Mounting method for bearing seat and storage method for shaft

An installation method and bearing seat technology, which are applied to the rigid brackets of bearing components, bearing components, shafts and bearings, etc., can solve problems such as cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

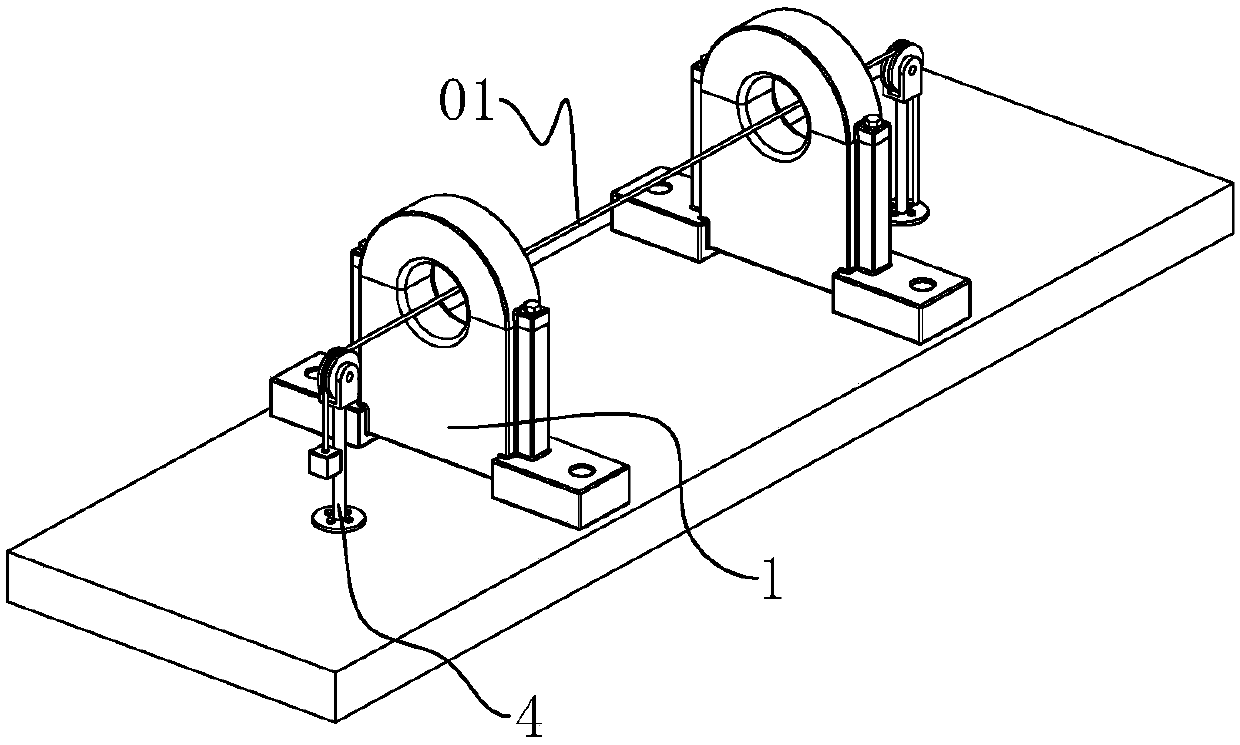

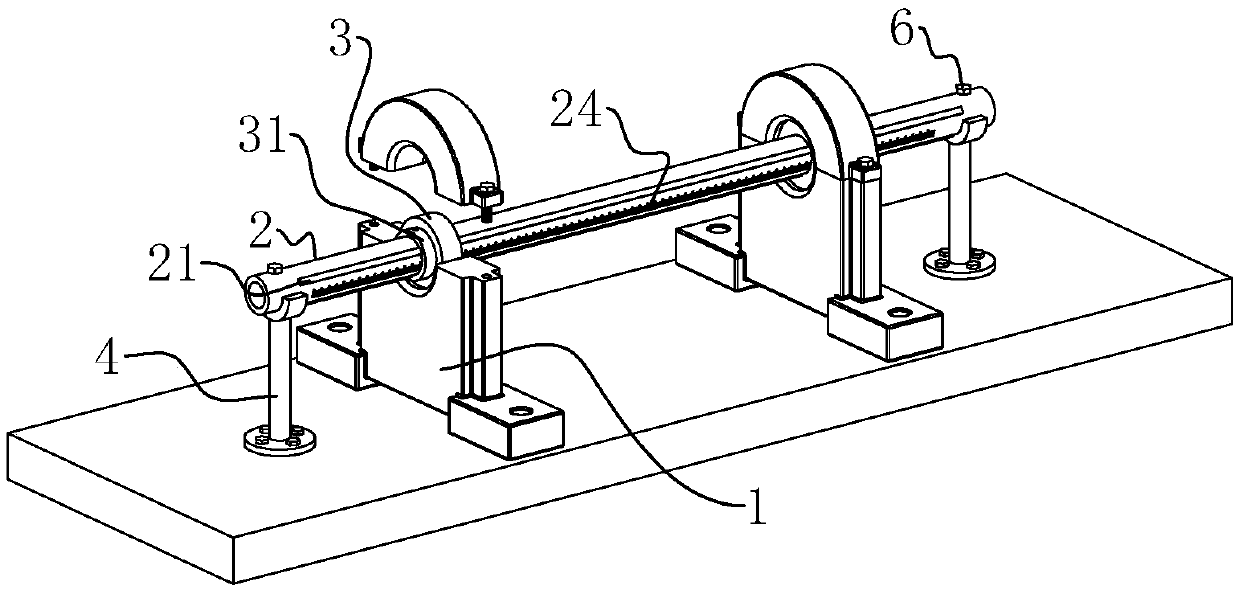

[0037] Embodiment 1: A bearing seat installation method, refer to Figure 2a and Figure 3a , and combined with the following steps,

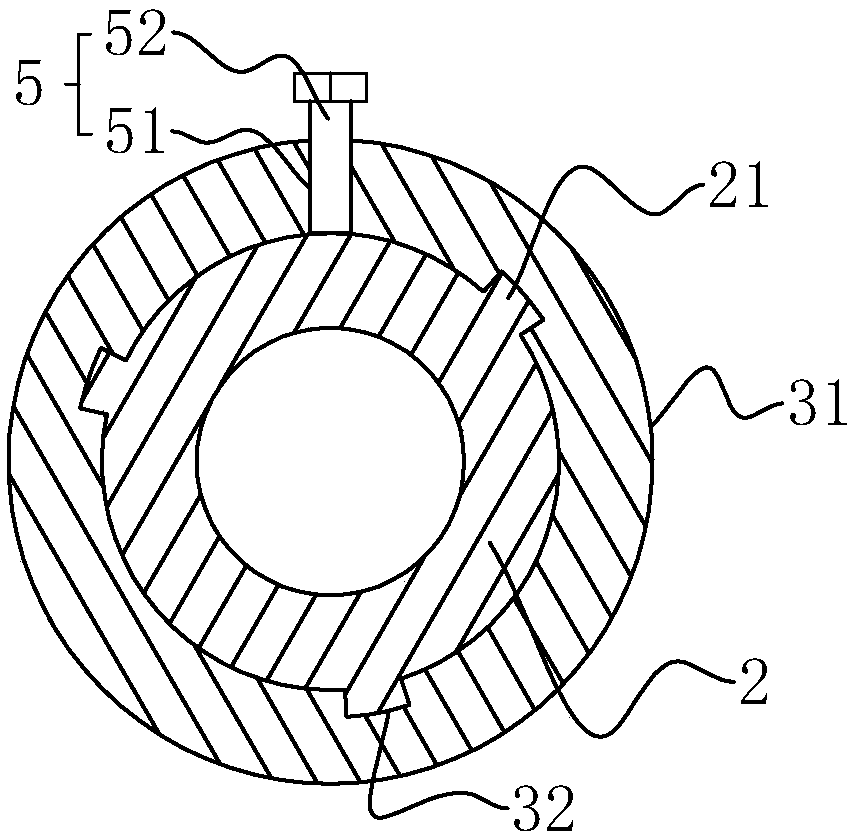

[0038] S1. Making the dummy shaft 2: Calculate the diameter of the bearing seat 1 and the tolerance of the bearing installation, and make the dummy shaft 2, and there is a disc 3 on the dummy shaft 2, and the disc 3 is used as a prosthesis to replace the bearing. When making the dummy shaft 2, generally in order to make it more accurate, the central axis of the dummy shaft 2 is used as the reference axis, and the circular jump of the disc 3 is 0.01-0.05, generally 0.01 or 0.02, which can make the installed bearing seat A precision of 1 is more accurate. In addition, the distance between the discs 3 is equal to the distance between the bearing seats 1;

[0039] S2. Measure the installation height, and fix both ends of the dummy shaft 2: calculate the height of both ends of the dummy shaft 2 according to the height of the installed bearing sea...

Embodiment 2

[0047] Embodiment 2, a storage method of shaft, such as Figure 5 As shown, one end of the false shaft 2 in Example 1 is fixed, and then it is fixed by the rope 7 and the false shaft 2 is hoisted in the air for storage. This storage method can prevent the false shaft 2 from bending due to its own weight. . During the hoisting process, the rod 8 can be passed through the through hole 23 and then the rope 7 and the rod 8 are fixed to complete the hoisting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com