Multifunctional conveying device based on glass panel production line

A multi-functional conveying, glass panel technology, applied in the direction of conveyor objects, transportation and packaging, furnaces, etc., can solve the problems of space, stability, size limitation of the whole machine, etc., and achieve the effect of compact structure, reduced weight, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

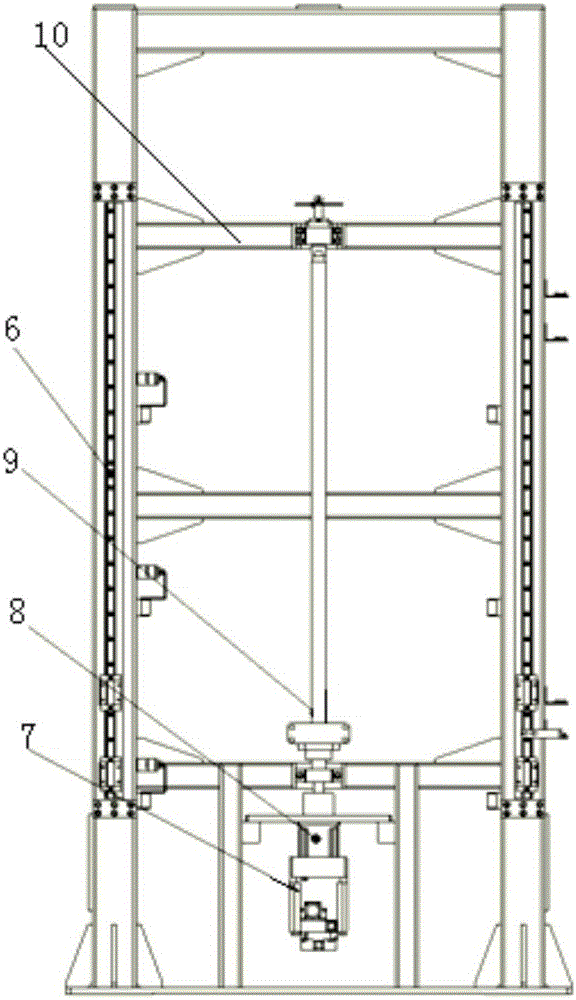

[0021] Referring to the accompanying drawings, a multifunctional conveying device based on a glass panel production line includes an integral lifting device 2 installed on a mechanism frame 1, a roller conveying device 3, a glass rotating and lifting device 4, and a device bottom frame 5; the device bottom frame 5 An integral lifting device 2 is installed at both ends, and the glass rotation and lifting device 4 is installed on the integral lifting device 2. The integral lifting device 2 includes linear guide rails 6 on both sides and a servo motor 7. The servo motor 7 drives the ball through the reducer 8. The screw mandrel 9 rotates, and the linear guide rails 6 on both sides are equipped with an elevating seat 10, and the roller conveying device 3 is fixedly connected with the elevating seat 10, and the elevating seat 10 converts the rotary mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com