Royal jelly product preparation and storage method

A preservation method and royal jelly technology, which are applied in the field of preparation and preservation of royal jelly, can solve the problems of melting and taking out the royal jelly, and achieve the effects of reducing the process of taking out the royal jelly, improving the success rate, and improving the antibacterial property.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment one: a kind of preparation method of royal jelly product, comprises the following steps:

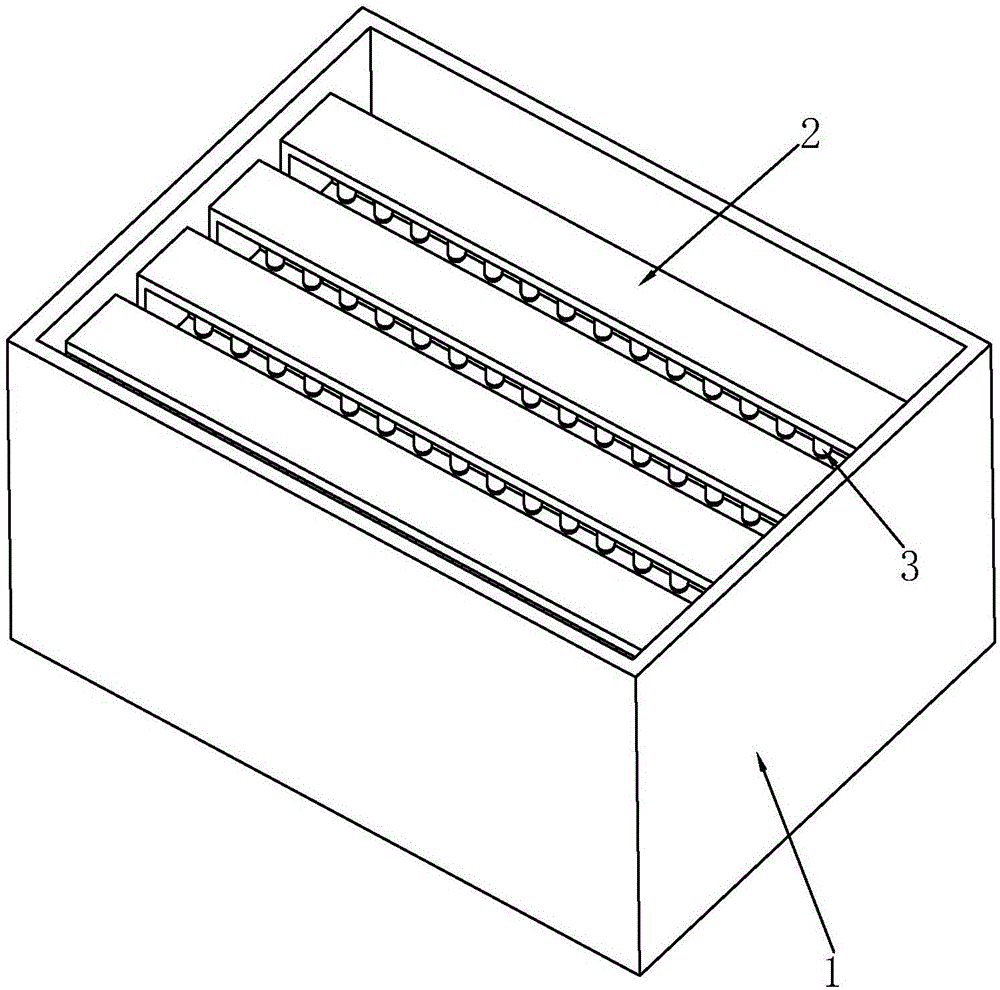

[0040] Make the pulp production frame: the pulp production frame 2 comprises an outer frame 21, and four parallel spacers 22 fixed in the outer frame 21 form, and the outer frame 21 and the spacer 22 are all made of wood (such as figure 1 and figure 2 shown). Use beeswax to make a platform 31 at intervals of 1cm on each spacer 22, make 15 platform 31 on each spacer 22, the diameter of platform 31 is 1.5cm, and the height of platform 31 is 1cm;

[0041] Insect transplantation: each base 31 is coated with a layer of royal jelly, and one bee larva is moved in, and four pulp-producing frames 2 are placed side by side in the beehive 1. When the pulp-producing frames 2 are put into the beehive 1, the base 31 The opening faces downwards, and the interval between the slurry producing frames 2 is 3cm;

[0042] Preparation of royal jelly: After the pulp production frame 2 is ...

Embodiment 2

[0044] Embodiment two: a kind of preparation method of royal jelly product, comprises the following steps:

[0045] Making the pulp production frame: the pulp production frame 2 includes an outer frame 21 and four parallel spacers 22 fixed in the outer frame 21. The outer frame 21 and the spacers 22 are all made of plastic. Use edible wax to make a base 31 at an interval of 2cm on each spacer 22, make 20 bases 31 on each spacer 22, the diameter of the base 31 is 1.5cm, and the height of the base 31 is 1.5cm;

[0046] Migration: Each platform 31 is coated with a layer of royal jelly, and 1 bee larva is moved in, and 5 pulp-producing frames 2 are placed side by side in the beehive 1. When the pulp-producing frames 2 are placed in the beehive 1, the platform 31 The opening faces downwards, and the interval between the slurry producing frames 2 is 3cm;

[0047] Preparation of royal jelly: After the pulp production frame 2 is put into the beehive 1, the bees in the beehive 1 injec...

Embodiment 3

[0049] Embodiment three: a kind of preparation method of royal jelly product, comprises the following steps:

[0050]Making the pulp production frame: the pulp production frame 2 consists of an outer frame 21 and four parallel spacers 22 fixed in the outer frame 21. The outer frame 21 and the spacers 22 are all made of wood. Use beeswax to make a platform 31 at intervals of 1cm on each spacer 22, make 18 platform 31 on each spacer 22, the diameter of platform 31 is 1.5cm, and the height of platform 31 is 1cm;

[0051] Migration: Each platform 31 is coated with a layer of royal jelly, and 1 bee larva is moved in, and 5 pulp-producing frames 2 are placed side by side in the beehive 1. When the pulp-producing frames 2 are placed in the beehive 1, the platform 31 The opening faces downwards, and the interval between the slurry producing frames 2 is 3cm;

[0052] Preparation of royal jelly: After the pulp production frame 2 is put into the beehive 1, the bees in the beehive 1 inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com