Transformer station pressboard anti-error operation method and device

A technology for preventing misoperations and substations, applied in circuit devices, electrical components, information technology support systems, etc., can solve problems such as the inability to monitor the state of the pressure plate in real time, affect the safe operation of the power grid, and improve the management efficiency of the pressure plate , prevent mis-injection and mis-return, and ensure the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] refer to figure 1 , figure 1 It shows the implementation flow of the substation pressure plate anti-misoperation method provided by Embodiment 1 of the present invention, wherein the pressure plate includes a soft pressure plate and a hard pressure plate, and the method is described in detail as follows:

[0034] S101: Receive the status information of the soft press plate sent by the monitoring system and the status information of the hard press plate sent by the intelligent anti-malfunction device.

[0035] Among them, the soft pressure plate refers to the switching on and off of a certain function of the software system, such as switching on and off a certain protection and control function. The change of the throwing and withdrawing state of the soft pressure plate is usually realized by modifying the software control word protected by the microcomputer. The monitoring system can monitor the state of the soft pressing plate, and the device obtains the state inform...

Embodiment 2

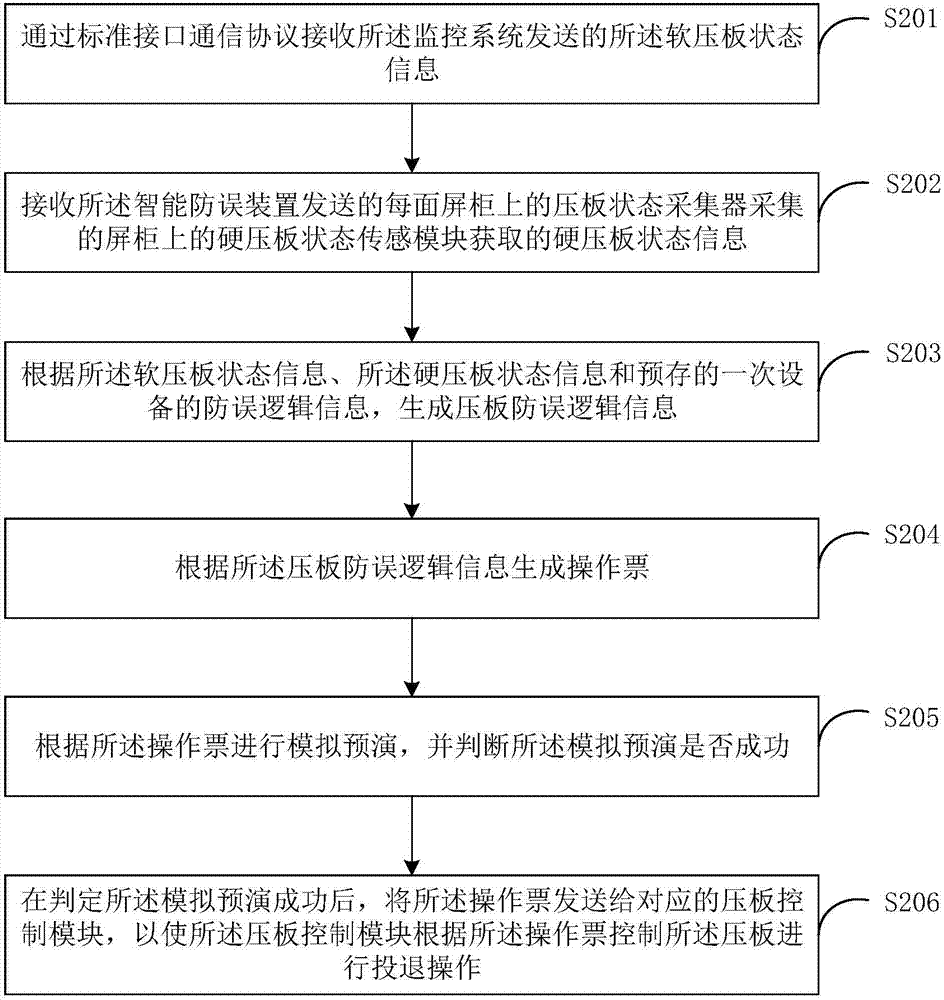

[0049] refer to figure 2 , figure 2 It shows the implementation process of the method for preventing misoperation of substation pressure plate provided by the second embodiment of the present invention. On the basis of the foregoing embodiments, the embodiments of the present invention are described in detail as follows:

[0050] S201: Receive the soft platen status information sent by the monitoring system through a standard interface communication protocol.

