Composite fire extinguishing patch and preparation method thereof

A technology of patch and fire extinguishing agent, applied in fire protection equipment and other directions, can solve the problem of low fire extinguishing sensitivity of fire extinguishing materials, and achieve the effect of good insulation performance, good insulation, and protection of life and property safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

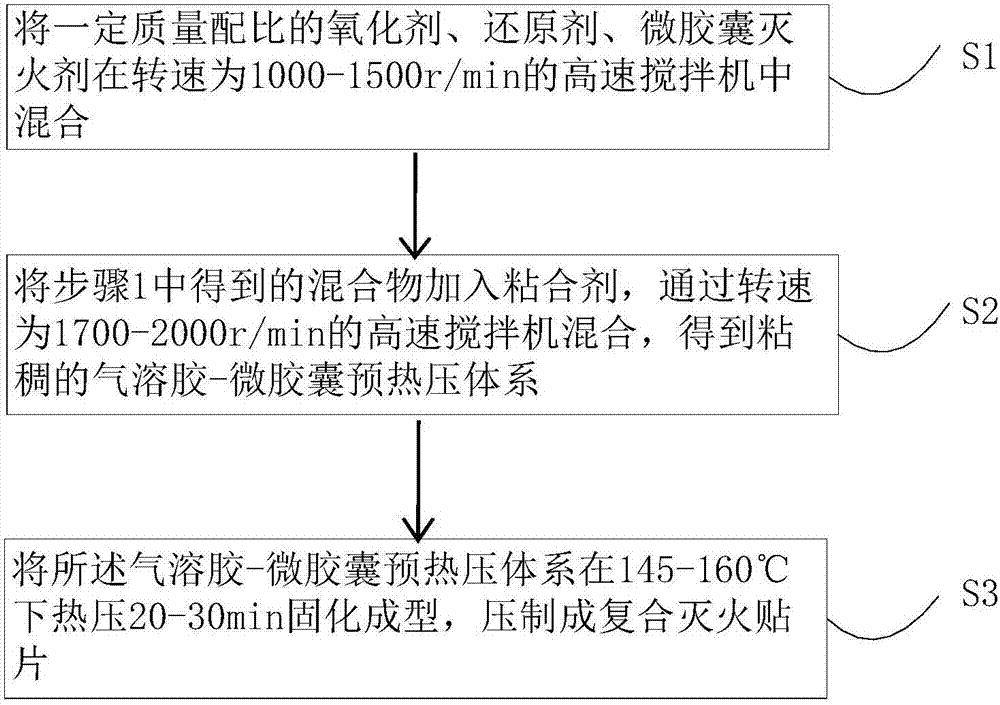

Method used

Image

Examples

Embodiment 1

[0036]Both are 10 parts of 230 mesh potassium nitrate and 50 parts of strontium nitrate, 5 parts of 270 mesh reducing agent and 30 parts of 80 mesh microcapsule fire extinguishing agent, mix in a high-speed mixer with a rotation speed of 1000-1500r / min, and add adhesive after mixing 50 parts, wherein, epoxy resin accounts for 55% of the mass fraction of adhesive, m-phenylenediamine accounts for 1% of the mass fraction of adhesive, acetone accounts for 44% of the mass fraction of adhesive, and then the speed of passing through is 1700- 2000r / min high-speed mixer mixed evenly to obtain a viscous aerosol-microcapsule preheating press system, and the aerosol-microcapsule preheating press system was cured at 145°C for 20 minutes, and pressed into a 1.0mm Composite fire extinguishing patch, when used, it should be covered with Nitto 500 or 3M 9495LE double-sided adhesive on one side.

Embodiment 2

[0038] All are 13 parts of 240 mesh potassium nitrate and 53 parts of strontium nitrate, 6 parts of 290 mesh reducing agent and 33 parts of 90 mesh microcapsule fire extinguishing agent, mix in a high-speed mixer with a rotation speed of 1000-1500r / min, and add adhesive after mixing 53 parts, wherein, epoxy resin accounted for 57% of the mass fraction of adhesive, m-phenylenediamine accounted for 1.2% of the mass fraction of adhesive, acetone accounted for 41.8% of the mass fraction of adhesive, and then passed through the rotating speed of 1700- 2000r / min high-speed mixer mixed evenly to obtain a viscous aerosol-microcapsule preheating press system, and the aerosol-microcapsule preheating press system was cured at a temperature of 150°C for 23 minutes, and pressed to 1.0mm The composite fire extinguishing patch, when used, should be covered with Nitto 500 or 3M 9495LE double-sided adhesive on one side.

Embodiment 3

[0040] 14 parts of 260-mesh potassium nitrate and 54 parts of strontium nitrate, 7 parts of 300-mesh reducing agent and 35 parts of 110-mesh microcapsule fire extinguishing agent are mixed in a high-speed mixer with a rotation speed of 1000-1500r / min, and the adhesive is added after mixing 55 parts, wherein, epoxy resin accounts for 60% of the mass fraction of adhesive, m-phenylenediamine accounts for 1.5% of the mass fraction of adhesive, acetone accounts for 38.5% of the mass fraction of adhesive, and then the speed of passing through is 1700- 2000r / min high-speed mixer mixed evenly to obtain a viscous aerosol-microcapsule preheating press system, and the aerosol-microcapsule preheating press system was hot-pressed at 155°C for 27 minutes to be solidified and pressed to 1.0mm The composite fire extinguishing patch, when used, should be covered with Nitto 500 or 3M 9495LE double-sided adhesive on one side.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com