Smoke discharging mechanism of laser cutting machine

A laser cutting machine, the technology on the other side, applied in the directions of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of blockage of the suction fan, environmental pollution, inconvenient use, etc., to achieve convenient installation and disassembly, reduce environmental pollution, Avoid blocking the effect of the suction fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

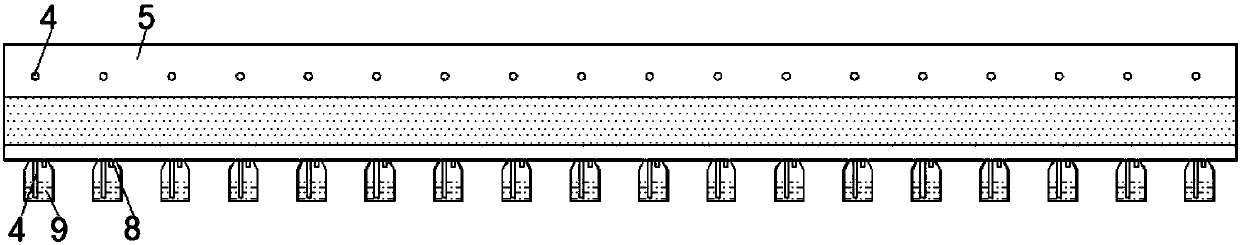

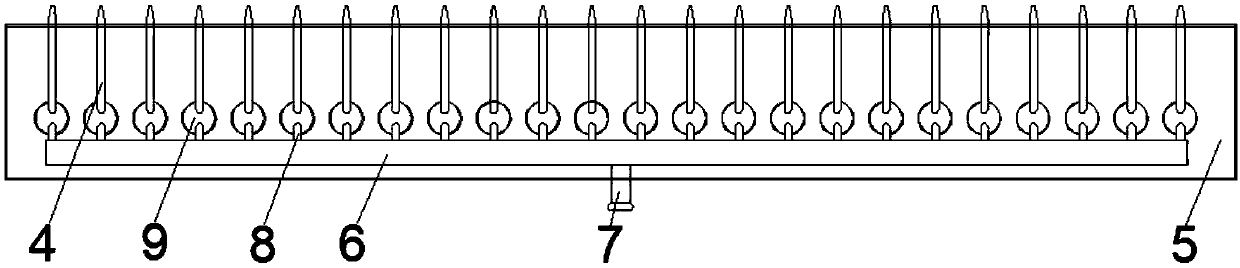

[0024] as attached figure 1 To attach Figure 4 Shown:

[0025] The invention provides a smoke exhaust mechanism of a laser cutting machine, which includes a blower fixing seat 1, an air inlet pipe 2, a blowing pipe 3, a No. 1 suction pipe 4, a suction fixing seat 5, a No. 3 suction pipe 6, a main suction Air pipe 7, No. 2 suction pipe 8 and purified water bottle 9; one side of the workbench is fixed with a blower fixing seat 1 by bolts; one side of the blower fixing seat 1 is embedded with an air inlet pipe 2; the air inlet pipe 2 One side of the workbench is connected with several blowing pipes 3, and the other side of the blowing pipes 3 protrudes outward from the other side of the blowing fixed seat 1; the other side of the workbench is fixed with a suction fixed seat 5 by bolts The main air suction pipe 7 is embedded in the air suction fixed seat 5 inboard from one side of the air suction fixed seat 5; one side of the main air suction pipe 7 is connected with a No. thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com