Carding machine and fitting for a carding machine

A carding machine and carding machine technology, applied in fiber treatment, deburring devices, textiles and papermaking, etc., can solve the problems of lifting and maintaining unfavorable fiber materials, poor carding effect, etc., and achieve the effect of reducing agglomeration and optimizing cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

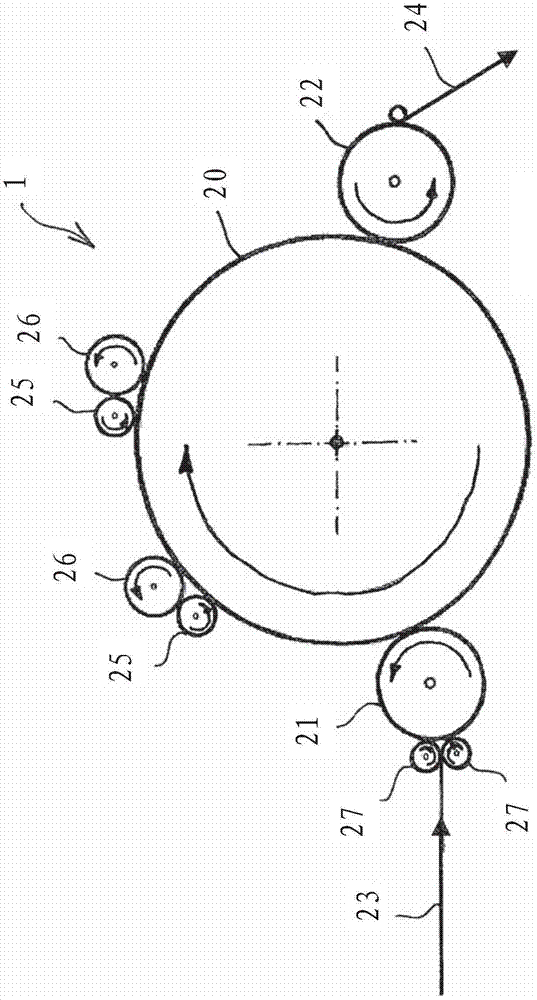

[0023] exist figure 1 A schematic diagram of a carding machine 1 is shown in FIG. 2 , and said carding machine 1 has a main cylinder 20 on which a card clothing with a toothed wire according to the invention is mounted in a manner not shown in detail.

[0024] The licker-in roller 21 cooperates with the main cylinder 20 and conveys the fiber raw material 23 to the licker-in roller 21 via the feed roller 27 . A plurality of stripping rollers 25 and associated working rollers 26 are arranged distributed over the circumference of the main cylinder 20 . The formed web 24 is removed from the main cylinder 20 via a stripping roller 22 .

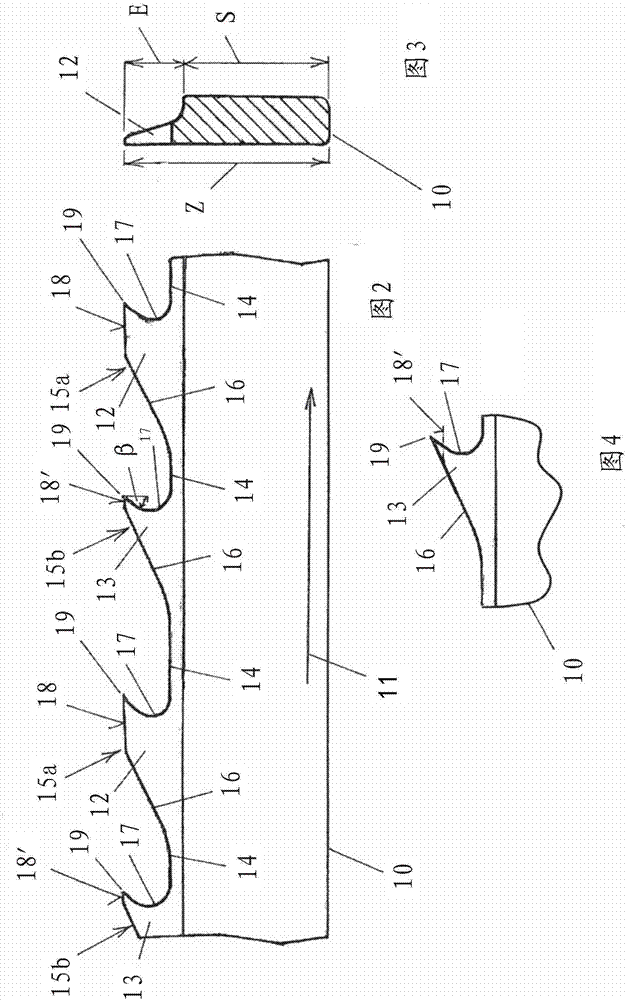

[0025] Use the following figure 2 , image 3 with Figure 4 The described card clothing can be arranged on the main cylinder 20, on the licker-in roller 21 and optionally also on the stripping roller 25, the working roller 26 and the stripping roller 22, wherein the card 1 is only shown as an example And the card clothing according to the inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com