A kind of floating bed and preparation method thereof

A floating bed and square plate technology, which is applied in the field of floating beds, can solve the problems of poor wind and wave impact resistance, easy sinking and plugging holes at the bottom, and achieve the effects of reducing density, preventing sinking or uneven coating, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

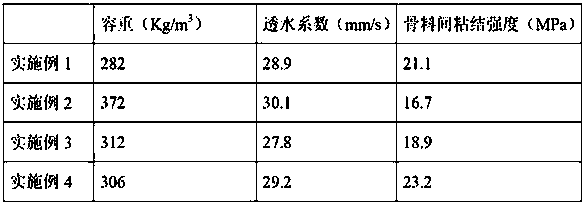

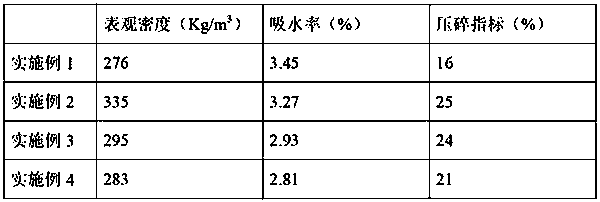

Examples

Embodiment 1

[0023] A kind of preparation method of floating bed, comprises the following steps:

[0024] (1) Mix 30 parts by mass of pear residue and 10 parts of water for 2 minutes, then add 15 parts by weight of cement and 10 parts of foaming agent and mix evenly to obtain aggregate slurry.

[0025] (2) Make the aggregate slurry into a square plate with a thickness of 3cm, keep the square plate at 60°C for 1 hour, and then maintain it at 3MPa for 4 hours.

[0026] (3) Cut the cured square plate into a rhombic dodecahedron with a side length of 3 cm to obtain an aggregate body.

[0027] (4) Evenly mix 50 parts by weight of cement, 10 parts of epoxy resin and 10 parts of water to obtain a surface layer slurry.

[0028] (5) Blow to the aggregate body with an air pressure of 2MPa from bottom to top to ensure that the aggregate body rotates continuously during the falling process, and at the same time use a cyclone blower to spray the surface layer slurry to the aggregate body with an air p...

Embodiment 2

[0032] Another kind of preparation method of floating bed, comprises the following steps:

[0033] (1) First mix 10 parts by mass of pear pomace and 5 parts of water for 0.5 minutes, then add 2 parts by weight of cement and 5 parts of foaming agent and mix evenly to obtain an aggregate slurry.

[0034] (2) Make the aggregate slurry into a square plate with a thickness of 1cm, keep the square plate at 40°C for 1 hour, and then maintain it at 1MPa for 4 hours.

[0035] (3) Cut the cured square plate into a rhombic dodecahedron with a side length of 1 cm to obtain an aggregate body.

[0036] (4) Evenly mix 20 parts by weight of cement, 2 parts of epoxy resin and 5 parts of water to obtain a surface layer slurry.

[0037] (5) Blow to the aggregate body with an air pressure of 0.5MPa from bottom to top to ensure that the aggregate body rotates continuously during the falling process, and at the same time use a cyclone blower to spray the surface slurry to the aggregate from the si...

Embodiment 3

[0041] Another kind of preparation method of floating bed, comprises the following steps:

[0042] (1) First mix 20 parts by mass of pear pomace and 8 parts of water for 1 minute, then add 10 parts by weight of cement and 7 parts by weight of foaming agent and mix evenly to obtain an aggregate slurry.

[0043] (2) Make the aggregate slurry into a square plate with a thickness of 2cm, keep the square plate at 50°C for 1 hour, and then maintain it at 2MPa for 4 hours.

[0044] (3) Cut the cured square plate into a rhombic dodecahedron with a side length of 2 cm to obtain an aggregate green body.

[0045] (4) Evenly mix 35 parts by weight of cement, 6 parts of epoxy resin and 8 parts of water to obtain a surface layer slurry.

[0046] (5) Blow to the aggregate body with an air pressure of 1 MPa from bottom to top to ensure the continuous rotation of the aggregate body during the falling process, and at the same time use a cyclone blower to spray the surface layer slurry to the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com