Magnetic separator

A magnetic separation and rack technology, applied in high gradient magnetic separators and other directions, can solve the problems affecting the normal operation of the equipment and the sorting efficiency, increasing the height of the feeding and discharging direction, and the high moisture content of the discharge material, so as to solve the problem of flushing. Good unloading effect, reduce waste of resources, and solve the sorting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

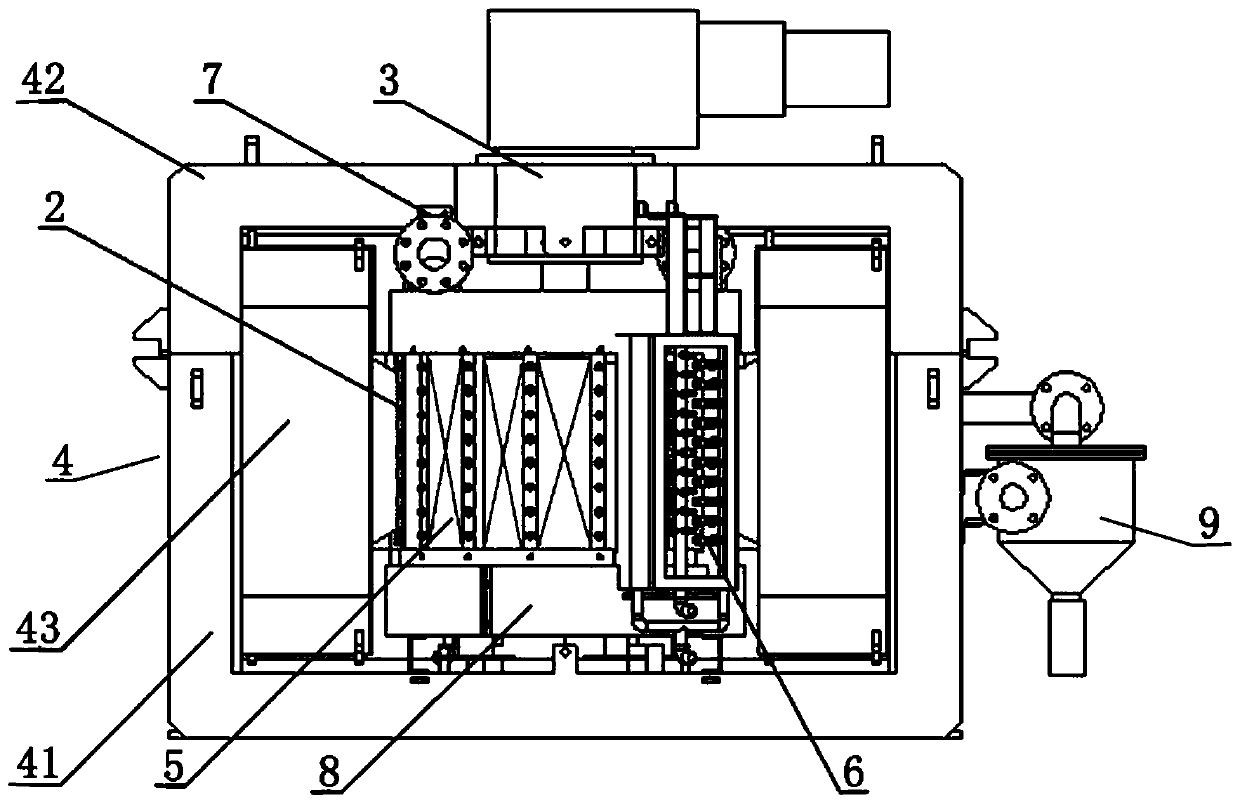

