General die for conducting thermite welding on grounding grid

A general mold, aluminothermic welding technology, applied in the direction of aluminothermic welding equipment, welding equipment, manufacturing tools, etc., to achieve the effect of improving transportation convenience, saving production costs, and reducing connection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

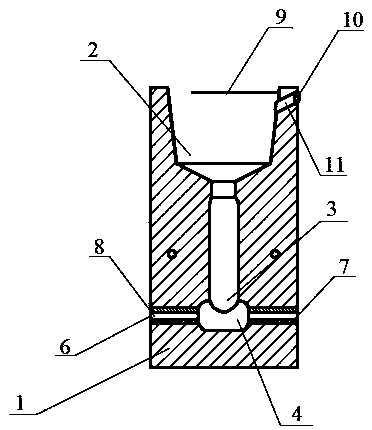

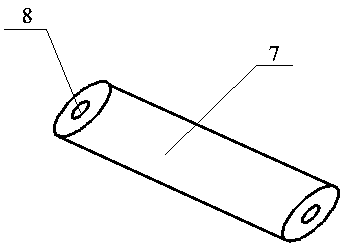

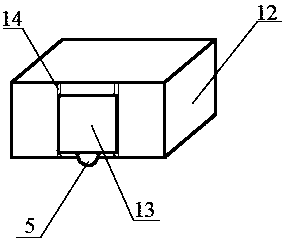

[0025] A general-purpose mold for aluminothermic welding of grounding grids, the general-purpose mold includes a mold body 1, and the inside of the mold body 1 is respectively arranged as a reaction chamber 2, a drainage groove 3, and a welding chamber 4 from top to bottom. The reaction chamber 2 is a structure with a wide top and a narrow bottom. The bottom of the reaction chamber 2 is connected with a drainage groove 3. A gasket is placed between the reaction chamber 2 and the drainage groove 3. A thermite can be placed above the gasket. Welding powder, ignition powder, the gasket can be an aluminum gasket, the fusion cavity 4 is horizontally located at the bottom of the drainage groove 3, and the horizontal sides of the outer surface of the mold body 1 are respectively provided with fixed placement cavities communicating with the fusion cavity 4 6. The fixed placement cavity 6 is provided with a detachable module 7, the module 7 is made of graphite, the diameter of the modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com