Device and method for loading and measuring of large load testing machine

A loading device and large load technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the characteristics of the sensor material are not fully effective, the accuracy of the test cannot meet the requirements, and the test does not have benefits, etc., to achieve full The effect of process control, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

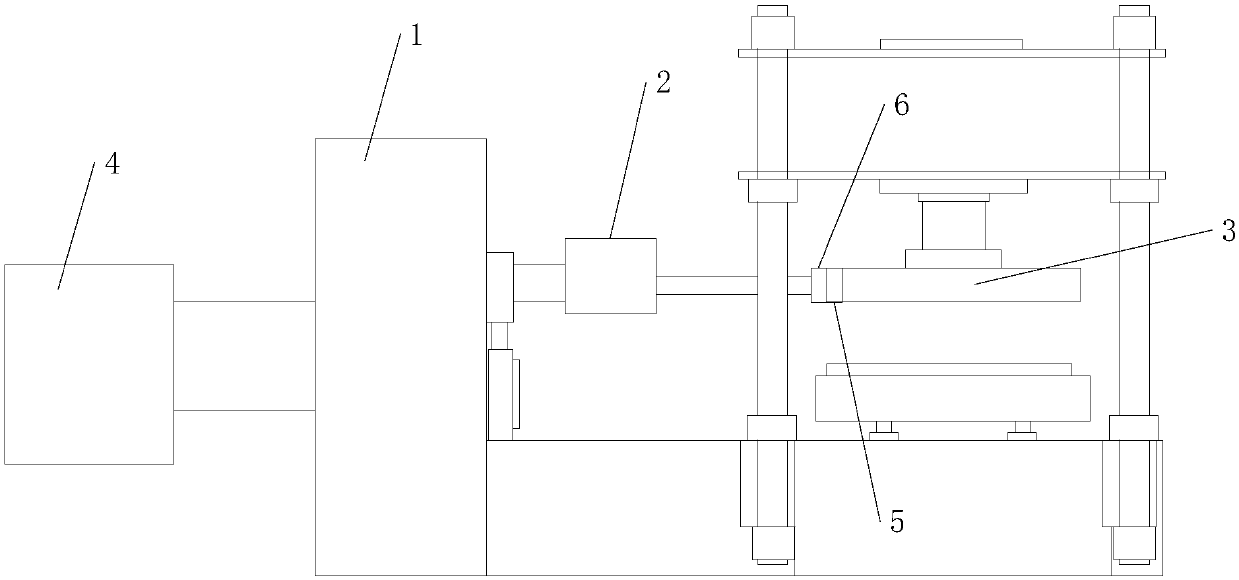

[0048] The specific operation process of the loading and measuring device of the large load testing machine is as follows:

[0049] Assemble the servo oil source 1 of the large-load loading device, the actuator 2 of the testing machine, and the test fixture 3 in sequence, and connect the servo control system 4 to the large-load testing machine. The large load sensor of the large load testing machine is connected to the test fixture 3, the displacement sensor 5 and the small load sensor 6 are connected to the actuator of the testing machine, and the servo control software is installed in the host computer connected to the controller. The loading tonnage level of the large-load testing machine is 100 tons, the maximum test load of the specimen is 10 tons, the maximum range of the selected load sensor is 20 tons, and the test tooling matches the 100-ton load sensor.

[0050] The measurement range of the displacement sensor is 4500mm, and the working speed is controlled at 3000 time...

Embodiment 2

[0053] The specific operation process of the loading and measuring device of the large load testing machine is as follows:

[0054] Assemble the servo oil source of the large load loading device, the actuator of the testing machine and the test tooling in sequence, and connect the servo control system with the large load testing machine. The load sensor of the large load testing machine is connected with the test tool, the displacement sensor and the small load sensor are connected with the actuator of the testing machine, and the servo control software is installed in the host computer connected with the controller. The loading tonnage level of the large-load testing machine is 50 tons, the maximum test load of the specimen is 5 tons, the maximum range of the selected load sensor is 8 tons, and the test tooling matches the 50-ton load sensor.

[0055] The measurement range of the displacement sensor is 4200mm, and the working speed is controlled at 2800 times / s; the displacem...

Embodiment 3

[0058] The specific operation process of the loading and measuring device of the large load testing machine is as follows:

[0059] Assemble the servo oil source of the large load loading device, the actuator of the testing machine and the test tooling in sequence, and connect the servo control system with the large load testing machine. The load sensor of the large load testing machine is connected with the test tool, the displacement sensor and the small load sensor are connected with the actuator of the testing machine, and the servo control software is installed in the host computer connected with the controller. The loading tonnage level of the large-load testing machine is 150 tons, the maximum test load of the specimen is 15 tons, the maximum range of the selected load sensor is 30 tons, and the test tooling matches the 150-ton load sensor.

[0060] The measurement range of the displacement sensor is 4800mm, and the working speed is controlled at 3500 times / s; the displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com