Accurate quantitative pesticide mixing tank

A technology for mixing tanks and pesticides, applied in mixers, mixers with rotating stirring devices, dissolving, etc., can solve the problems of waste of resources, production costs, and inability to ensure the degree of mixing, etc., to improve product quality, improve processing and testing efficiency, Effect of improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

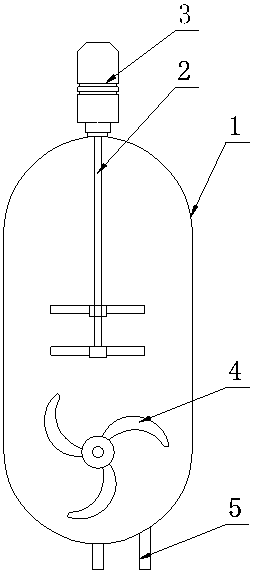

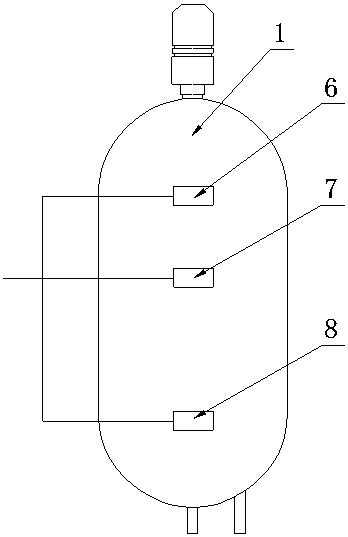

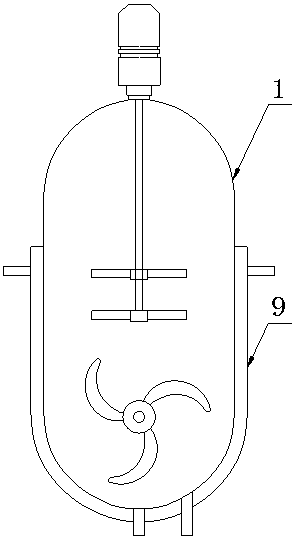

[0027] see Figure 1-2 , a quantitative and precise pesticide mixing tank, comprising a tank body 1, the inner upper part of the tank body 1 is provided with a stirring rod 2, the stirring rod 2 is connected to the stirring motor 3 on the top of the tank body 1, and the inner lower part of the tank body 1 is provided with an inlet The material disperser 4, the bottom of the tank body 1 is provided with a feed inlet 5, and the outside of the tank body 1 is provided with a liquid level detection system, the liquid level detection system includes a space measurement probe 6 installed on the outer wall of the tank body 1, a quantitative measurement probe 7 and the low-level measurement probe 8, the vacancy measurement probe 6, the quantitative measurement probe 7 and the low-level measurement probe 8 are all connected to the outside control host.

[0028] Preferably, the tank body 1 has a cylindrical shape as a whole, and the top and bottom are hemispherical, and the empty space m...

Embodiment 2

[0040] The feeding disperser 4 includes a shaft sleeve and arc-shaped plates, three arc-shaped plates are evenly distributed on the outer periphery of the shaft sleeve, and the shaft sleeve is sleeved on the output shaft of the dispersion drive motor. The decentralized drive motor is installed outside the tank body 1 .

Embodiment 3

[0042] Feeding disperser 4 is provided with several, evenly installed on the output shaft of the dispersing drive motor

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com