A friction type overload automatic shedding sling

An automatic shedding, friction-type technology, applied in the direction of load hanging components, transportation and packaging, safety devices, etc., can solve problems such as wire rope breakage, heavy objects falling, and inaccurate estimates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

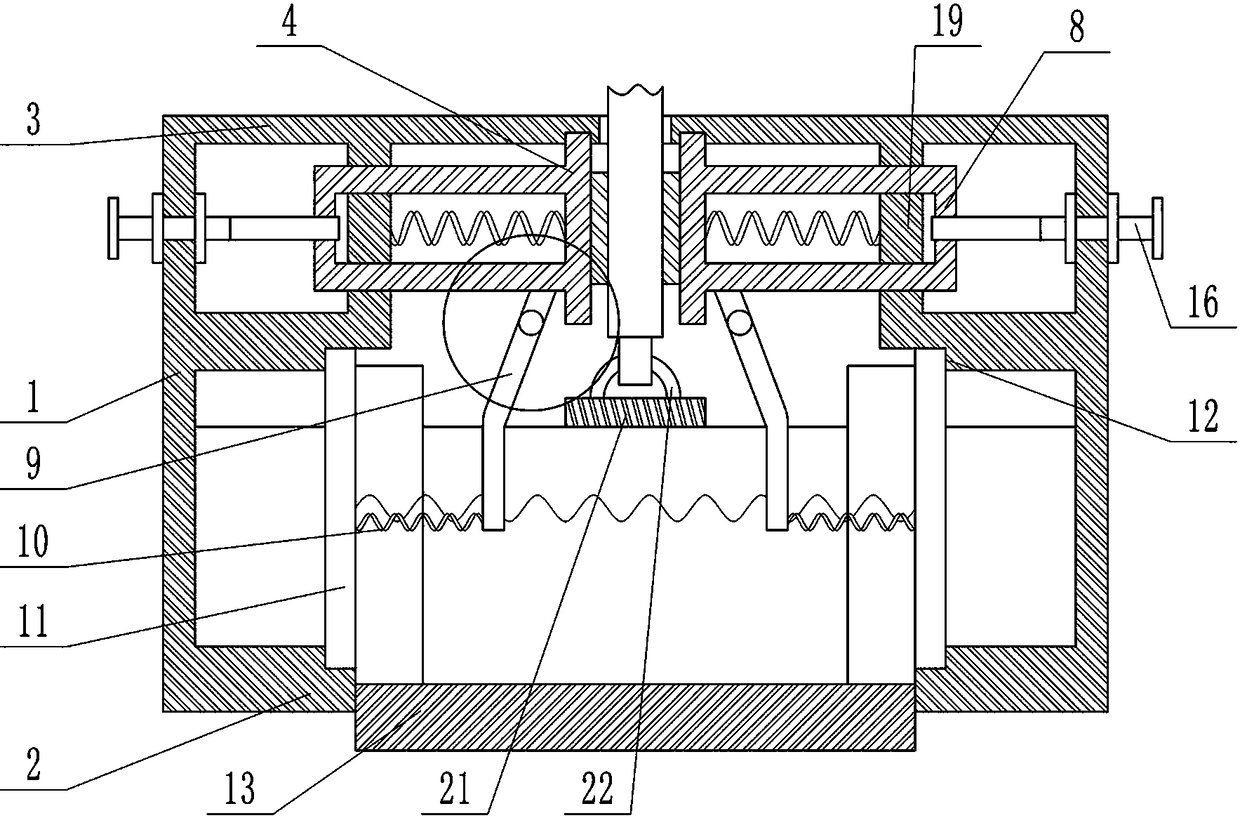

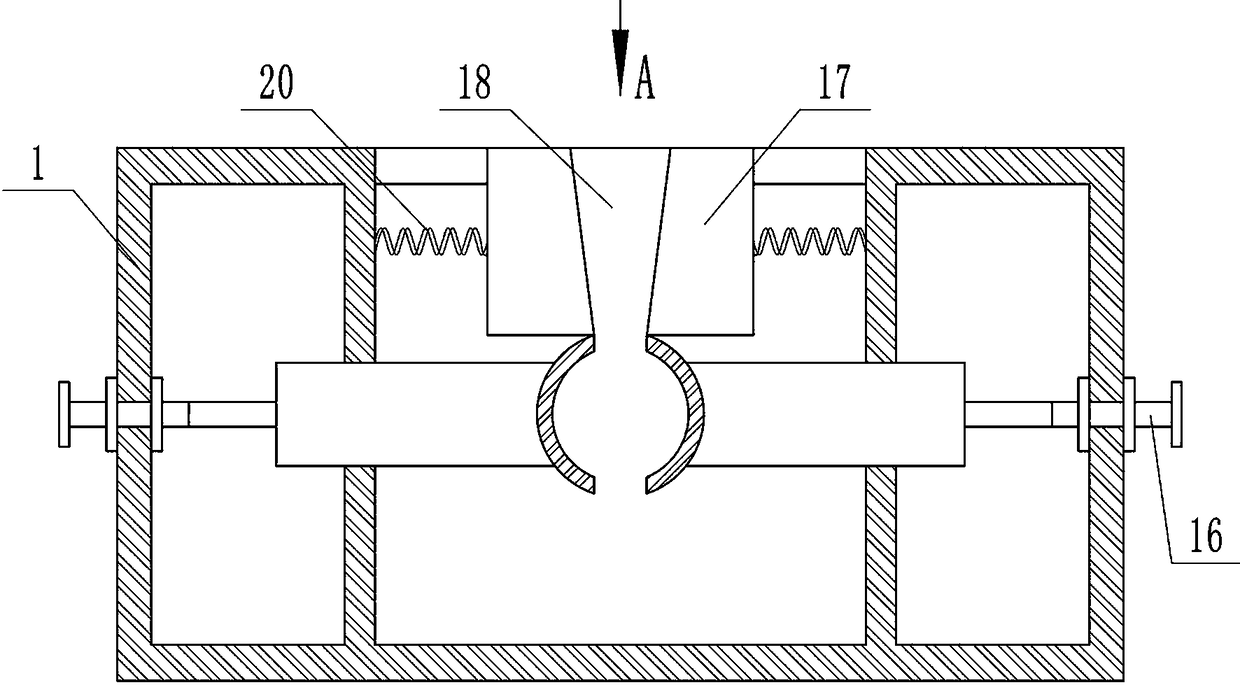

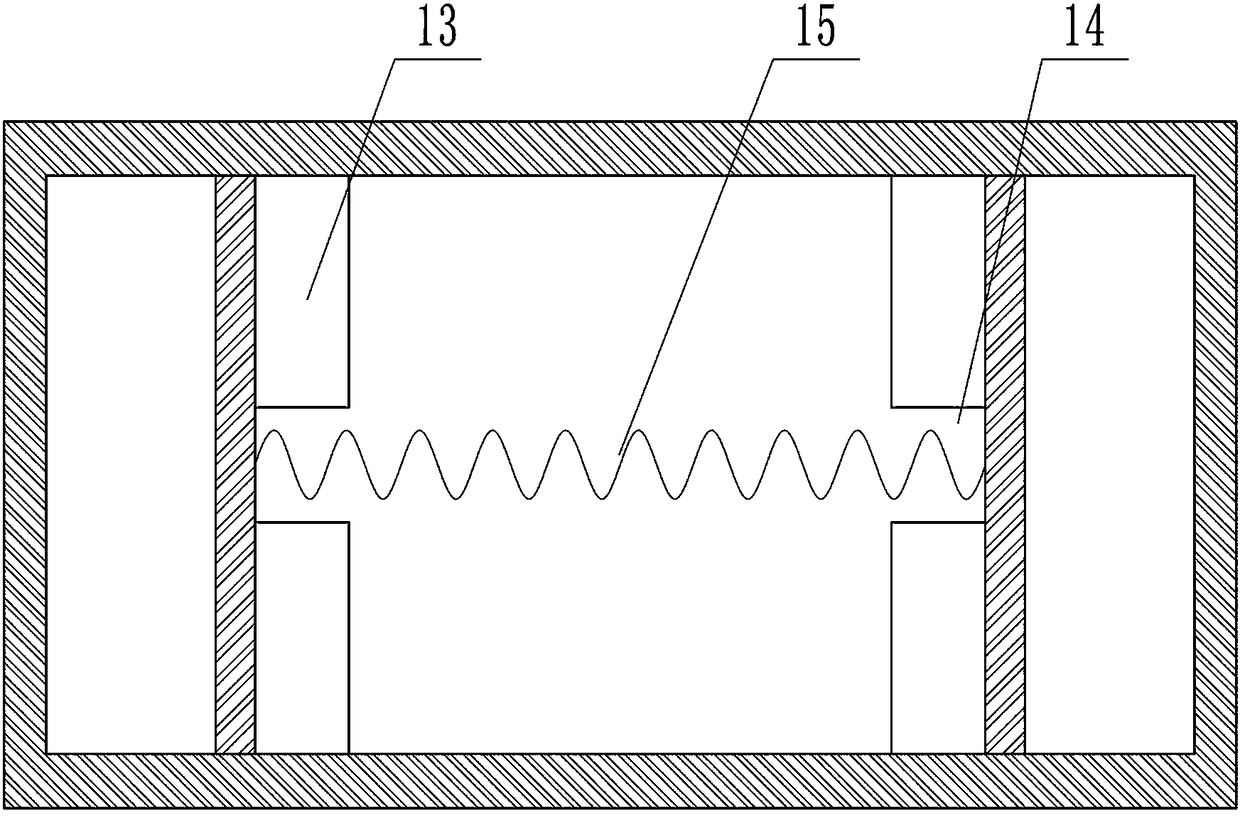

[0017] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] Depend on Figure 1-7 It can be seen that the present invention includes a supporting frame 1, the lower end of the supporting frame 1 is provided with a bottom plate 2, the upper end of the supporting frame 1 is provided with a cover plate 3, and the inner upper part of the supporting frame 1 is provided with a clamping device placed below the cover plate 3, and the clamping device is placed At the central position of the support frame 1 in the left and right direction, the clamping device is composed of two blocks 4 that can move left and right, and the two blocks 4 are symmetrically arranged left and right, and each block 4 includes a semicircular arc block 5, The semicircular inner surfaces of the two arc-shaped blocks 5 are opposite, and the outer surface of each arc-shaped block 5 is connected with two horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com