Manufacturing method for mulberry paper molded object

A manufacturing method and technology of mulberry paper, applied in textiles and paper making, etc., can solve the problems of environmental pollution, ecological environment damage, destruction of natural ecological environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

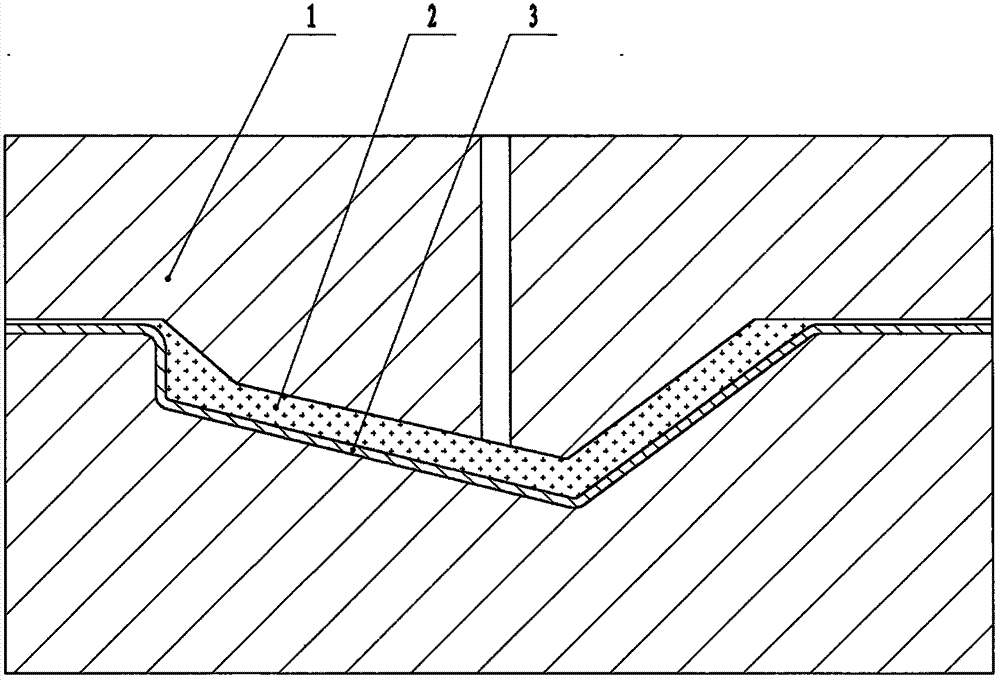

Image

Examples

Embodiment Construction

[0019] A kind of manufacture method of mulberry paper molding, comprises the following steps:

[0020] (1) material preparation: after taking the bark from the mulberry tree, put the mulberry bark into the pot for cooking, put the mulberry bark into the pot and cook until it is boiled so that it can be beaten thoroughly;

[0021] (2) beating: after the mulberry bark after cooking is cleaned, beat repeatedly, repeatedly beating is to decompose the mulberry bark into mulberry fiber as much as possible to facilitate molding needs;

[0022] (3) Dipping: after beating, mulberry bark is soaked in mulberry gum until forming a mulberry fiber material containing moisture. The mulberry gum is dropped into water and mixed into the first process, and the mulberry bark is dropped into water and mixed into the second process. In the second process, the water containing mulberry bark is put into the mulberry gum water of the first process and mixed with mulberry fiber to form the third proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com