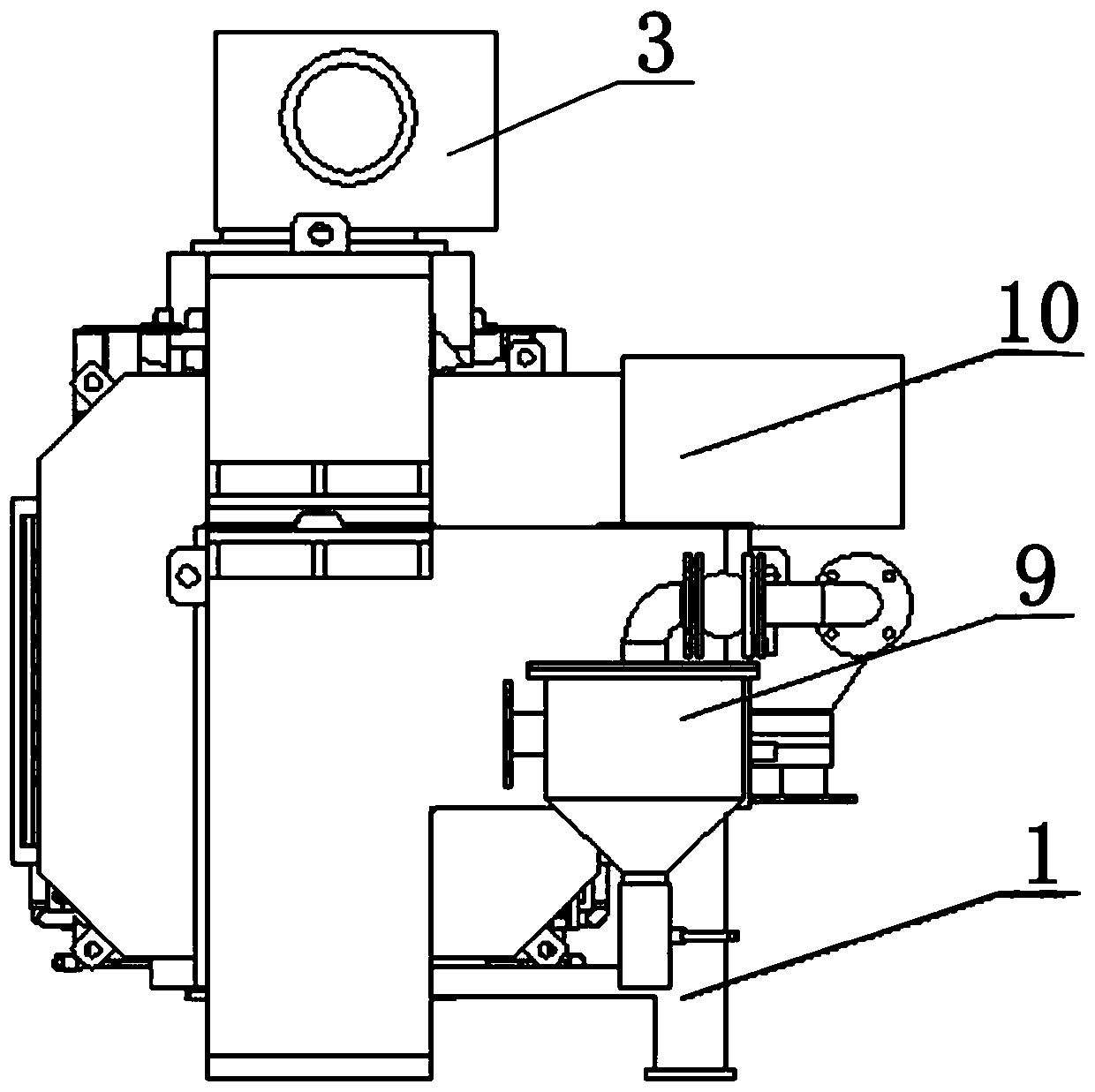

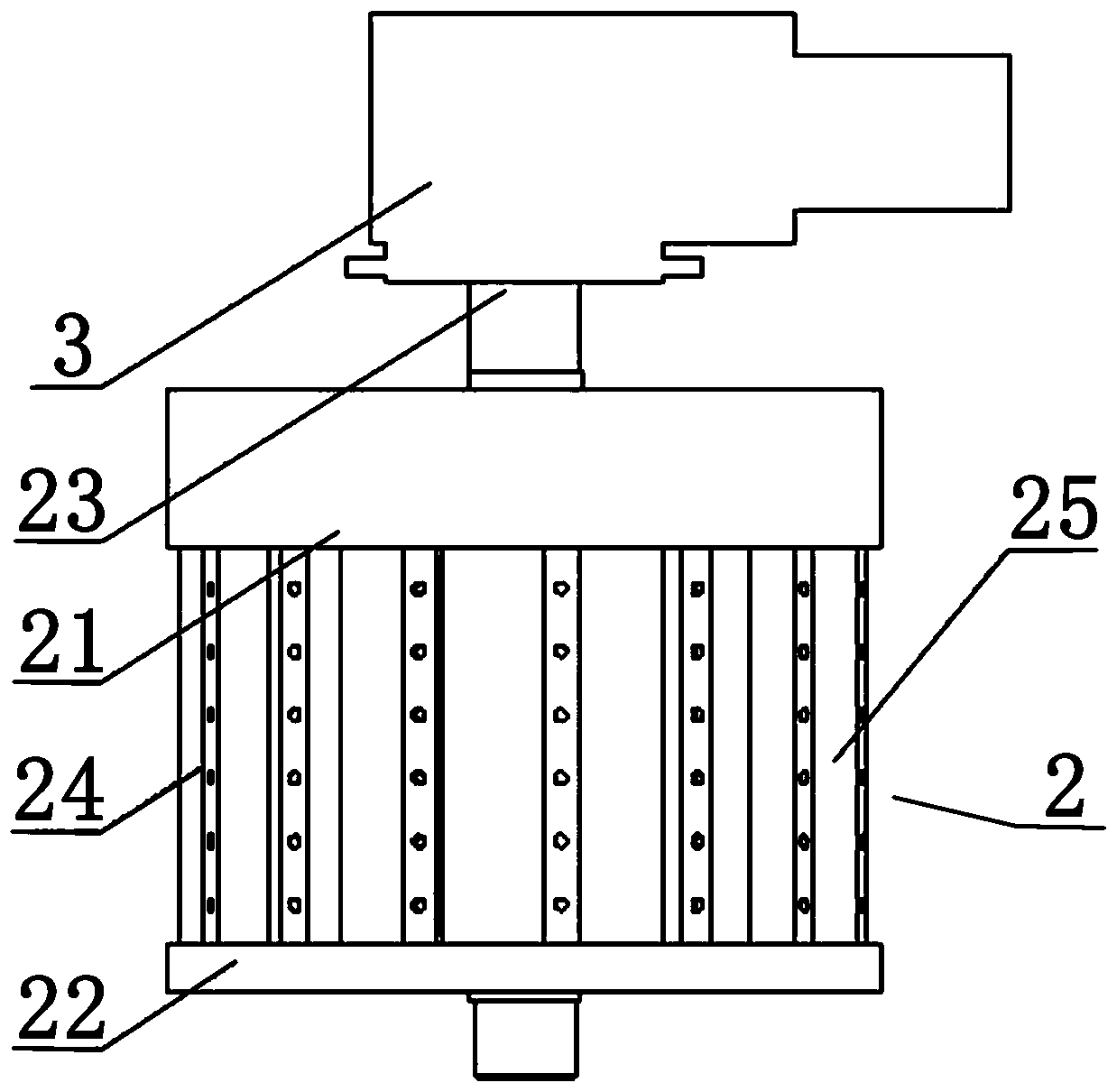

[0027] Such as Figure 1-Figure 7 As shown, the magnetic separator of the present invention includes a frame 1, a swivel 2, a horizontal rotation drive mechanism 3 and a magnetic field for generating a horizontal separation magnetic field and the magnetic field strength can reach a maximum of 1.8T. Excitation device 4. Wherein, the swivel 2 is provided with a mixed medium box 5, the thickness of the mixed medium box 5 along the flushing and discharging direction is between 10-600 mm, and its sorting height is between 20-3000 mm. Such as Figure 5 As shown, in this embodiment, the mixed medium box 5 is composed of a medium plate 51 and magnetically permeable stainless steel rods 52 and magnetically permeable stainless steel expanded mesh 53 mixedly arranged on the medium plate 51 along the separation height direction. Of course, the mixed medium box 5 can also be in other structural forms. For example, the mixed medium box 5 is composed of a medium plate and magnetically cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com