Intelligent maintenance cart for capacitor production

An intelligent and capacitive technology, applied in the field of capacitors, can solve the problems of large wear and leakage of equipment, and achieve the effect of reasonable structure, monitoring equipment operation status, and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

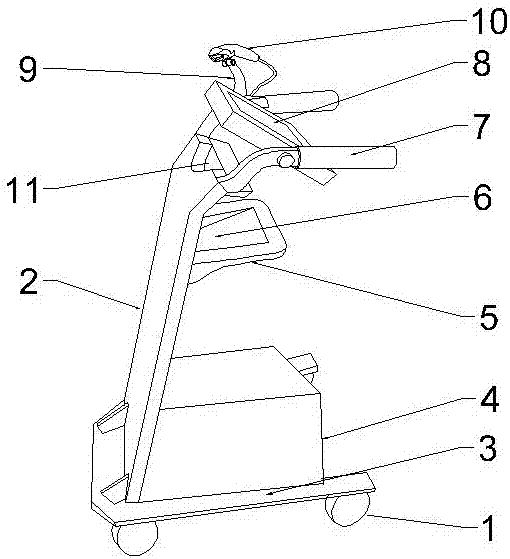

[0015] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 , the intelligent maintenance trolley for capacitor production described in the present embodiment includes a vehicle frame 2 with traveling wheels 1, a storage plate 3 is provided on the rear side of the bottom of the vehicle frame 2, and a tool box 4 is placed on the storage plate 3. The middle part of the vehicle frame 2 above the box 4 is provided with a maintenance platform 5, and the center of the maintenance platform 5 is provided with a concave placement groove 6, and the rear side of the top of the vehicle frame 2 is provided with a push handle 7, and the front ends of the two push handles 7 are movable and hinged. There is a display screen 8, and the display screen 8 is movably hinged between two push handles 7 through adjusting bolts, one of which is equipped with a gun holder 9, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com