Shafting Fault Identification Method Based on Wavelet Threshold Noise Reduction and Adaboost

A fault identification, wavelet threshold technology, applied in the field of fault identification, can solve problems such as different effects, rough settings, excessive drying and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions adopted by the present invention will be further described below in conjunction with the accompanying drawings.

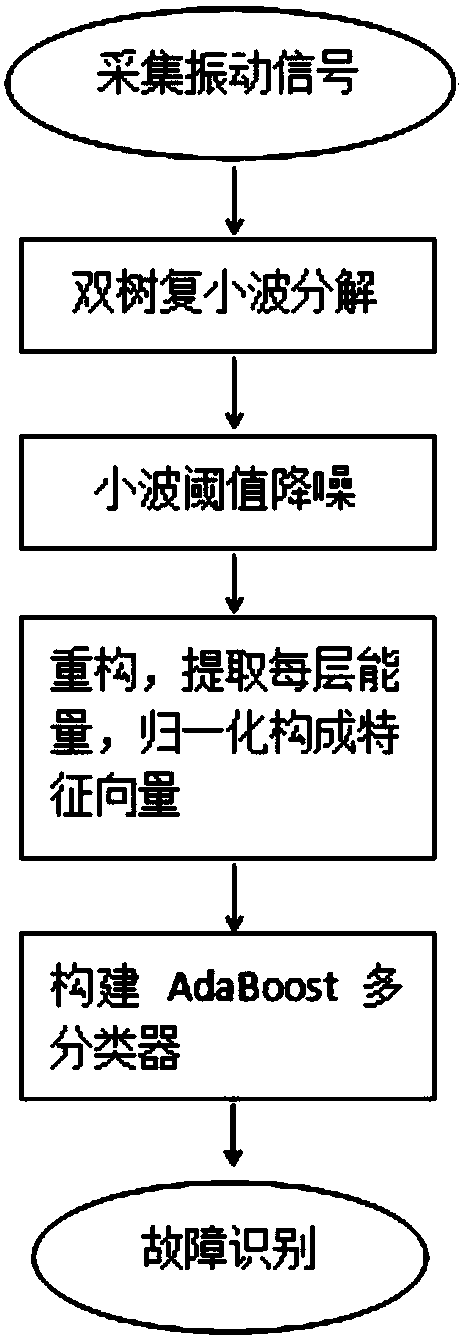

[0024] Such as figure 1 As shown in the flow chart of shafting fault identification, the shafting fault identification method based on wavelet threshold noise reduction and AdaBoost includes five steps from S1 to S5.

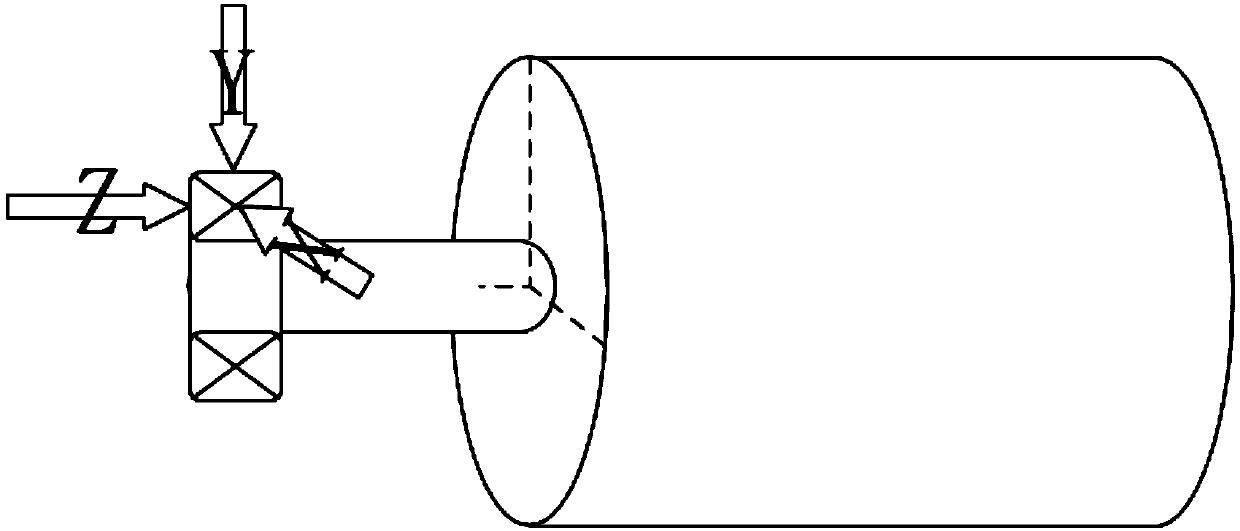

[0025] S1: Use the acceleration sensor installed on the motor bearing support frame at the industrial site, such as figure 2 Schematic diagram, obtain horizontal, vertical and axial vibration acceleration data respectively, integrate the vibration acceleration data once to obtain vibration velocity data, and take the vibration velocity data in three directions as the shafting vibration representation.

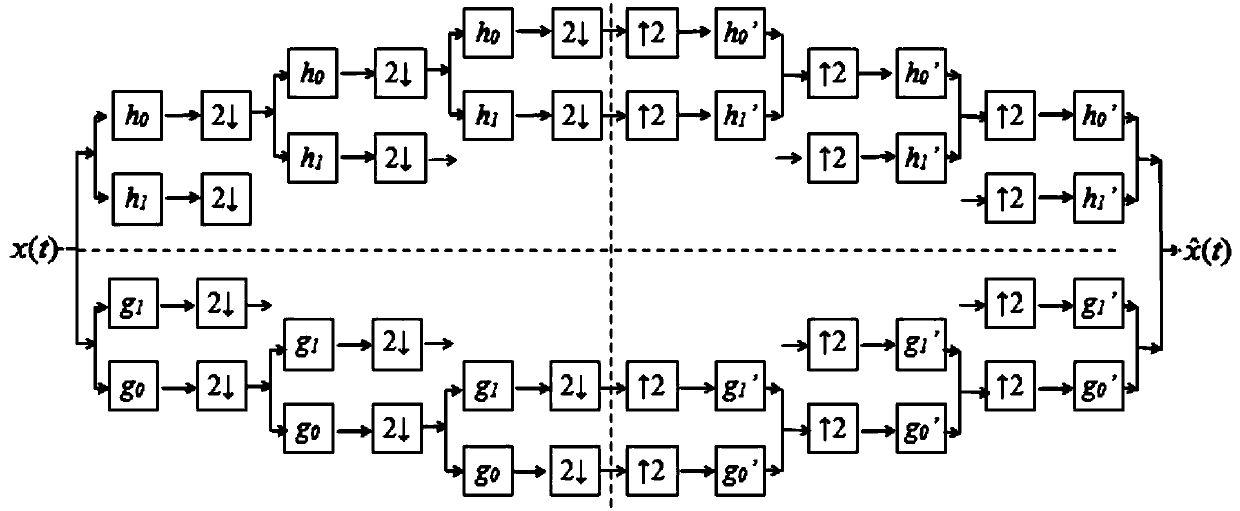

[0026] S2: Use dual-tree complex wavelet 4-layer decomposition for vibration signals in three directions respectively, and the reconstruction of dual-tree complex wavelet decomposition is as follows image 3 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com