Vibration flattening mechanism

A leveling machine and platen technology, applied in external support, transportation packaging, packaging, etc., can solve the problem of long investment in automatic vacuuming conveyor lines, etc., to meet the needs of production and processing, reasonable structural design, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

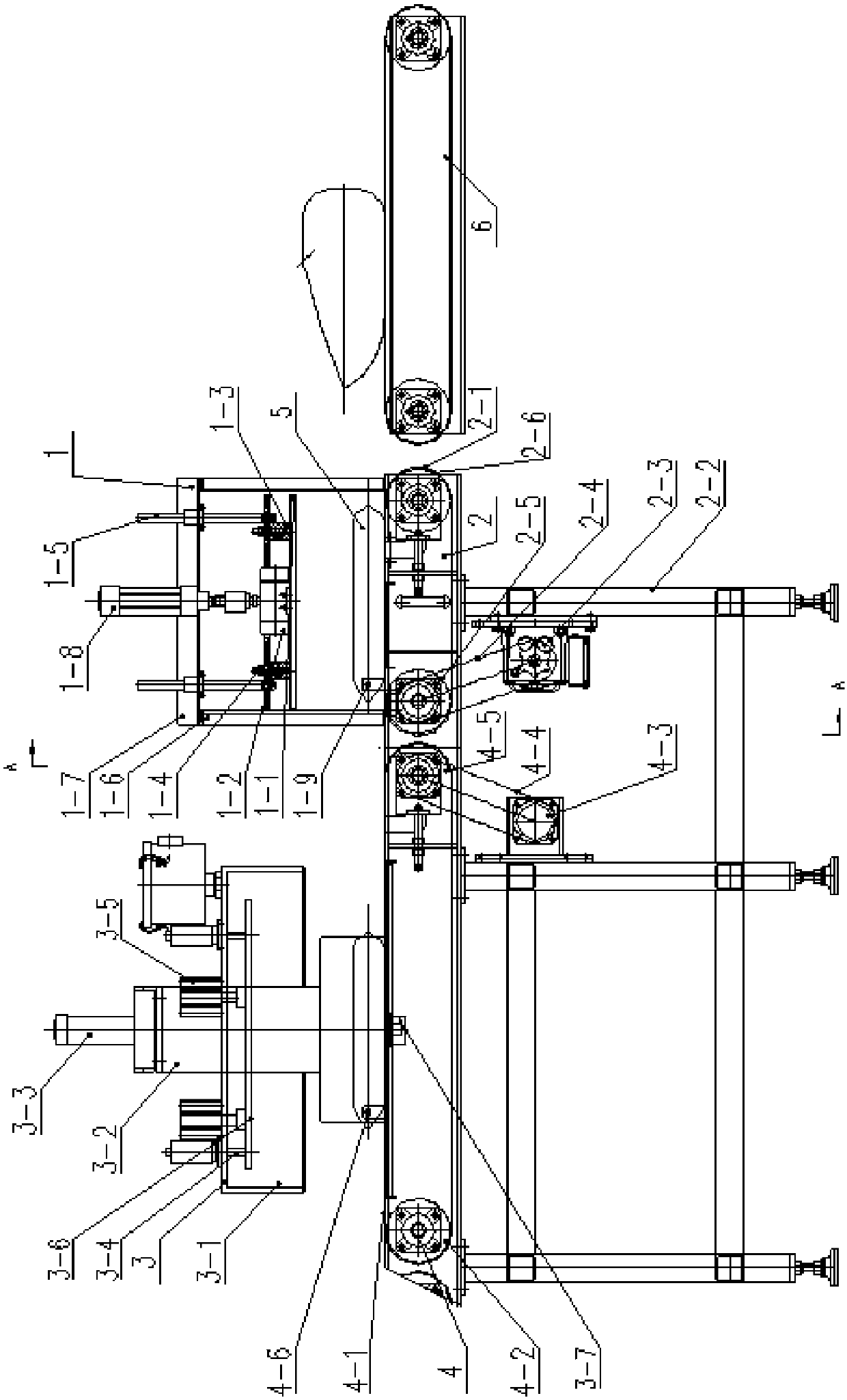

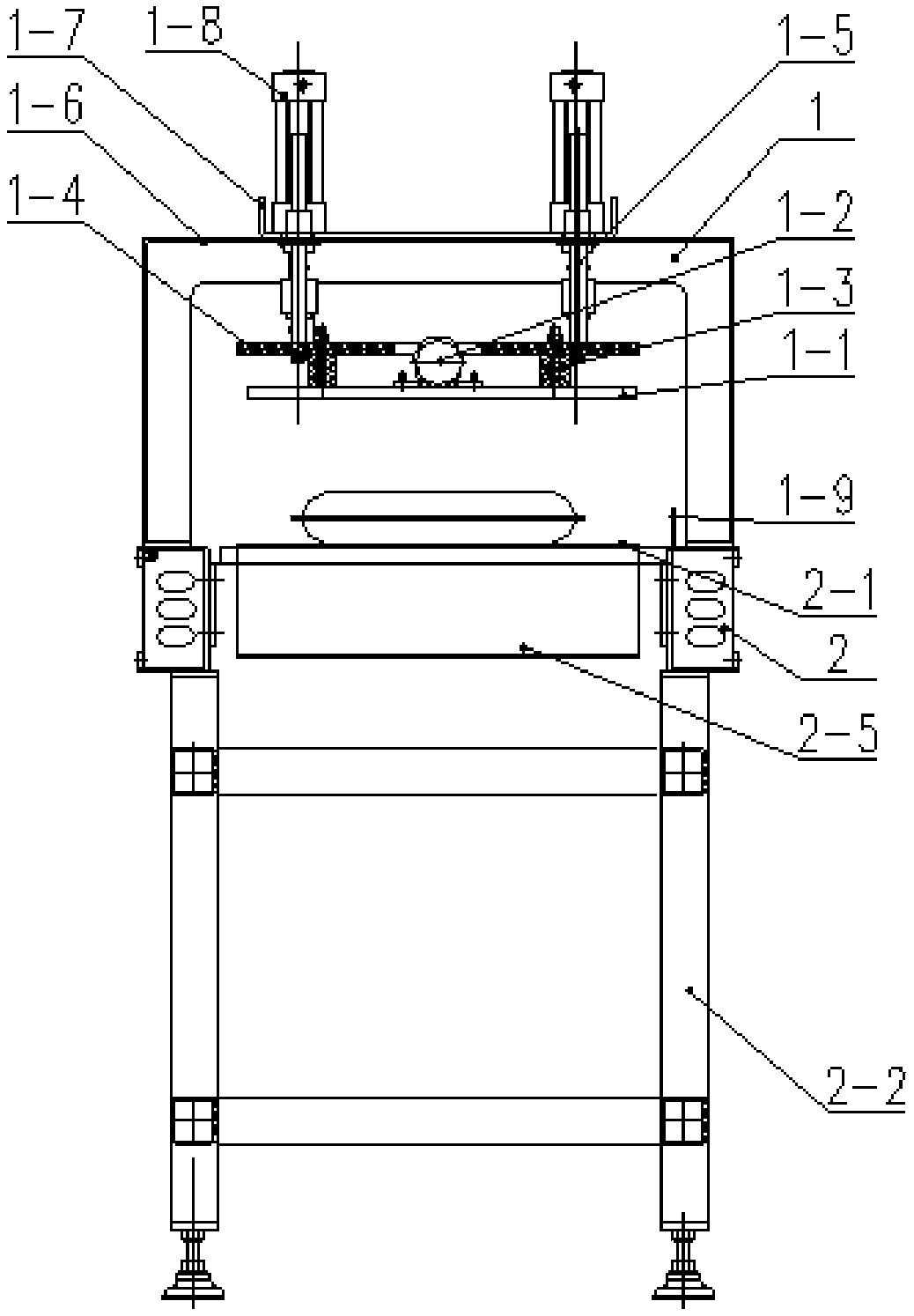

[0022] See attached picture.

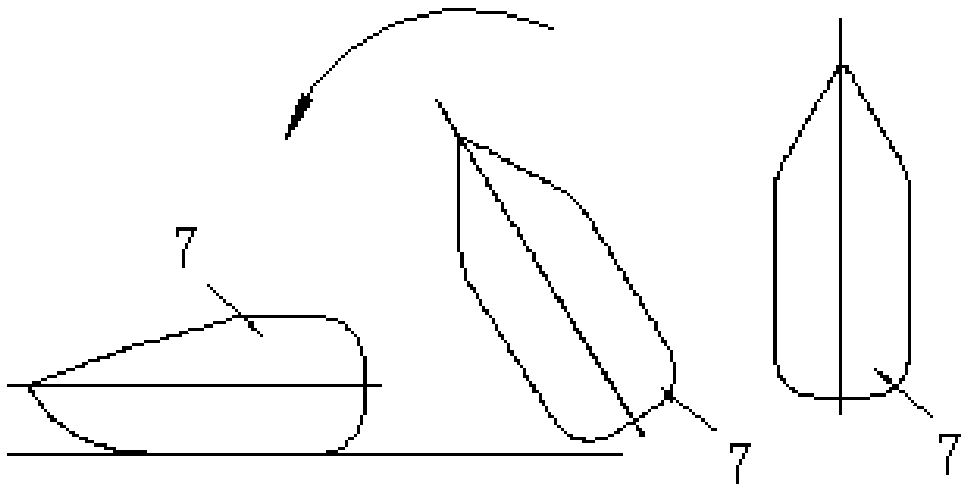

[0023] A vibratory flattening mechanism, characterized in that: it includes a conveyor 6, a leveling conveyor 2, and a vacuum conveyor 4 that are independent of each other and sequentially aligned for circular transportation, and the conveyor 6 is located at the feeder of the leveling conveyor 2 end, the vacuum conveyor 4 is located at the discharge end of the leveling conveyor 2, and the leveling machine 1 is erected above the leveling conveyor 2, and the leveling machine 1 includes a driving cylinder 1-8 driven Pressing plate 1-1, a vibration motor 1-2 is installed on the pressing plate 1-1, a vacuum mechanism 3 is erected above the vacuum conveyor 4, and the vacuum mechanism 3 includes a vacuum cover driven by a vacuum cylinder 3-3 3-1, a movable pressure plate 3-6 is installed inside the vacuum cover 3-1, and the pressure plate 3-6 is driven by a pressure cylinder 3-5 on the vacuum cover.

[0024] The conveyor 6, the leveling conveyor 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com