Method and device for measuring acting force of solid particles on silo

A measuring device and technology for solid particles, applied in the direction of measuring force components, etc., can solve problems such as limited application range of methods, inaccurate calculation results, plastic deformation of silos, etc. The effect of low cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

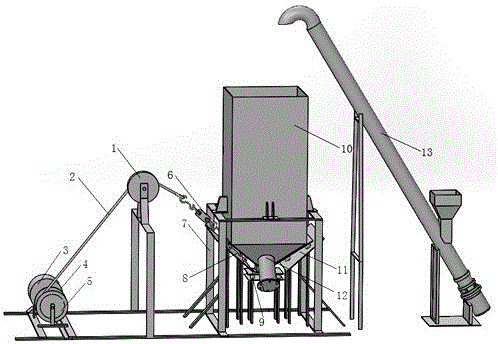

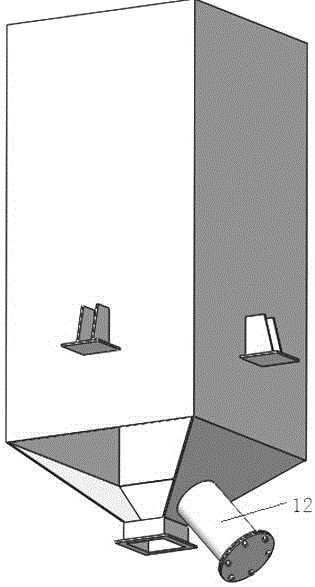

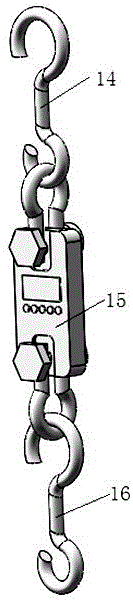

[0024] like figure 1 shown, as figure 1 The device for measuring the force of the solid granular material of the present invention on the silo is composed of a fixed pulley 1, a steel wire rope 2, a motor 3, a reducer 4, a rope winding wheel 5, a funnel wall tangential force gauge 6, and a silo support Frame 7, funnel wall tangential force measuring member 8, bin bottom positive pressure measuring device 9, silo 10, funnel wall normal force measuring device 11, discharge bypass 12, and screw feeder 13 constitute. like figure 2 In the silo 10 shown, the funnel wall on one side of the bottom is equipped with a discharge bypass 12, and the funnel walls on the adjacent two sides are arranged for the funnel wall tangential force measuring device 8 and the funnel wall normal force measuring device 11. remove. like image 3 The shown funnel wall tangential force dynam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com