =diag{0.0005,0.003,0.005}

[0102] When the position reference tracking signal is a ramp signal x 1d =0.0001t, as shown in Figure 3(a), Figure 3(b), Figure 4(a), and Figure 4(b). Figure 3(a) , 3(b) It is the curve diagram of reference command signal and tracking signal under two kinds of controllers. Figure 4(a) and Figure 4(b) are the position tracking errors of the two controllers under the slope reference signal. It can be seen from the figure that a slight crawling phenomenon and a relatively large tracking error will appear at the beginnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com