Measurement device integrating self-regeneration hydrogen conductivity, anionic conductivity and total conductivity

A hydrogen conductivity and measurement device technology, applied in the direction of material resistance, etc., can solve the problems of ion exchange resins affecting measurement accuracy, etc., and achieve the effects of improving detection sensitivity, free of chemical reagent consumption, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

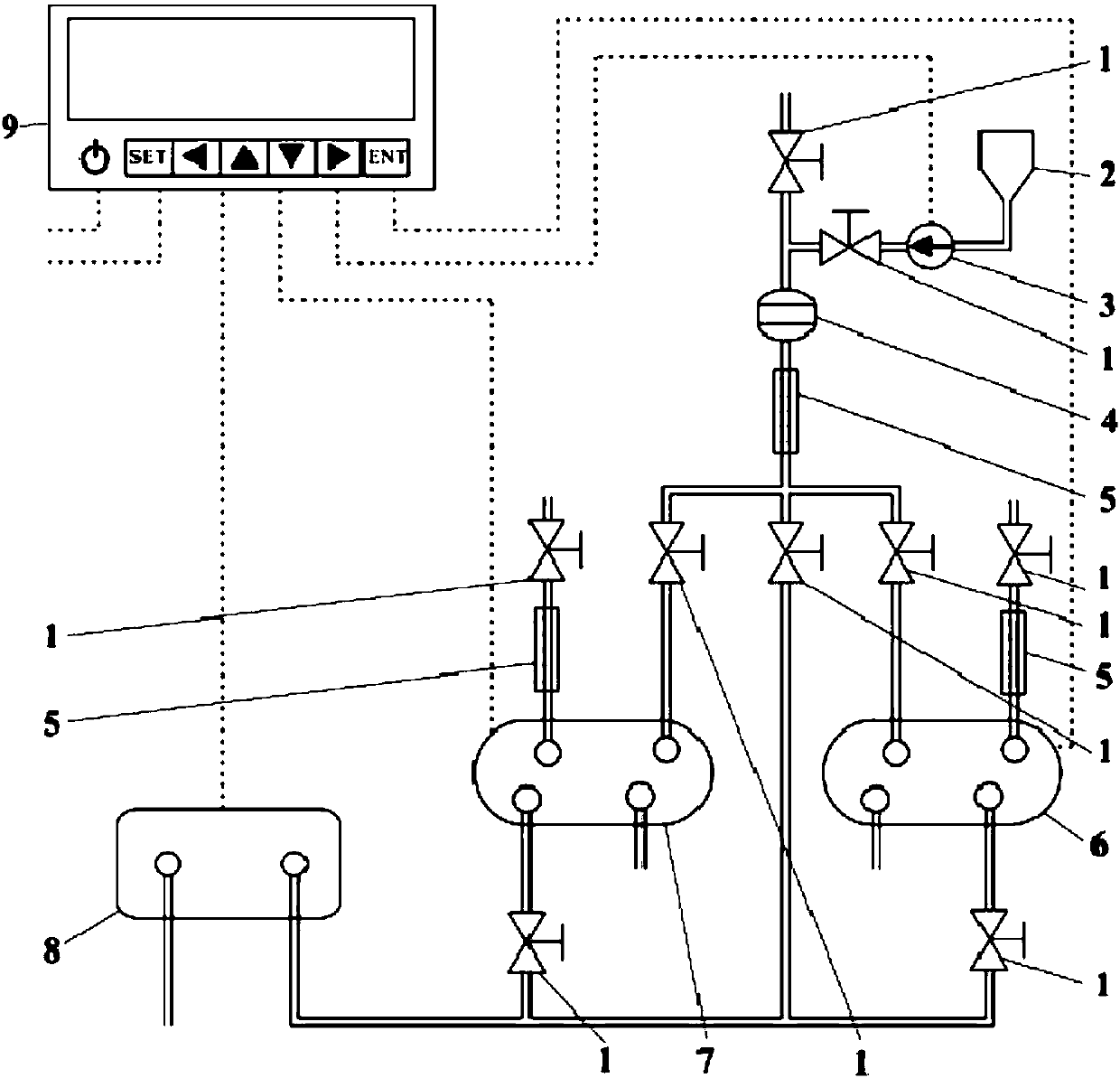

[0026] The technical scheme of the integrated self-regenerating hydrogen electrical conductivity and total electrical conductivity measuring device of the present invention will be described in detail below with reference to the drawings and specific embodiments.

[0027] Such as figure 1 As shown, the present invention is an integrated self-regenerating hydrogen electrical conductivity and total electrical conductivity measuring device, including a regulating valve 1, a calibration cup 2, a peristaltic pump 3, a filter 4, a flow meter 5, and a cationic suppressor 6 , Anion suppressor 7, conductivity detector 8, meter 9; Among them, the regulating valve 1 is made of stainless steel, and the calibration cup 2 is made of plastic.

[0028] The measuring device is connected to the system to be measured through the regulating valve 1. The regulating valve 1 is threaded to the filter 3 through a plastic pipeline, which is used to control and regulate the flow direction and flow rate of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com