[0051] Specifically, the device establishes a communication connection with the monitoring system through the RS232 interface, and according to the communication protocol of the monitoring system, a corresponding communication protocol is designed to realize data transmission.

[0052] S202: Receive the hard press plate state information collected by the press plate state collector on each panel cabinet and acquired by the hard press plate state sensing module on the screen cabinet sent by the intelligent error prev...

Embodiment 3

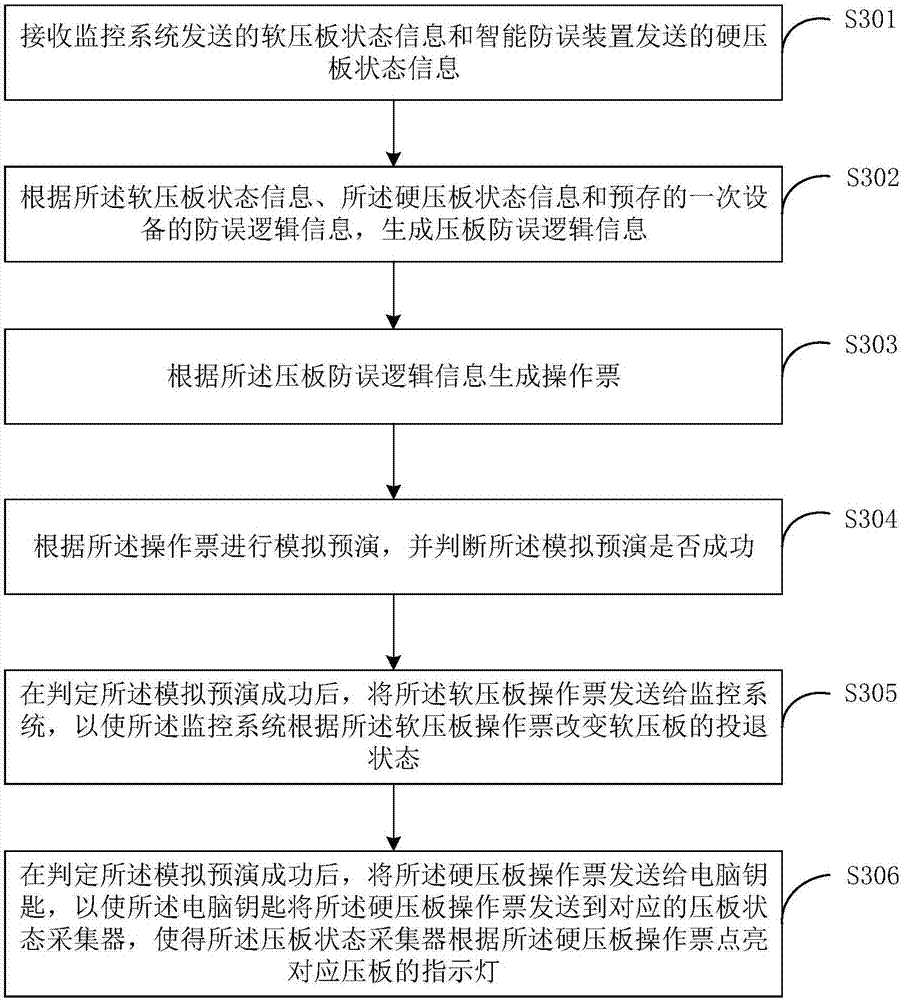

[0065] refer to image 3 , image 3 It shows the implementation flow of the method for preventing misoperation of the substation pressure plate provided by the third embodiment of the present invention. On the basis of the foregoing embodiments, the embodiments of the present invention are described in detail as follows:

[0066] Steps S301 to S304 are consistent with the above S101 to S104, please refer to the relevant description of S101 to S104 for specific content, and will not be repeated here.

[0067] S305: After determining that the simulation rehearsal is successful, send the soft press plate operation ticket to the monitoring system, so that the monitoring system changes the soft press plate throw-in and withdrawal status according to the soft press plate operation ticket.

[0068] Specifically, the device establishes a communication connection with the monitoring system through the RS232 interface, and according to the communication protocol of the monitoring syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com