Clamping device of substrate, film formation device, and substrate mounting device and method

A film forming method and substrate holding technology, which is applied in the direction of ion implantation plating, coating, electrical components, etc., can solve the problems of film blurring, mask and substrate adhesion reduction, etc., and achieve the effect of preventing position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

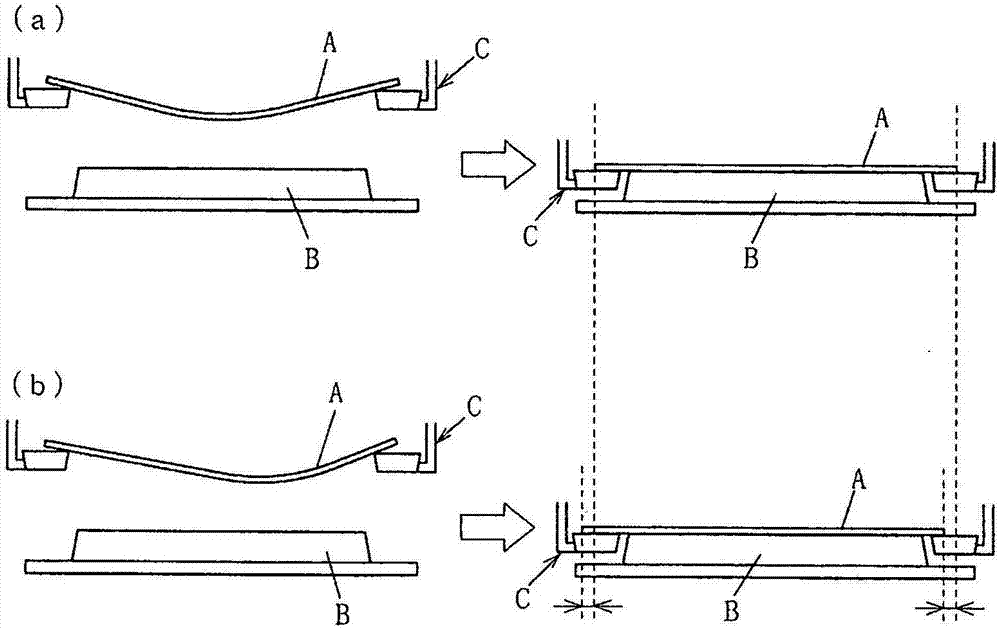

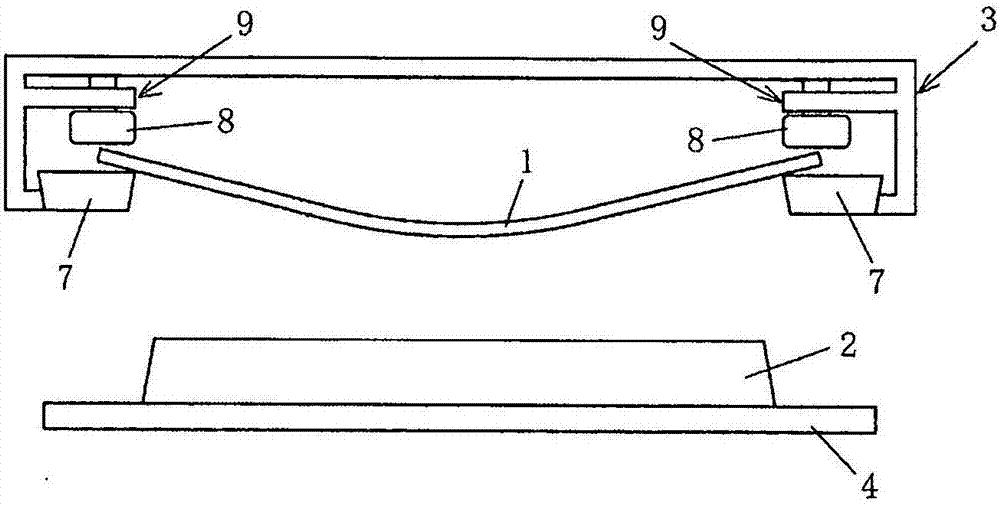

[0032] In the present embodiment, the substrate 1 is lowered and brought into contact with the substrate 1 in a state in which the outer peripheral portion of the substrate 1 is tentatively clamped by the pressing force 8 abutting against the substrate 1 and causing a displacement of the substrate holder 3 . The mask 2 is further lowered to place the substrate 1 on the mask 2 . Thereafter, the pressing force of the pressing tool 8 is set to a stronger pressing force to such an extent that no positional displacement occurs with respect to the substrate holder 3 , and the substrate 1 is actually clamped.

