Composition eliminating hazardous substances in cigarette or air and application of composition

A technology of harmful substances and compositions, applied in the field of air purification, can solve the problems of no disclosure of toxic substances, low practicability, poor efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

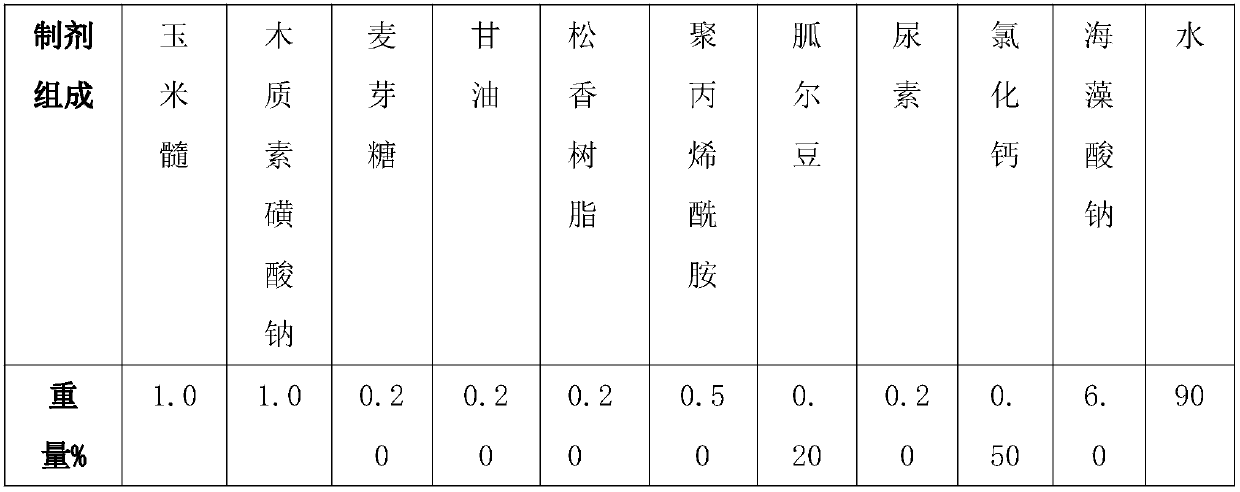

[0069] Example 1: First prepare the reagent according to the weight ratio indicated in Table 1 below; then mix it with the metal-organic framework material MOF-177 at a weight ratio of 1:5, and place it in a desiccator connected to a vacuum pump. Vacuum under sealed conditions for 10 minutes to form a sufficient negative pressure, cut off the connection with the vacuum pump. The obtained product was transferred out of the desiccator, wrapped in filter paper until the surface was dry.

[0070] Table 1

[0071] Preparation composition

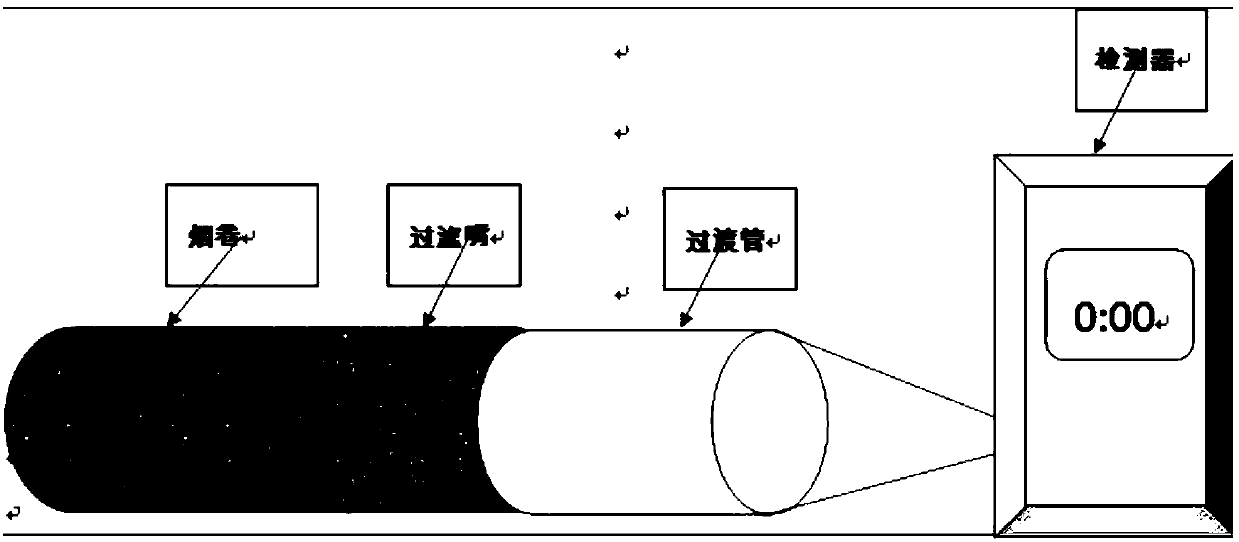

[0072] Weigh about 0.05 g of the surface-dried powder product, place it evenly on the interface between the cigarette and the filter tip and reseal it. Then one end of the filter tip is inserted into the transition tube and sealed, and the other end of the transition tube is connected with the air inlet of the air particle detector and sealed. The principle of this type of particle detector is based on measuring the concentration of p...

Embodiment 2

[0073] Example 2: First prepare the reagent according to the weight ratio indicated in Table 2 below; then mix it with the metal-organic framework material FE-BTC at a weight ratio of 1:5, and place it in a desiccator connected to a vacuum pump. Vacuum under sealed conditions for 10 minutes to form a sufficient negative pressure, cut off the connection with the vacuum pump. The obtained product was transferred out of the desiccator, wrapped in filter paper until the surface was dry.

[0074] Table 2

[0075] Preparation composition

[0076]Weigh about 0.05 g of the surface-dried powder product, place it evenly on the interface between the cigarette and the filter tip and reseal it. Then one end of the filter tip is inserted into the transition tube and sealed, and the other end of the transition tube is connected with the air inlet of the air particle detector and sealed. The principle of this type of particle detector is based on measuring the concentration of par...

Embodiment 3

[0077] Example 3: First prepare the reagent according to the weight ratio indicated in Table 3 below; then mix it with the metal-organic framework material MIL-53 at a weight ratio of 1:5, and place it in a desiccator connected to a vacuum pump. Vacuum under sealed conditions for 10 minutes to form a sufficient negative pressure, cut off the connection with the vacuum pump. The obtained product was transferred out of the desiccator, wrapped in filter paper until the surface was dry.

[0078] table 3

[0079] Preparation composition

[0080] Weigh about 0.05 g of the surface-dried powder product, place it evenly on the interface between the cigarette and the filter tip and reseal it. Then one end of the filter tip is inserted into the transition tube and sealed, and the other end of the transition tube is connected with the air inlet of the air particle detector and sealed. The principle of this type of particle detector is based on measuring the concentration of pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com