Device for transferring and conveying yarn bags

A yarn bag and equipment technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as increasing site area requirements and unfavorable close matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments.

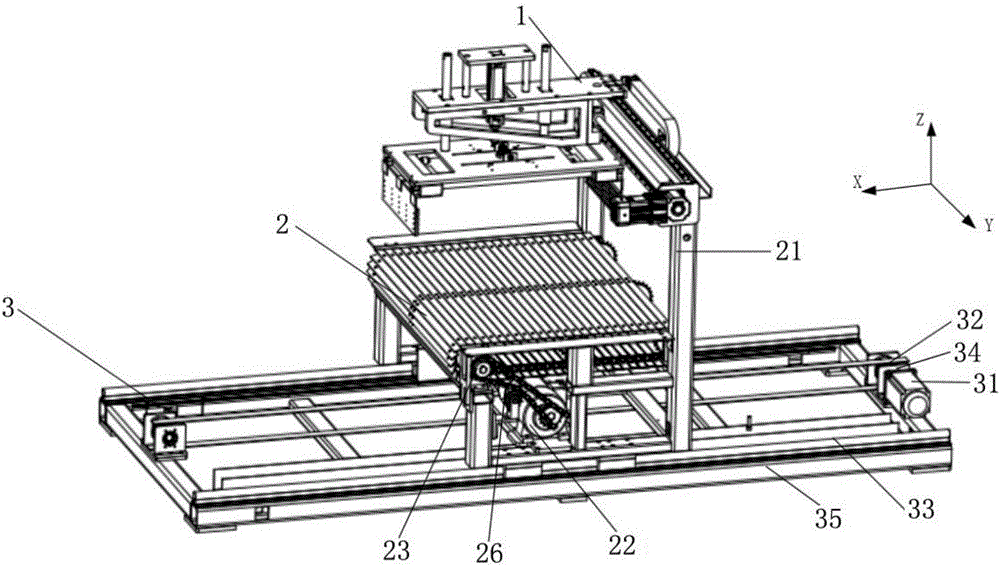

[0027] A device for transferring and transporting yarn bags, such as figure 1 As shown, it includes a bag pushing mechanism 1 for moving the yarn bag in the X-axis and Z-axis directions, a transfer trolley 2 for moving the yarn bag on the Y-axis, and a transfer trolley 2 for walking in the Y-axis direction The track mechanism 3, the yarn bag full of products is transferred from the previous process to the middle end of the transfer trolley 2 through the chain plate, the transfer trolley 2 moves to the set working position through the track mechanism 3, and finally passes through the bag pushing mechanism 1 Transport the finished yarn bags to the entrance of the next process.

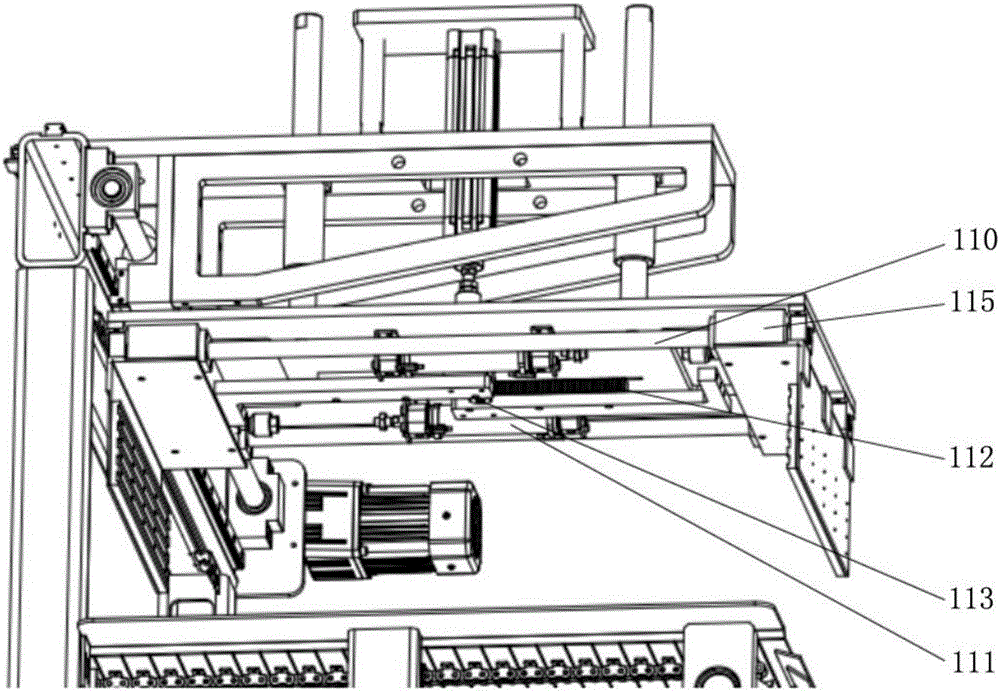

[0028] Described transplanting trolley is provided with mobile frame 21 and translation device, and translation device is used to transfer yarn bag to the middle end of transfer trolley 2, and track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com