Walking mechanism, robot provided with same and self-walking grass cutter

A traveling mechanism and traveling wheel technology, used in agricultural machinery, implements, instruments, cutters, etc., can solve problems such as jitter, sideslip, and slippage, improve walking and work efficiency, avoid slippage, and travel smoothly and reliably. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

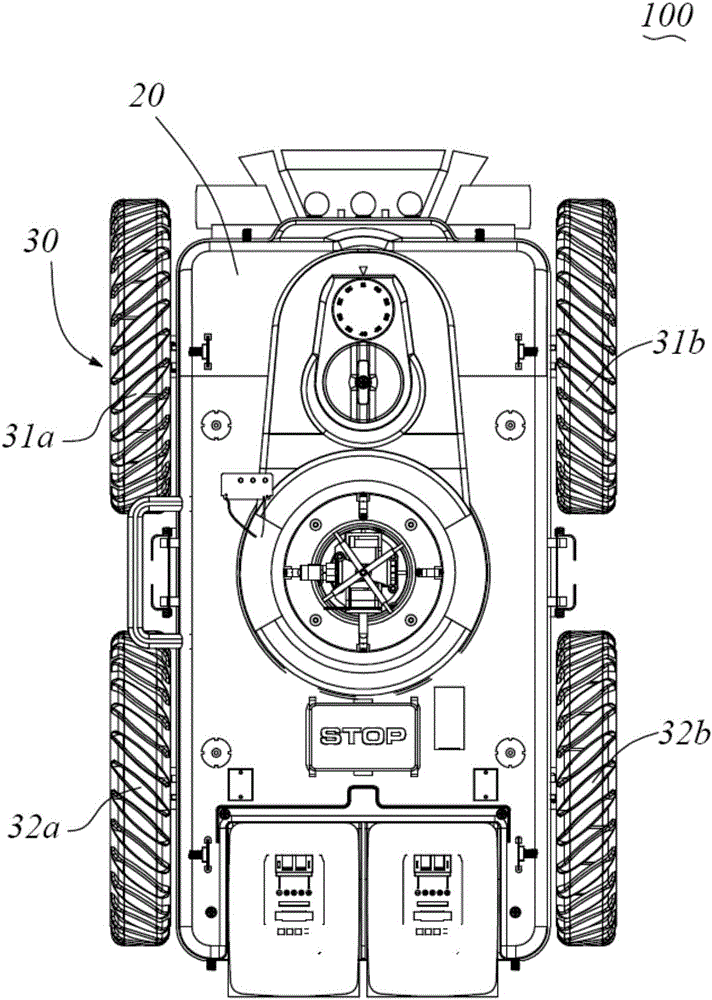

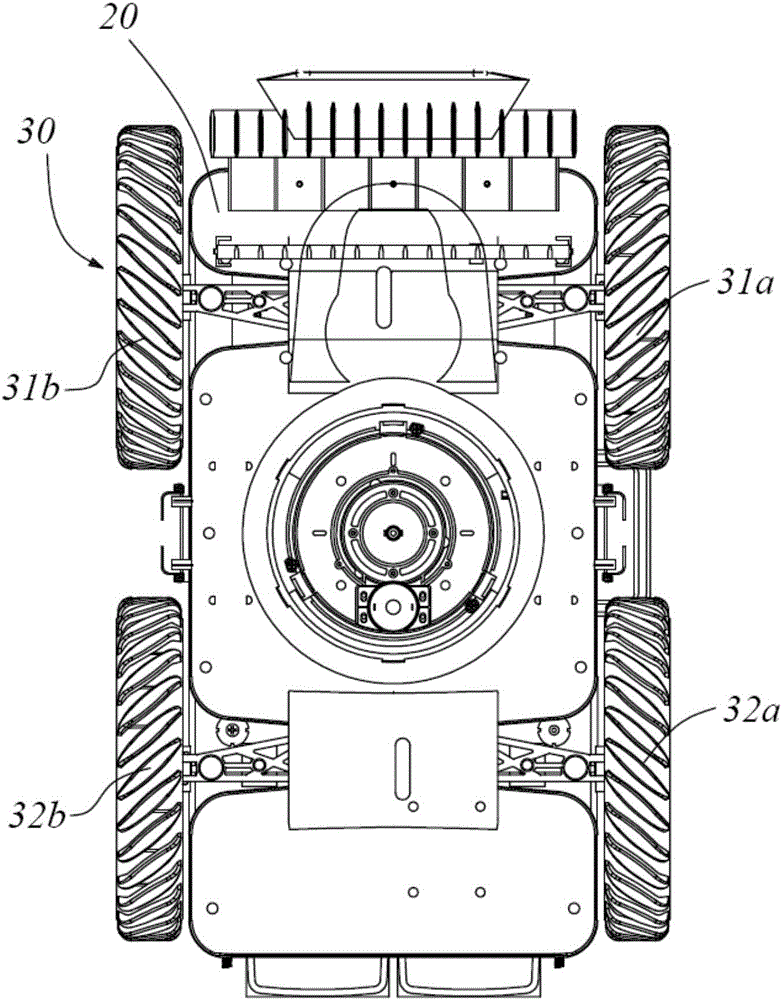

[0040] refer to Figure 1 to Figure 3 As shown, in a preferred embodiment of the present invention, the robot is preferably a mowing robot 100 (or called a self-propelled lawn mower). The mowing robot 100 includes a body 20 and a walking mechanism 30 installed on the body. The walking mechanism 30 includes walking The wheel set and the walking motor (not shown) driving the walking wheel set, the mowing robot 100 supplies power to the walking motor by using a cordless power supply, such as a battery pack, a solar panel, etc. Of course, a wired power supply can also be used to connect to the mains power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com