Shaped external-hanging-bracket protective system and installation method

A protection system and stereotyped technology, which is applied to the attachment of scaffolding, scaffolding supported by housing structures, and housing structure support, etc., can solve the problems of large labor consumption, poor protection effect, inconvenient operation and turnover, etc., and achieves time-consuming disassembly. The effect of less, convenient setting and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

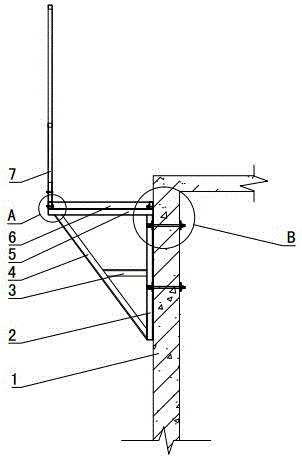

[0042] Such as Figure 1~3 Shown: The prefabricated exterior wall 1 is provided with reserved holes matching the support frame, and each support frame corresponds to two reserved holes, and the two reserved holes corresponding to the same support frame are located in the same vertical plane . Two supporting frames are installed on the lower side of each operating platform 6, and the two supporting frames are respectively arranged at the two ends of the two operating platforms 6, and the operating platform 6 is placed on the two supporting frames and is detachably connected with the supporting frames .

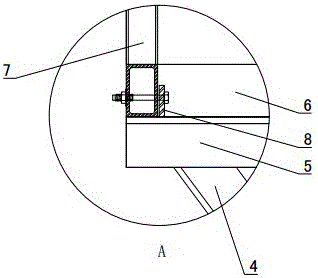

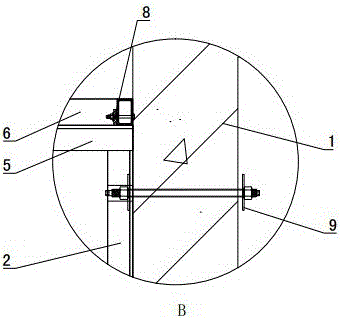

[0043]The support frame includes a vertical fixed rod 2, a cross beam 5 and a diagonal brace 4. The longitudinal fixed rod 2, the cross beam 5 and the diagonal brace 4 are all 8# channel steel. The vertical fixed rod 2 is arranged vertically, and the cross beam 5 is arranged horizontally. It is fixedly connected with the upper end of the longitudinal fixed rod 2, the upper en...

Embodiment 2

[0064] The difference between Embodiment 2 and Embodiment 1 is that the installation method includes the following steps:

[0065] (1) The prefabricated exterior wall 1 is hoisted and installed, and the prefabricated exterior wall 1 is provided with reserved holes for connecting with the support frame;

[0066] The prefabricated exterior wall 1 is hoisted, and the prefabricated exterior wall 1 is positioned and assembled according to the engineering drawing. The prefabricated exterior wall 1 is provided with reserved holes for fixed connection with the support frame.

[0067] (2) Assemble the support frame, operating platform 6 and protective frame 7 into a protective device, and fixedly connect the operating platforms 6 of adjacent protective devices, and fixedly connect the protective frames 7 of adjacent protective devices to form a protective system;

[0068] Weld the triangular support frame, and assemble the support frame, the protective platform 6 and the protective fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com