[0033] At this time, at least at the beginning of the contact, the position deviation of the substrate 1 relative to the substrate holder 3 accompanying the contact with the mask 2 is allowed, so the substrate 1 bends due to its own weight and the central part of the substrate 1 comes into contact with the mask 2 in advance. The generated deformation is not hindered, and the o...

Embodiment 1

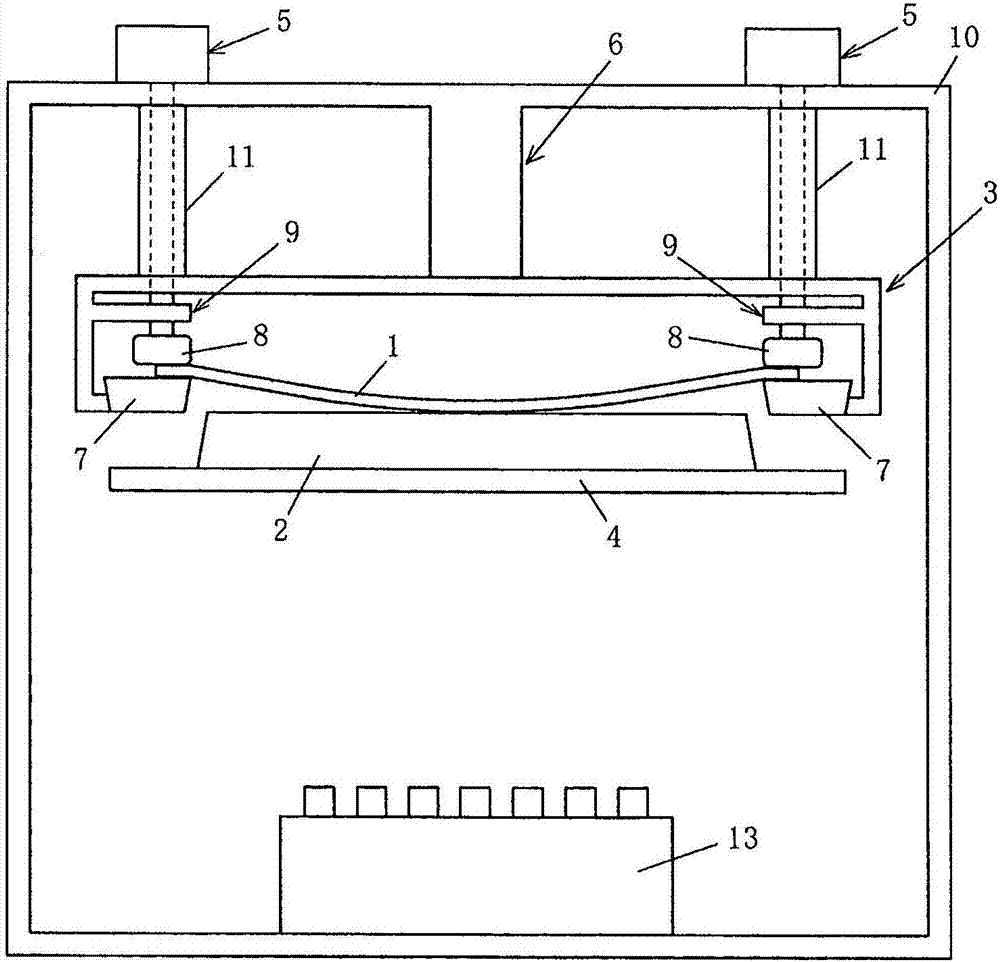

[0038] This embodiment is an example of applying the present invention in a film forming device, such as figure 2 As shown in the figure, in this film forming apparatus, a substrate 1 and a mask 2 are placed in a vacuum chamber 10 and a film is formed using a film forming mechanism including an evaporation source 13 and the like. The film forming device is provided with: a film thickness monitor, which monitors the evaporation rate of the evaporated particles emitted from the evaporation source 13; a film thickness gauge, which is arranged outside the vacuum chamber 10, and converts the amount of monitored evaporated particles into film thickness ; and a power supply for the heater to heat the evaporation source 13 in order to control the evaporation rate of the film-forming material so that the converted film thickness becomes a desired film thickness; and the like. For example, this film-forming apparatus is used in the manufacture of a display panel for an organic electrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com